Feb . 05, 2025 01:58

Back to list

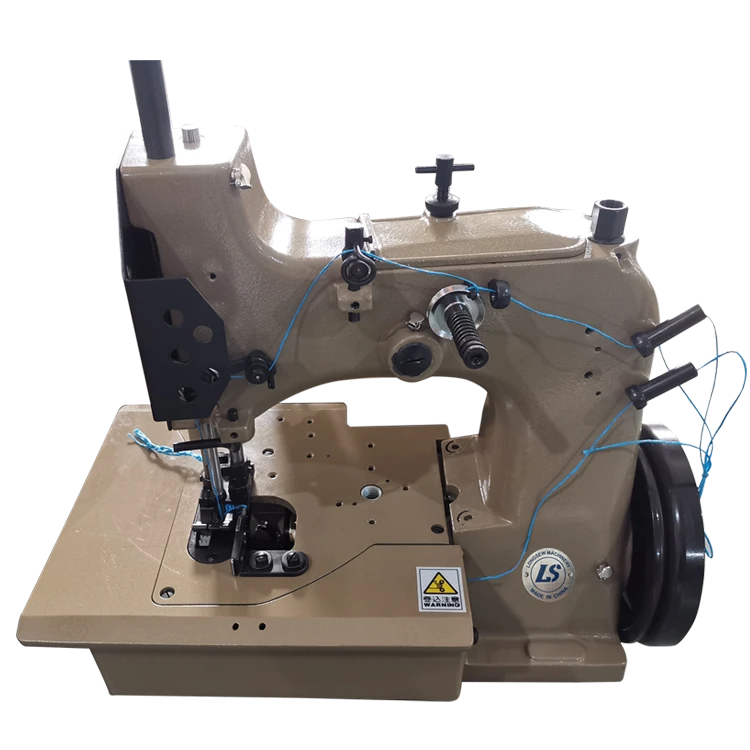

automatic stitching machine price

The world of textile manufacturing has seen an impressive evolution with the introduction of automatic stitching machines. As businesses strive to enhance productivity and precision, the price of automatic stitching machines becomes a central topic of interest. This article delves deeply into the various factors influencing the pricing of these sophisticated machines, offering both a professional and real-world perspective to help you make informed purchasing decisions.

Additionally, the extent of automation and versatility in an automatic stitching machine is a significant driving force behind its price. Machines that offer a broader range of stitching options, adaptable to various fabrics and complex designs, naturally attract a higher cost. Textile businesses must assess whether investing in a multi-functional machine aligns with their production diversity and objectives. For those hesitating due to price concerns, the second-hand market or leasing options offer alternative solutions. Businesses can opt for used machines that are refurbished and sold at a fraction of the new machine price. However, this requires thorough inspection and validation of the machine's condition to avoid unforeseen repair costs. Leasing, on the other hand, minimizes upfront costs while providing access to advanced technology, allowing businesses to upgrade more frequently as new models become available, thus remaining competitive. Assessing the long-term value of investing in an automatic stitching machine involves evaluating not only its purchase price but also its impact on productivity, fabric quality, and operational efficiency. Engaging with industry experts and consulting professional reviews can provide authoritative insights and increase trust in potential purchases. Testimonials from businesses using similar machinery can add an experiential dimension to decision-making, showcasing the transformative impact of these machines in real-world settings. As the textile industry continues to embrace technological advancements, automatic stitching machines will remain a pivotal component shaping production processes. Price will always be a consideration, but understanding the full spectrum of benefits and the factors influencing costs can empower textile businesses to make informed, strategic investments tailored to their specific needs and goals. In conclusion, while the price tag may seem daunting, the return on investment and potential for enhanced productivity often justify the outlay, positioning businesses for long-term success in an increasingly competitive marketplace.

Additionally, the extent of automation and versatility in an automatic stitching machine is a significant driving force behind its price. Machines that offer a broader range of stitching options, adaptable to various fabrics and complex designs, naturally attract a higher cost. Textile businesses must assess whether investing in a multi-functional machine aligns with their production diversity and objectives. For those hesitating due to price concerns, the second-hand market or leasing options offer alternative solutions. Businesses can opt for used machines that are refurbished and sold at a fraction of the new machine price. However, this requires thorough inspection and validation of the machine's condition to avoid unforeseen repair costs. Leasing, on the other hand, minimizes upfront costs while providing access to advanced technology, allowing businesses to upgrade more frequently as new models become available, thus remaining competitive. Assessing the long-term value of investing in an automatic stitching machine involves evaluating not only its purchase price but also its impact on productivity, fabric quality, and operational efficiency. Engaging with industry experts and consulting professional reviews can provide authoritative insights and increase trust in potential purchases. Testimonials from businesses using similar machinery can add an experiential dimension to decision-making, showcasing the transformative impact of these machines in real-world settings. As the textile industry continues to embrace technological advancements, automatic stitching machines will remain a pivotal component shaping production processes. Price will always be a consideration, but understanding the full spectrum of benefits and the factors influencing costs can empower textile businesses to make informed, strategic investments tailored to their specific needs and goals. In conclusion, while the price tag may seem daunting, the return on investment and potential for enhanced productivity often justify the outlay, positioning businesses for long-term success in an increasingly competitive marketplace.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025