Automatic Footwear Stitching Machine for Efficient Shoe Manufacturing Solutions

The Evolution and Impact of Automatic Shoe Sewing Machines

The world of footwear manufacturing has seen significant advancements over the past decades, particularly with the introduction of automatic shoe sewing machines. These machines represent a paradigm shift in the way shoes are produced, enhancing efficiency, precision, and the overall quality of the final product. This article explores the evolution of automatic shoe sewing machines, their functionality, and their impact on the footwear industry.

The Evolution of Shoe Manufacturing

Historically, shoe manufacturing was a labor-intensive process that required skilled workers to sew and assemble every component by hand. The Industrial Revolution marked the beginning of mechanized manufacturing, with the first shoe-making machines introduced in the 19th century. These early models used basic mechanical principles to streamline the production of shoes, significantly reducing the time and labor required.

As technology progressed, the introduction of computer numerical control (CNC) and automation transformed the landscape of shoe production. Automatic shoe sewing machines emerged as a sophisticated solution that not only speeds up the sewing process but also offers an unprecedented level of accuracy and consistency. With features like automatic threading, adjustable stitch length, and programmable patterns, these machines can handle a wide variety of materials and designs, making them invaluable in modern factories.

How Automatic Shoe Sewing Machines Work

Automatic shoe sewing machines utilize advanced technology to facilitate various sewing tasks involved in shoe production. These machines are equipped with computer systems that allow operators to program specific sewing patterns, which can be stored and recalled for future use. This programmability is critical, as it enables manufacturers to switch between different styles and designs with ease.

The sewing process is further enhanced by precision sensors and automated feeders that ensure materials are aligned correctly before stitching begins. Many models also feature automatic cutting capabilities, which streamline the process of trimming excess material after sewing.

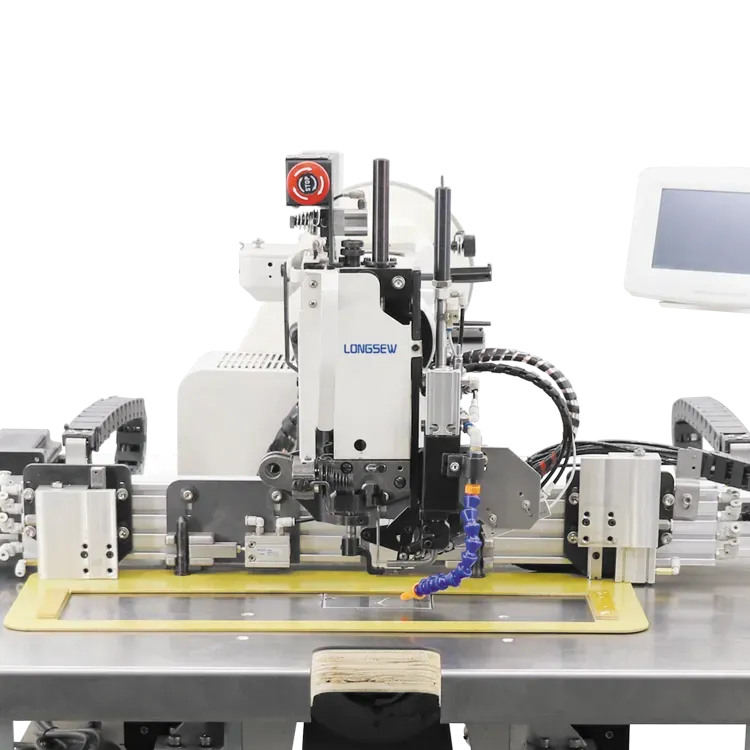

automatic shoe sewing machine

Moreover, contemporary automatic shoe sewing machines often incorporate robotics, resulting in even greater efficiencies. Robotic arms can move materials precisely into position, ensuring that every stitch is placed accurately. The use of artificial intelligence and machine learning is also on the rise, allowing machines to analyze production data and optimize their performance over time.

The Impact on the Footwear Industry

The introduction of automatic shoe sewing machines has had a transformative impact on the footwear industry. One of the most significant advantages is the speed at which shoes can be produced. With automation, manufacturers can produce a higher volume of shoes in less time, which is crucial in a fast-paced market that demands quick turnaround times.

Additionally, these machines contribute to improved quality control. Manual sewing often leads to human error, which can result in inconsistencies in the final product. Automatic machines, however, provide uniform stitches and consistent quality, reducing the risk of defects and waste.

Cost efficiency is another major benefit. While the initial investment in automatic sewing machines may be substantial, the long-term savings in labor costs and material waste justify the expenditure. Moreover, the ability to produce more shoes in less time allows companies to respond to market trends promptly, providing them with a competitive edge.

Furthermore, the use of automatic shoe sewing machines has opened up new possibilities for customization. Brands can now offer bespoke designs, tailored to individual customer preferences, without significantly increasing production time or costs. This shift toward personalized products is changing consumer expectations and driving innovation within the industry.

Conclusion

In conclusion, automatic shoe sewing machines are revolutionizing the footwear industry by enhancing efficiency, precision, and product quality. The evolution of these machines reflects broader trends in manufacturing that prioritize automation and technological advancement. As the demand for faster and more customizable footwear continues to grow, the role of automatic shoe sewing machines will undoubtedly become increasingly central to successful shoe manufacturing operations. As the industry embraces these innovations, we can expect to see exciting developments in shoe design and production processes in the years to come.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025