Advanced Stitching Machines for Woven Sack Bags Ensuring Durability and Efficiency in Production.

The Role of Woven Sack Bag Stitching Machines in the Packaging Industry

In today's fast-paced manufacturing and packaging industry, efficiency and precision are paramount. One of the key players in this domain is the woven sack bag stitching machine. Designed specifically for stitching woven polypropylene or jute bags, these machines streamline the process of bag production, contributing significantly to both time and cost savings. As global demand for various packaged goods continues to rise, the importance of such machines in the packaging sector cannot be overstated.

Understanding the Woven Sack Bag

Woven sacks, also known as woven bags or fabric bags, are widely used for packing agricultural products, construction materials, and various consumer goods. These bags are made from woven polypropylene or other synthetic fibers, making them durable, water-resistant, and lightweight. The versatility of woven sacks has made them a preferred choice across industries, including agriculture, food processing, chemical, and retail.

The Function of Stitching Machines

Woven sack bag stitching machines are designed to efficiently sew the open ends of these woven sacks. By using either thread stitching or ultrasonic welding techniques, these machines secure the contents within the bags, thus ensuring their safe transportation and storage. The stitching process can significantly influence the strength and durability of the bags, which is critical given that they often carry heavy loads.

Types of Stitching Machines

There are various types of stitching machines available for woven sacks, and each serves specific needs. The most popular include

1. Single Needle Lockstitch Machines These are common for basic sewing tasks, providing a strong and secure stitch. They are particularly effective in high-speed production environments.

2. Double Needle Machines Ideal for producing bags with artistic patterns or double seams, enhancing both aesthetics and strength.

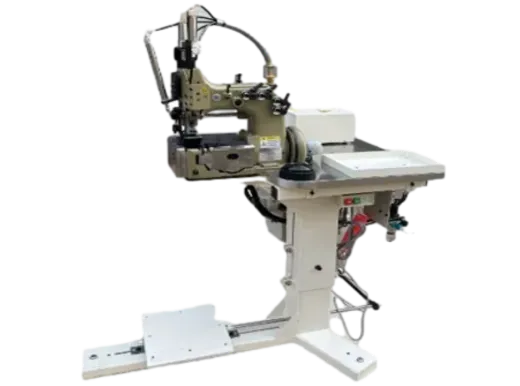

woven sack bag stitching machine

3. Ultrasonic Stitching Machines These use high-frequency ultrasonic waves to seal edges and create seams without the need for thread. This method not only speeds up production but also reduces the cost of materials.

4. Automatic Stitching Machines Fully automated systems offer advanced technological solutions, increasing production rates and minimizing human error.

Benefits of Woven Sack Bag Stitching Machines

Investing in woven sack bag stitching machines brings numerous advantages

- Increased Efficiency Automated machines allow for faster production rates, which is crucial in meeting the demands of a growing market.

- Cost-Effectiveness By reducing manual labor and material waste, these machines help businesses optimize their operational costs.

- Consistency and Quality High-quality stitching ensures that bags can withstand the rigors of transportation and handling, thus minimizing damage and product loss.

- Customization Options Advanced models offer the ability to create customized bags that cater to specific industry requirements or branding needs.

Conclusion

The woven sack bag stitching machine plays a vital role in the manufacturing process of woven bags, enhancing efficiency, reducing costs, and ensuring quality. As industries continue to evolve and the demand for sustainable packaging solutions increases, the importance of investing in advanced stitching technologies will only grow. Companies looking to enhance their productivity and maintain a competitive edge should consider incorporating these machines into their production lines. With their myriad benefits, woven sack bag stitching machines are not just tools; they are essential assets in the future of packaging.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025