Automatic Fabric Cutting and Sewing Machine for Efficient Production

The Rise of Automatic Cutting Sewing Machines in the Textile Industry

In recent years, the textile industry has witnessed a remarkable transformation driven by advancements in technology. Among the most significant innovations are automatic cutting sewing machines, which have revolutionized the way garments are produced. These machines integrate cutting and sewing processes, enhancing efficiency and accuracy in apparel manufacturing.

Automatic cutting sewing machines are engineered to streamline the production process. Traditional methods often require multiple steps, where fabric is cut manually before being sewn together by different machines. This method can be time-consuming and prone to human error. In contrast, automatic cutting sewing machines consolidate these steps into a single operation, drastically reducing the time required to produce garments. By automating the cutting and sewing processes, manufacturers can achieve higher production rates and meet the increasing demands of fast fashion.

The precision of automatic cutting sewing machines is another significant advantage. These machines use advanced technology, such as computer numerical control (CNC) and laser cutting, which ensures precise cuts and consistent stitching. This level of accuracy not only enhances the overall quality of the final product but also minimizes fabric waste, making the production process more sustainable. As sustainability becomes a critical concern in the textile industry, the efficiency of these machines aligns perfectly with the need to reduce waste.

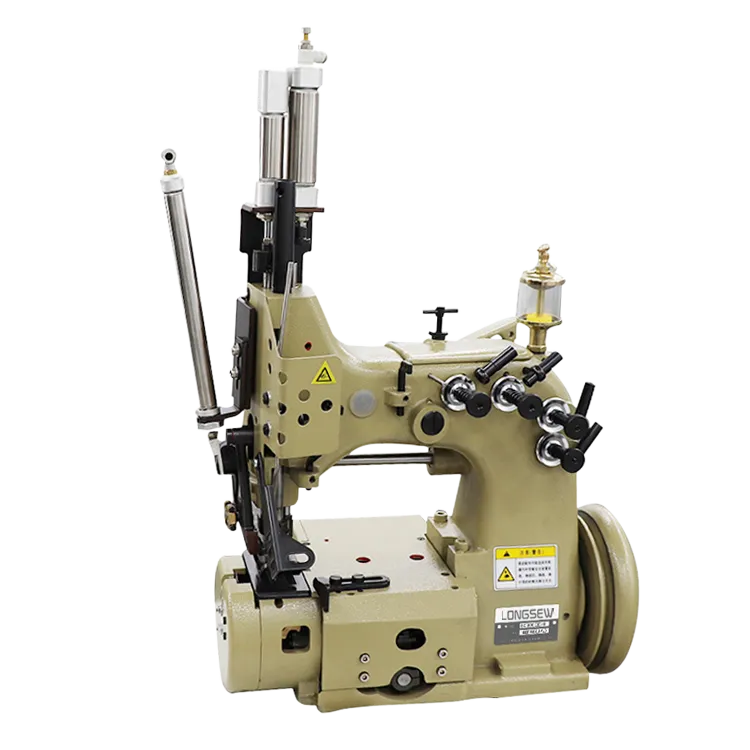

automatic cutting sewing machine

Additionally, automatic cutting sewing machines greatly enhance safety in the workplace. Traditional cutting methods can pose various hazards to operators, with the risk of accidents occurring during manual cutting and sewing. By automating these processes, the machines reduce the chances of injuries and provide a safer working environment for employees.

Furthermore, the versatility of these machines cannot be overlooked. They are equipped to handle a wide range of fabrics and designs, making them suitable for various applications in the fashion industry, from high-end couture to mass-produced garments. This flexibility allows businesses to adapt quickly to changing market trends and consumer preferences.

While the initial investment in automatic cutting sewing machines may be significant, the long-term benefits they offer make them a worthwhile consideration for textile manufacturers. Businesses that adopt this technology not only improve their operational efficiency and product quality but also gain a competitive edge in a rapidly evolving market.

In conclusion, automatic cutting sewing machines represent a critical advancement in the textile industry, addressing the challenges of efficiency, precision, safety, and sustainability. As the demand for quick and high-quality production continues to grow, these machines are likely to play an increasingly vital role in shaping the future of garment manufacturing. Embracing this technology is essential for businesses looking to thrive in the modern fashion landscape.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025