Automatic Sewer Button Activation for Efficient Waste Management and Control

The Rise of Automated Button Sewers Transforming Textile Manufacturing

In the ever-evolving world of textile manufacturing, automation continues to play a pivotal role in enhancing efficiency and productivity. Among the innovative advancements, the automatic button sewer stands out as a remarkable technological achievement. This machine has not only transformed the way buttons are affixed to garments but has also reshaped entire production lines, contributing to cost savings and improved work environments.

What is an Automatic Button Sewer?

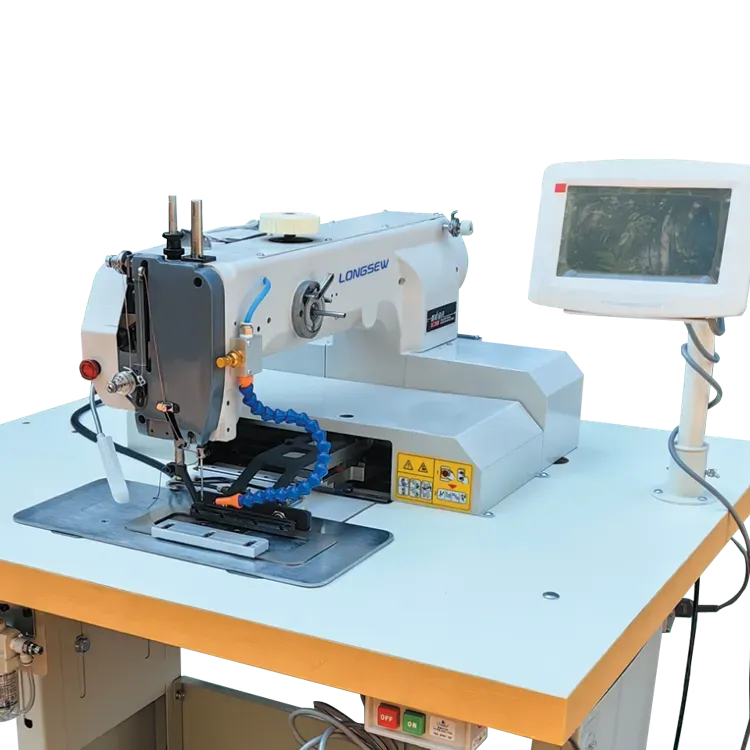

An automatic button sewer is a specialized piece of machinery designed to sew buttons onto fabrics with precision and speed. Traditional methods of sewing buttons are labor-intensive and time-consuming, often requiring skilled workers to perform tasks manually. In contrast, automatic button sewers utilize computerized systems to streamline the process. These machines can quickly and accurately sew a variety of button types, including shank, flat, and specialized button designs, with minimal human intervention.

Advantages of Automation in Button Sewing

1. Increased Efficiency One of the primary benefits of automatic button sewers is the significant increase in speed and efficiency. These machines can sew multiple buttons in mere seconds, dramatically reducing production times. This efficiency allows manufacturers to meet high demands and adapt quickly to changing fashion trends, ensuring that products reach the market promptly.

2. Cost Savings By automating the button-sewing process, manufacturers can reduce labor costs associated with traditional sewing techniques. Fewer workers are needed for the repetitive task of button attachment, which not only saves on wages but also minimizes the risk of human error. This leads to consistent quality and less fabric waste, further enhancing cost-effectiveness.

3. Improved Quality Control Automatic button sewers are equipped with advanced technology that ensures precise placement and stitching of buttons. This minimizes the risk of misaligned or poorly attached buttons, which can lead to garment defects. With automated processes, quality control becomes more manageable, as machines consistently deliver high standards of workmanship.

automatic button sewer

4. Ergonomic Work Environment The reduction of manual labor associated with button sewing contributes to a safer and more ergonomic work environment. Workers are able to focus on more complex tasks, reducing the physical strain that comes with repetitive sewing. This shift not only improves job satisfaction but also fosters a more skilled workforce capable of handling advanced machinery.

5. Versatility Modern automatic button sewers are designed to handle a wide range of button sizes and styles, making them versatile tools in the garment manufacturing industry. This adaptability allows manufacturers to produce a diverse range of clothing items without the need for extensive machine changes or downtime.

The Future of Button Sewing Technology

As technology continues to advance, the future of automatic button sewers looks promising. Innovations such as artificial intelligence and machine learning could further enhance these machines’ capabilities, allowing for real-time adjustments based on fabric types and button specifications. Additionally, the integration of internet connectivity will enable remote monitoring and maintenance, ensuring that production lines run smoothly with minimal interruptions.

Moreover, sustainability remains a key focus in the textile industry. The efficiency gains from automatic button sewers contribute to reduced energy consumption and waste, aligning with the growing demand for eco-friendly manufacturing practices. As consumers become more conscious of their purchasing choices, manufacturers are increasingly looking for ways to incorporate sustainable technologies into their production processes.

Conclusion

The automatic button sewer stands as a testament to the power of automation in the textile industry. With its ability to increase efficiency, reduce costs, and improve product quality, it is no wonder that this technology is becoming indispensable in modern garment manufacturing. As advancements continue to emerge, the automatic button sewer will likely evolve further, leading to even greater innovations and improvements in the world of fashion. Embracing this technology not only benefits manufacturers but also paves the way for a more sustainable and efficient future in textile production.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025