automatic sewing machine industrial

The Evolution and Impact of Automatic Sewing Machines in the Industrial Sector

The industrial landscape has witnessed remarkable transformations over the past century, and one of the most significant advancements is the development of automatic sewing machines. These machines have revolutionized the garment manufacturing process, enhancing productivity, precision, and efficiency in ways that were previously unimaginable. This article explores the evolution of automatic sewing machines, their various functions, and their impact on the textile industry.

Historical Context

The origins of sewing machines can be traced back to the early 19th century, when innovators like Elias Howe and Isaac Merritt Singer developed the first commercial machines. However, it was not until the introduction of electric and automatic features in the mid-20th century that the industrial sewing machine began to flourish. Automatic sewing machines have evolved from simple manual models to sophisticated digital systems capable of executing complex tasks with minimal human intervention.

Types of Automatic Sewing Machines

Automatic sewing machines come in various forms, each designed to meet specific industrial needs. Some of the most common types include

1. Lockstitch Machines These are the most prevalent type of sewing machine used in the garment industry. They create a strong stitch by interlocking two threads and are ideal for sewing various fabrics.

2. Overlock Machines These machines are used to sew seams and finish the edges of fabrics to prevent fraying. Their ability to trim fabric while sewing makes them essential for high-speed garment production.

3. Flatlock Machines Commonly used in the production of activewear, flatlock machines enable the creation of flat seams that reduce chafing, providing comfort to athletes and active individuals.

automatic sewing machine industrial

5. Multi-needle Machines Used for various applications, including quilting and stitching multiple layers, these machines have numerous needles and can perform multiple functions in one pass, significantly speeding up the production process.

Advantages of Automatic Sewing Machines

The introduction of automatic sewing machines in industrial settings has provided numerous advantages. Firstly, they significantly increase production speed. Traditional sewing processes often require skilled laborers to manually operate machines, which can be time-consuming. Automatic machines reduce the need for continuous human input, allowing manufacturers to produce large quantities of garments in a fraction of the time.

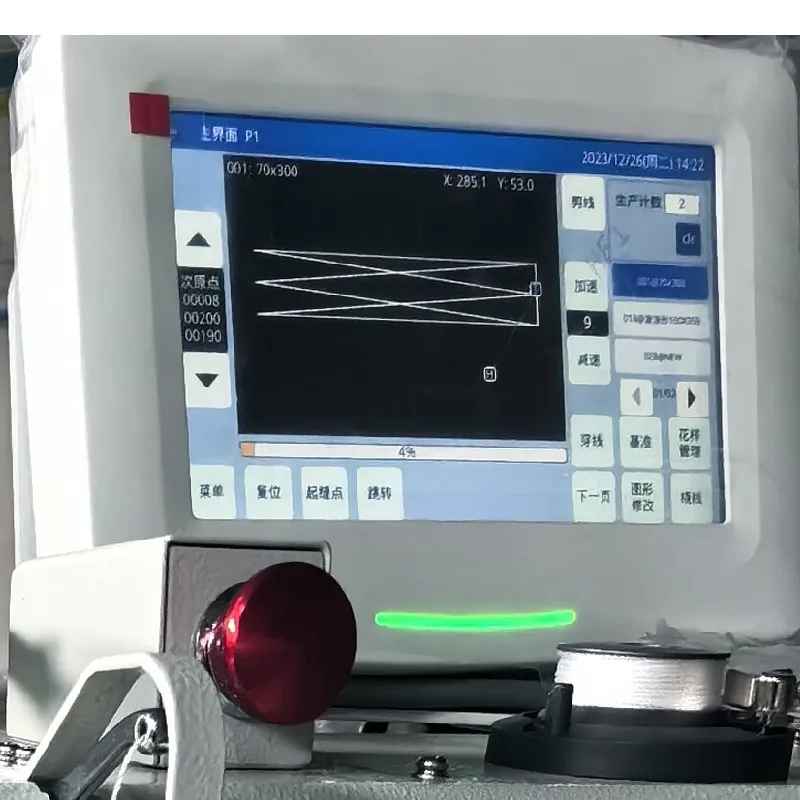

Secondly, automatic sewing machines offer enhanced precision and consistency. With digitized settings and programmable functions, these machines can execute complex patterns and designs with remarkable accuracy. This level of precision is particularly crucial in industries where quality control is paramount.

Furthermore, automatic machines contribute to safety and ergonomics in the workplace. By reducing the need for manual labor, the risk of repetitive strain injuries is diminished. Operators can oversee multiple machines, mitigating fatigue and allowing for a more sustainable working environment.

Impact on the Textile Industry

The impact of automatic sewing machines on the textile industry cannot be overstated. As manufacturers have embraced automation, they have been able to reduce production costs while improving output quality. This shift has enabled companies to respond more adeptly to market demands and maintain a competitive edge in a rapidly evolving global market.

Moreover, the integration of automatic sewing machines has sparked innovations in fabric and garment design. With the ability to execute intricate patterns quickly, designers are encouraged to push the boundaries of creativity, resulting in more diverse and unique products.

Conclusion

The advent of automatic sewing machines has profoundly transformed the industrial sewing landscape. Through increased efficiency, precision, and safety, these machines have not only streamlined the garment manufacturing process but also paved the way for innovative design practices. As technology continues to advance, the role of automatic sewing machines will only become more central to the textile industry's future, ultimately shaping the way we produce and consume clothing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025