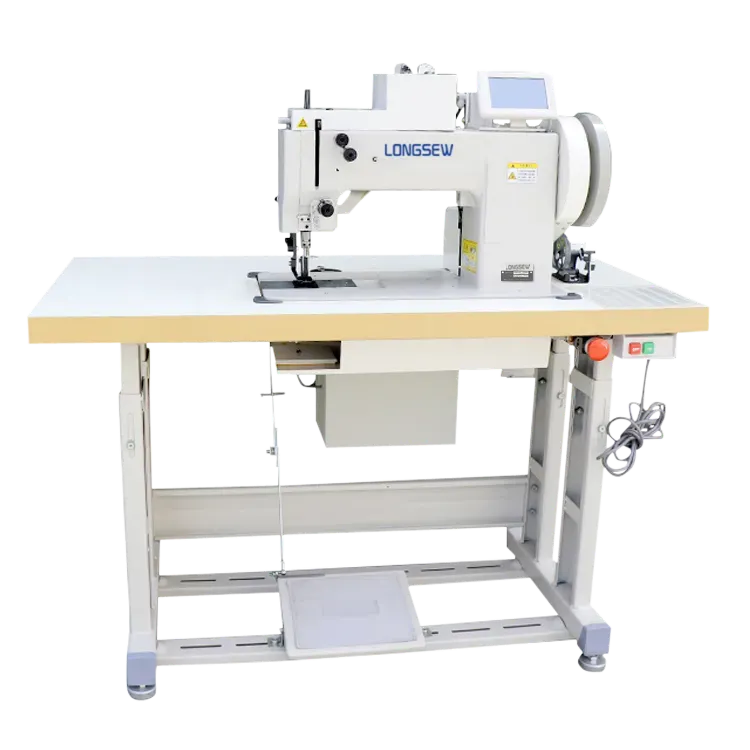

Advanced Industrial Zig Zag Machines for Efficient Textile Processing and Seamless Automation Solutions

Industrial Zig Zag Machine Revolutionizing Textile Production

In the ever-evolving landscape of textile manufacturing, the industrial zig zag machine has emerged as a crucial tool for enhancing efficiency and precision in fabric production. Designed to offer versatile stitching options, this machine is particularly favored in applications where durability and aesthetic appeal are essential. From garment making to home textiles, the zig zag machine provides an array of functionalities that cater to the diverse needs of the textile industry.

One of the primary advantages of the industrial zig zag machine is its ability to execute a wide variety of stitch patterns. Unlike traditional straight stitch machines, the zig zag configuration allows for more flexible designs, enabling manufacturers to produce intricate patterns that enhance the visual appeal of garments and other textile products. This flexibility is especially beneficial in the fashion industry, where unique and eye-catching designs can set a brand apart from its competitors.

Moreover, the zig zag stitch serves a critical role in fabric reinforcement. When working with stretchable or delicate materials such as knits and jerseys, the zig zag stitch provides the necessary elasticity to prevent seams from breaking during wear. This characteristic is vital in activewear production, where garments must withstand rigorous movements without compromising their structure. The ability to create strong, elastic seams not only prolongs the lifespan of the product but also ensures customer satisfaction, ultimately leading to increased brand loyalty.

In addition to fashion and activewear, the industrial zig zag machine finds applications across various other sectors, including automotive upholstery and home décor

. The machine's versatility enables manufacturers to address the specific requirements of different fabrics, from heavy-duty materials used in automotive interiors to lightweight textiles used in curtains and upholstery. As the demand for custom and specialized products continues to rise, the zig zag machine stands out as a solution that can accommodate varying fabric types and stitching requirements.industrial zig zag machine

Technological advancements have further elevated the capabilities of the industrial zig zag machine. Modern iterations are equipped with computerized systems that allow for precise control over stitch length, width, and pattern. This automation not only enhances accuracy but also speeds up the production process, which is vital in an industry often driven by tight deadlines. Additionally, user-friendly interfaces enable operators to easily adjust settings, minimizing downtime and maximizing productivity on the shop floor.

Sustainability is another significant consideration in today's textile industry. As consumers become increasingly aware of environmental issues, manufacturers are seeking ways to minimize waste and improve the efficiency of their production processes. The zig zag machine contributes to this goal by reducing fabric waste during cutting and sewing. Its ability to sew seams with less overlap ensures that materials are used more efficiently, thereby reducing the environmental footprint of textile production.

Training and skill development are essential for maximizing the potential of industrial zig zag machines. As the technology evolves, so too must the workforce that operates it. Providing training programs for operators not only enhances their technical skills but also improves overall operational efficiency. By investing in skilled personnel, companies can fully leverage the benefits of these advanced machines, paving the way for innovation and growth within the textile sector.

In conclusion, the industrial zig zag machine plays a pivotal role in modern textile manufacturing. Its versatility, durability, and technological advancements allow manufacturers to meet the ever-changing demands of the market while maintaining high-quality standards. As the industry continues to evolve, the significance of the zig zag machine will undoubtedly grow, making it an essential tool for any textile manufacturer seeking to remain competitive in today’s dynamic environment.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025