Advanced Computerized Sewing Machines for FIBC Bag Production and Customization Solutions

The Role of Computerized Sewing Machines in FIBC Bag Production

In the world of industrial textiles, the production of Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, has become increasingly sophisticated. As businesses strive for efficiency and quality, technology plays a pivotal role in transforming traditional manufacturing processes. Among the most significant advancements in this field is the adoption of computerized sewing machines.

FIBC bags are designed to carry and transport large quantities of materials, making them vital in various industries such as agriculture, mining, construction, and chemicals. The construction of these bags requires precision and durability, necessitating the use of advanced sewing technology. Computerized sewing machines have emerged as a game changer, offering numerous advantages over their conventional counterparts.

The Role of Computerized Sewing Machines in FIBC Bag Production

Moreover, computerized sewing machines are equipped with advanced software that allows for intricate design and customization. This capability is crucial for FIBC production, as clients often require specific sizes, shapes, and printed logos to meet their branding needs. With computerized systems, manufacturers can easily modify designs and automate complex sewing patterns, ensuring that each bag meets the required specifications. This flexibility not only improves customer satisfaction but also supports manufacturers in conveying their brand identity through customized packaging solutions.

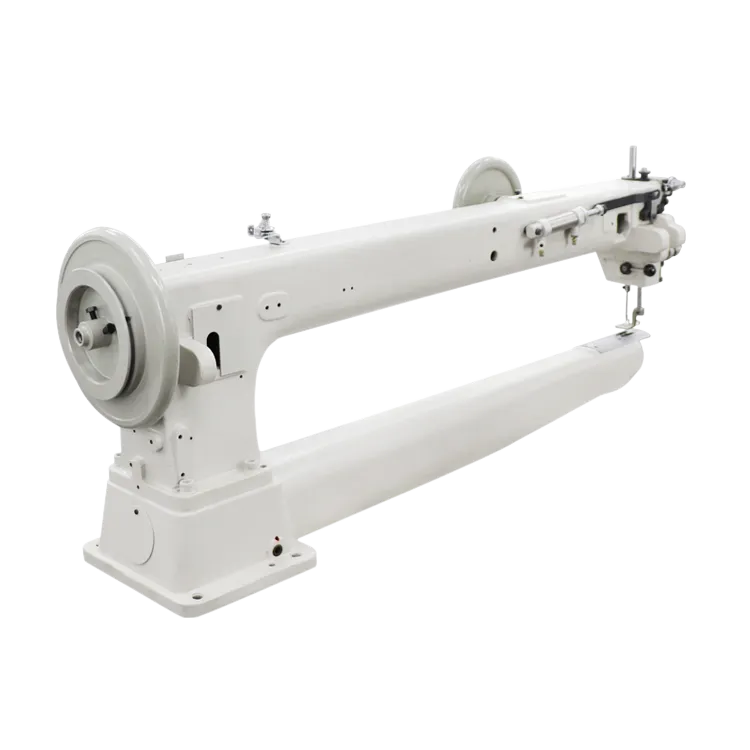

fibc bag computerized sewing machine

Precision is another significant advantage offered by computerized sewing machines. Traditional sewing methods often rely heavily on manual labor, which can lead to inconsistencies and errors. With computerized technology, the sewing process is meticulously controlled, reducing the likelihood of defects. High precision in stitching is essential for FIBC bags, as any weakness in the seams can compromise the bag's strength and safety when transporting heavy loads. Consequently, computerized machines play a critical role in enhancing the reliability of these bags.

Furthermore, computerized sewing machines are often designed to be user-friendly, featuring touchscreens and intuitive interfaces. This ease of operation enables workers to quickly learn how to use the machines, reducing training times and increasing overall workforce efficiency. With features such as automated threading and tension adjustments, operators can focus on monitoring the production process rather than dealing with technical issues, which enhances workflow and minimizes downtime.

In terms of sustainability, the implementation of computerized sewing machines can also lead to significant material savings. Precise cutting and stitching reduce fabric waste during the production of FIBC bags. As sustainability becomes an increasingly important factor for consumers and businesses alike, adopting technology that minimizes waste not only supports environmental goals but also improves profit margins for manufacturers.

In conclusion, the integration of computerized sewing machines in the production of FIBC bags represents a significant advancement in the industry. By enhancing productivity, ensuring precision, allowing customization, and promoting sustainability, these machines are revolutionizing how bulk bags are manufactured. As the demand for FIBC bags continues to grow across various sectors, the role of advanced sewing technology will likely become even more critical, driving efficiency and innovation in an ever-evolving marketplace.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025