Efficient Shoe Stitching with Advanced Automatic Sewing Machines for Optimal Performance

The Evolution and Impact of Automatic Shoe Sewing Machines

The footwear industry has seen significant transformations over the years, particularly in the realm of manufacturing technology. One of the key innovations that has propelled this industry forward is the automatic shoe sewing machine. These machines have not only improved productivity but have also enhanced the quality and consistency of shoe production. In an era where efficiency and precision are paramount, understanding the evolution and impact of automatic shoe sewing machines becomes essential.

Historical Context

The journey of shoe manufacturing has deep roots, dating back thousands of years. Initially, shoes were handcrafted, relying heavily on skilled artisans who meticulously sewed each piece of fabric and leather together. This process, while artisanal, was labor-intensive and time-consuming. As the Industrial Revolution ushered in new technological advancements, the footwear sector began exploring mechanization. The introduction of the first sewing machines in the 19th century marked the beginning of a significant shift in how shoes were produced.

By the mid-20th century, as consumer demand skyrocketed, the need for faster production rates became critical. This led to the development of specialized sewing machines designed to automate various aspects of shoe manufacturing. The advent of automatic shoe sewing machines was a game changer, enabling manufacturers to produce shoes at an unprecedented pace while maintaining high standards of quality.

The Mechanism Behind Automatic Shoe Sewing Machines

Automatic shoe sewing machines are sophisticated pieces of equipment engineered to handle the complexities of footwear assembly. These machines can perform multiple tasks, including stitching, trimming, and sometimes even finishing operations, all in a seamless process. They are equipped with advanced features such as computerized controls, which allow operators to program precise stitching patterns, adjust parameters based on different materials, and switch between various tasks with ease.

The integration of robotics and artificial intelligence has further enhanced the capabilities of these machines. Advanced sensors enable them to detect discrepancies in material thickness and texture, ensuring that the sewing process adapts accordingly. This level of precision not only reduces waste but also minimizes the likelihood of defects, contributing to a higher quality end product.

Benefits of Automatic Shoe Sewing Machines

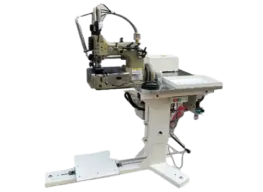

automatic shoe sewing machine

The advantages of employing automatic shoe sewing machines in footwear production are manifold. First and foremost, these machines drastically increase production speed. Where a skilled worker may take hours to complete a single pair of shoes, an automatic sewing machine can accomplish the same task in a fraction of the time. This efficiency translates into significant cost savings for manufacturers, allowing them to scale up production and meet rising consumer demand.

Moreover, the consistency of output is a crucial benefit. Human error can lead to variability in the quality of sewn products, but automatic machines deliver uniform stitching and precision in every shoe. This is particularly important in large-scale manufacturing, where consistency is key to maintaining brand reputation.

Another vital aspect is labor reduction. While some may view this as a downside, the reality is that it allows workers to transition to more skilled roles that require oversight, quality control, and machine maintenance. This shift not only uplifts the quality of jobs but also encourages workforce development in the industry.

Challenges and Future Directions

Despite their many benefits, the implementation of automatic shoe sewing machines is not without challenges. The initial investment in such machinery can be considerable, posing a barrier for smaller manufacturers. Additionally, training the workforce to operate and maintain these advanced machines is essential to maximize their potential.

Looking toward the future, the ongoing advancement of technology, including developments in AI and machine learning, holds promise for even greater efficiencies in shoe manufacturing. As sustainability becomes a critical focus in the industry, automatic sewing machines may evolve to incorporate eco-friendly practices, further reducing waste and energy consumption.

Conclusion

In conclusion, automatic shoe sewing machines represent a remarkable evolution in the footwear industry. They have transformed the way shoes are manufactured, offering speed, consistency, and cost-effectiveness that benefits both producers and consumers. As technology continues to advance, the future of shoe production looks promising, with automation leading the way toward a more efficient and sustainable industry. With ongoing innovation, automatic shoe sewing machines will likely remain a cornerstone of footwear manufacturing for years to come.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025