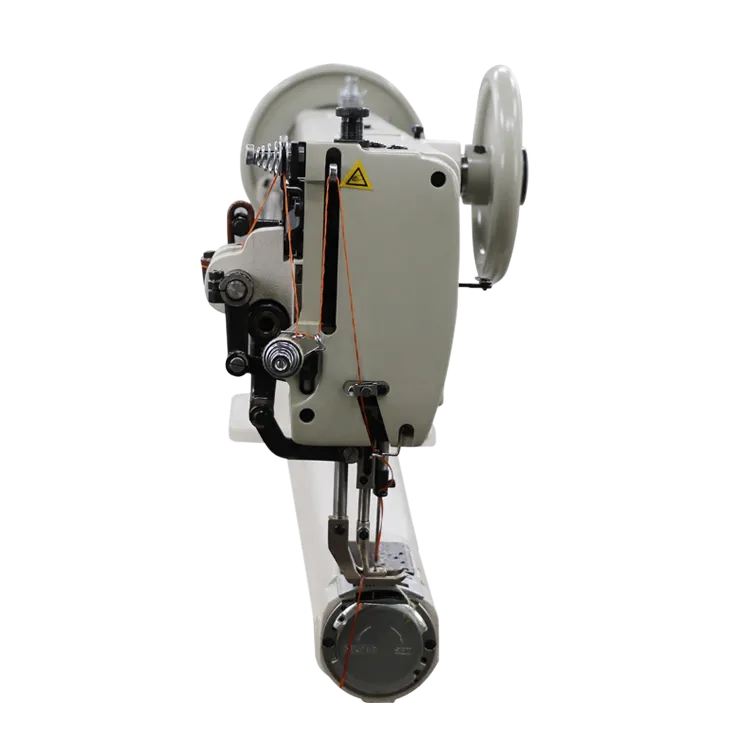

auto interior sewing machine

The Evolution of Auto Interior Sewing Machines

In the world of automotive manufacturing, the interior aesthetics and comfort are just as crucial as the performance of the vehicle. The art of creating beautiful and functional interiors has evolved significantly over the years, and at the heart of this evolution lies the auto interior sewing machine. These machines play a vital role in bringing the stylish and comfortable interiors of modern vehicles to life.

Auto interior sewing machines are specially designed to handle heavy fabrics, leather, and other materials commonly used in car upholstery. Unlike standard sewing machines, these industrial-grade machines are built to withstand the rigorous demands of automotive production. They feature strong motors, robust frames, and specialized attachments that allow for precise stitching on various materials, ensuring durability and an aesthetic finish.

Historically, auto interiors were crafted by skilled artisans who spent countless hours hand-stitching materials together. This labor-intensive process was not only time-consuming but also required a high level of skill. With the rise of mass production in the automotive industry, manufacturers sought ways to enhance efficiency without compromising quality. Enter the auto interior sewing machine a game-changing innovation that revolutionized the way car interiors are produced.

auto interior sewing machine

Modern auto interior sewing machines come equipped with advanced technology, such as computerized systems that enable precise stitching patterns and automatic tension adjustments. This technological advancement has greatly improved the consistency and speed of production, allowing manufacturers to meet the growing demand for customized interiors. Today, car enthusiasts can choose from a variety of materials, colors, and stitching styles, all made possible through the capabilities of these sophisticated machines.

Moreover, the automation of sewing processes not only elevates the quality of the finished product but also contributes to sustainability efforts within the automotive industry. With reduced waste and enhanced efficiency, manufacturers can optimize their resources while delivering high-quality interiors. This shift towards automation is also paving the way for new design possibilities, as manufacturers can experiment with innovative materials and complex designs that were previously challenging to achieve by hand.

In conclusion, auto interior sewing machines have transformed the automotive industry's approach to vehicle design and production. By marrying traditional craftsmanship with modern technology, they create superior interiors that enhance both the visual appeal and comfort of vehicles. As the industry continues to innovate, these machines will undoubtedly play a pivotal role in shaping the future of automotive interiors, ensuring that every journey is not just a drive but an experience.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025