Advanced Sewing Machines for Efficient Jumbo Bag Production and Increased Material Handling Capability

The Importance of Jumbo Bag Sewing Machinery in Modern Industries

In recent years, the demand for jumbo bags, also known as FIBC (Flexible Intermediate Bulk Containers), has skyrocketed across various industries, including agriculture, construction, and chemicals. These bags are designed to hold substantial quantities of materials, making them essential for efficient transport and storage. However, producing these bags requires specialized machinery, specifically jumbo bag sewing machinery. This article delves into the significance of this machinery, its working principles, and its impact on industrial operations.

What is Jumbo Bag Sewing Machinery?

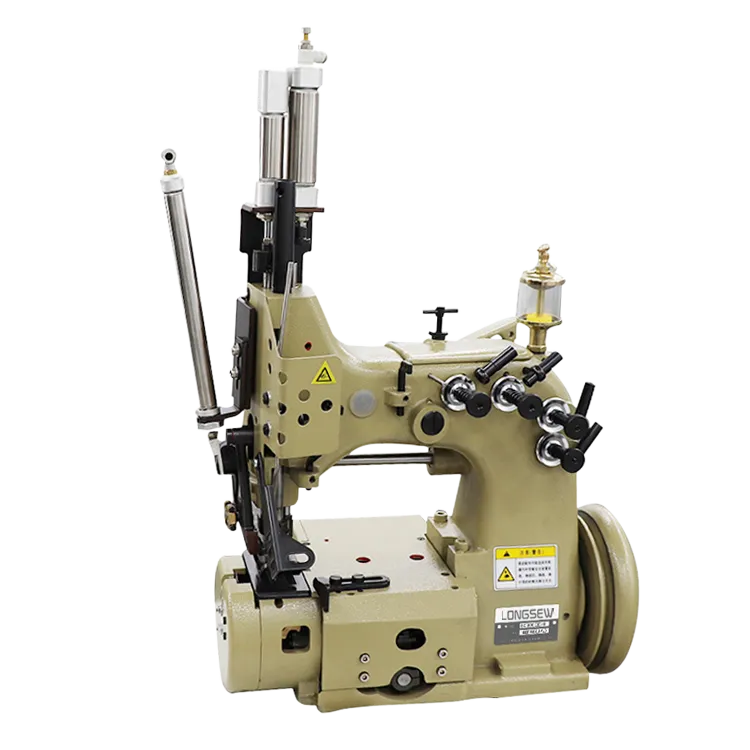

Jumbo bag sewing machinery refers to specialized industrial sewing machines used for stitching large bags made from woven polypropylene or similar fabrics. These machines are engineered to handle multiple layers of heavy-duty materials, ensuring that the seams are strong enough to withstand the weight and pressure exerted by the contents of the bags. With the versatility to sew various types of bags, such as open-top, closed-top, and vented jumbo bags, this machinery plays a crucial role in the production process.

Features of Jumbo Bag Sewing Machinery

Jumbo bag sewing machines come with several features that enhance their functionality and efficiency

1. Heavy-Duty Build Designed to handle thick materials, these machines are equipped with powerful motors and robust construction. This ensures durability and the ability to sew reliably under heavy conditions.

2. Multiple Stitch Patterns Many machines offer various stitching options, allowing manufacturers to choose the best type for specific applications. This flexibility is vital for producing bags suitable for different products, such as grains, sand, or chemical powders.

jumbo bag sewing machinery

3. Automated Functions Modern jumbo bag sewing machinery often incorporates automation, including automatic thread cutting, fabric feeding, and position alignment. This reduces labor costs and increases productivity.

4. Adjustable Parameters Users can modify settings such as stitch length and speed according to the materials being sewn and the specific bag design requirements.

The Impact on Production Efficiency

The introduction of jumbo bag sewing machinery has significantly transformed the production landscape for manufacturers. Firstly, it enhances productivity by enabling high-speed sewing, which means more bags can be produced in less time. This increased output is beneficial, especially in industries where time is a critical factor.

Secondly, the precision offered by these machines reduces material wastage, as accurate stitching prevents tears and defects. By minimizing errors in the production process, companies can save costs and improve their profit margins.

Moreover, the reliability and strength of the seams produced by jumbo bag sewing machines directly impact the safety and quality of the bags. Stronger seams lead to fewer failures during transportation or storage, thereby preserving the integrity of the products inside.

Conclusion

In conclusion, jumbo bag sewing machinery is a vital component of the manufacturing process for industries that rely on bulk packaging. Its advanced features, such as heavy-duty construction, automation, and customizable settings, enhance productivity, reduce costs, and ensure the quality of the final product. As the demand for jumbo bags continues to grow, investing in high-quality sewing machinery will remain crucial for manufacturers striving to meet industry standards and customer expectations. By embracing these technological advancements, businesses can stay competitive in a fast-paced global market.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025