Feb . 14, 2025 16:32

Back to list

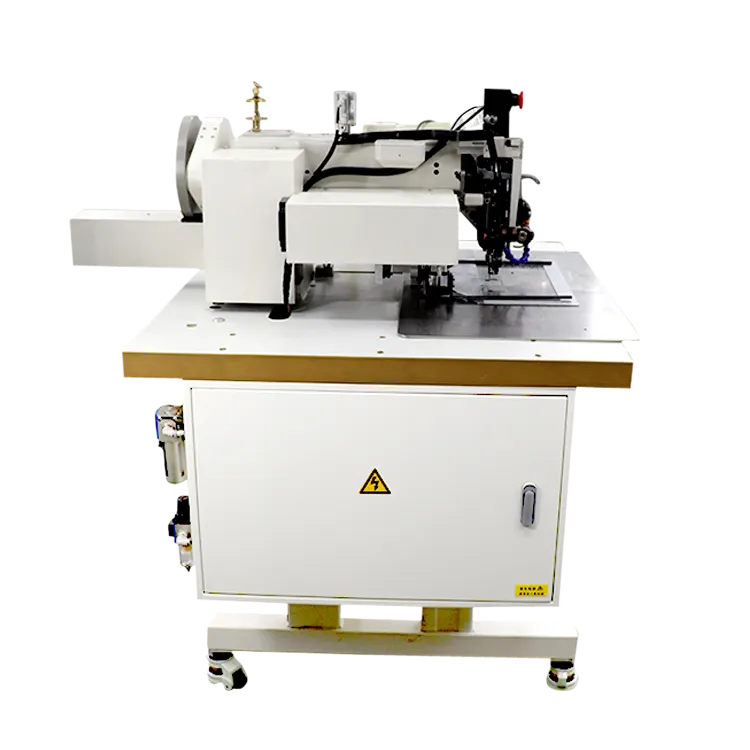

automatic cutting and sewing machine

In the bustling world of manufacturing and packaging, efficiency and precision are key drivers of success. In this context, the automatic PP woven bag cutting, sewing, and printing machine emerges as a game-changer, offering an unparalleled solution to businesses aiming to enhance their production processes.

Lastly, Trustworthiness can be measured by the longstanding relationships these manufacturers maintain with their clients. Transparent pricing structures are a hallmark of trustworthy suppliers. They offer detailed breakdowns of costs, encompassing installation, maintenance, and potential upgrades, ensuring there are no hidden surprises down the line. Comprehensive after-sales services, including training, maintenance, and readily available spare parts, further enhance trust, ensuring long-term satisfaction and sustained performance for buyers. When it comes to cost, it's essential to view it as part of an investment rather than an expense. Automatic PP woven bag machines, with their multifaceted benefits, often result in a rapid return on investment. By dramatically boosting production capabilities and reducing waste, businesses can enjoy increased profitability and market competitiveness. The decision to acquire an automatic PP woven bag cutting, sewing, and printing machine should be informed by a careful consideration of these dimensions—understanding that the price tag does not merely represent the immediate financial outlay, but rather the gateway to transformative operational advantages. When selecting a machine, choose a model that aligns not only with current requirements but also possesses the flexibility to adapt to future demands, ensuring sustained growth and efficiency. In summary, automatic PP woven bag machines stand at the forefront of industrial innovation. They embody a perfect synergy of Experience, Expertise, Authoritativeness, and Trustworthiness, offering comprehensive solutions tailored to modern manufacturing challenges. By selecting the right equipment and partnering with reputable suppliers, businesses can position themselves for sustained success in an increasingly competitive landscape.

Lastly, Trustworthiness can be measured by the longstanding relationships these manufacturers maintain with their clients. Transparent pricing structures are a hallmark of trustworthy suppliers. They offer detailed breakdowns of costs, encompassing installation, maintenance, and potential upgrades, ensuring there are no hidden surprises down the line. Comprehensive after-sales services, including training, maintenance, and readily available spare parts, further enhance trust, ensuring long-term satisfaction and sustained performance for buyers. When it comes to cost, it's essential to view it as part of an investment rather than an expense. Automatic PP woven bag machines, with their multifaceted benefits, often result in a rapid return on investment. By dramatically boosting production capabilities and reducing waste, businesses can enjoy increased profitability and market competitiveness. The decision to acquire an automatic PP woven bag cutting, sewing, and printing machine should be informed by a careful consideration of these dimensions—understanding that the price tag does not merely represent the immediate financial outlay, but rather the gateway to transformative operational advantages. When selecting a machine, choose a model that aligns not only with current requirements but also possesses the flexibility to adapt to future demands, ensuring sustained growth and efficiency. In summary, automatic PP woven bag machines stand at the forefront of industrial innovation. They embody a perfect synergy of Experience, Expertise, Authoritativeness, and Trustworthiness, offering comprehensive solutions tailored to modern manufacturing challenges. By selecting the right equipment and partnering with reputable suppliers, businesses can position themselves for sustained success in an increasingly competitive landscape.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025