Automatic Button Control for Efficient Sewer Management Solutions

The Automated Button Sewer Revolutionizing Fashion and Garment Manufacturing

In today’s fast-paced world, technology is rapidly evolving and reshaping various industries, and fashion is no exception. Innovations in garment manufacturing are streamlining processes, enhancing quality, and reducing waste. One such remarkable innovation is the automated button sewer, a machine designed to revolutionize how buttons are attached to garments. This article explores the significance of the automated button sewer, its advantages, functionalities, and its impact on the fashion industry.

Understanding the Automated Button Sewer

An automated button sewer is a specialized sewing machine designed to attach buttons to garments efficiently. Unlike traditional button-sewing methods, which are labor-intensive and time-consuming, the automated approach employs robotics and advanced technology to mechanize the entire process. These machines can sew various types of buttons, from plastic to metal, with precision and speed, ensuring consistency in quality across large production runs.

Advantages of Automated Button Sewers

1. Increased Efficiency One of the primary advantages of automated button sew machines is their remarkable efficiency. They can significantly reduce the time taken to sew buttons onto garments, leading to faster production cycles. In an industry where time is money, this efficiency is invaluable.

2. Cost-Effectiveness By minimizing labor costs and reducing fabric waste, automated button sewers can lower overall production costs. The initial investment in automated machinery may seem steep; however, the long-term savings and improved profit margins make it a worthwhile consideration for manufacturers.

3. Enhanced Precision Automated button sew machines utilize advanced technology to ensure precise stitching and placement of buttons. This precision minimizes the risk of human error, which is common in manual sewing processes. As a result, garments produced with automated sewing technology often exhibit higher quality and consistency.

4. Reduced Physical Strain The manual operation of sewing machines can lead to repetitive strain injuries among workers. By automating the button-sewing process, manufacturers can reduce the physical demands on laborers, promoting a safer work environment.

5. Sustainability In an era of growing environmental consciousness, the automated button sewer contributes to sustainability efforts within the fashion industry. By optimizing production processes, reducing waste, and minimizing the use of materials, manufacturers can operate in a more eco-friendly manner.

Functionality of Automated Button Sewers

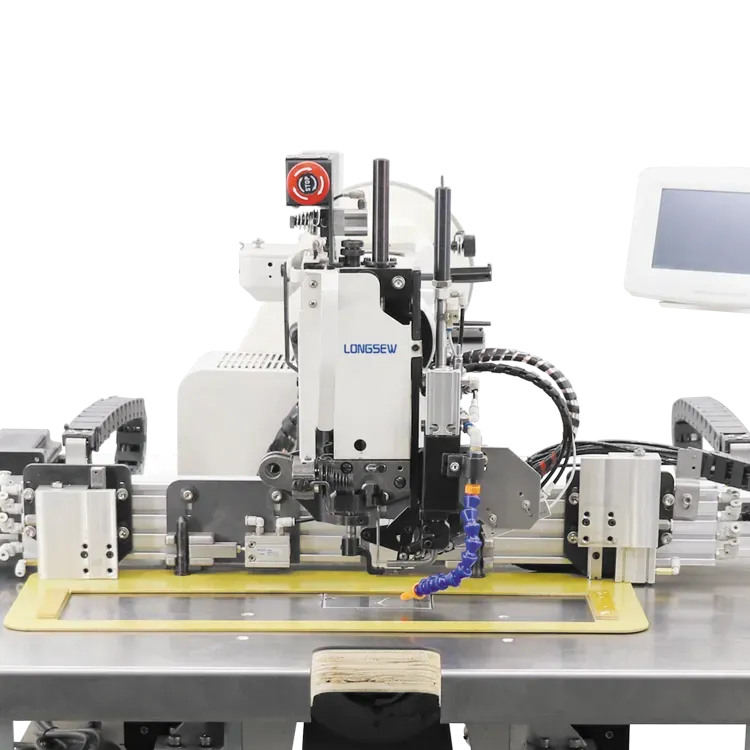

automatic button sewer

Automated button sew machines incorporate various technologies to achieve their high levels of efficiency and precision. Most machines come equipped with

- Robotic Arms These arms position and manipulate buttons with high accuracy, allowing for rapid processing. They can pick up buttons, place them in the correct position, and execute the sewing operation seamlessly.

- Smart Technology Many modern machines are equipped with computer interfaces that allow for easy programming and adjustments. Operators can easily switch between different button types and designs with the touch of a button.

- Sensors and Cameras Some advanced automated button sew machines integrate sensors and camera systems to ensure the correct button size and placement. This technology helps in detecting placement errors and provides real-time feedback.

- Efficient Workflow Integration Automated machines can be integrated into broader production systems, allowing for a seamless workflow from cutting fabric to the final sewing of garments. This integration creates a more streamlined manufacturing process.

The Future of Automated Button Sewers in Fashion

The adoption of automated button sew machines signals a significant shift in the fashion industry. As manufacturers recognize the importance of efficiency and sustainability, many are likely to invest in this technology to remain competitive. While the initial investment may be substantial, the long-term benefits of reduced labor costs, increased production speed, and heightened quality assurance will likely drive widespread adoption.

Moreover, as technology continues to advance, we can expect even more sophisticated automated systems that further enhance garment manufacturing processes. Innovations such as artificial intelligence and machine learning can lead to smarter machines that adapt and optimize settings based on real-time production data.

Conclusion

The automated button sewer exemplifies how technology can transform traditional manufacturing processes in the fashion industry. By increasing efficiency, enhancing precision, and promoting sustainability, automated button sew machines are not only benefiting manufacturers but also setting a new standard for garment quality. As the fashion industry continues to evolve, embracing automation will be crucial for those looking to thrive in an increasingly competitive landscape.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025