A Comprehensive Guide to Choosing the Best Sewing Machines for Leather Crafting and Upholstery

The Essentials of Sewing Machines for Leatherwork

Sewing machines have long been an essential tool for crafting garments, upholstery, and a host of other fabric-based projects. However, for artisans who focus on leatherwork, the choice of sewing machine becomes a crucial factor in ensuring quality and efficiency. Leather, with its unique properties, demands specific features in a sewing machine, making it imperative for crafters to select the right equipment.

Understanding Leather as a Material

Leather is a durable and versatile material that presents specific challenges when it comes to sewing. Unlike typical fabrics, leather does not have a grain that can easily fray, but it is thick and stiff, which can complicate the sewing process. It also requires heavier threads and needles capable of piercing its tough surface. Therefore, using a sewing machine that is designed specifically for leather can vastly improve the quality of your work and the speed of your projects.

Key Features to Look For

When searching for a sewing machine capable of handling leather, there are several essential features to consider

1. Heavy-Duty Construction A strong and sturdy build will support the pressure applied during sewing thick leather. Machines with metal frames are generally more durable and provide greater stability.

2. Walking Foot A walking foot mechanism is essential for sewing leather as it helps to move multiple layers of material evenly through the machine. This feature prevents any slipping or bunching that may occur with standard presser feet.

3. High Needle Capacity Leather is thicker than most fabrics, so a sewing machine with a high needle lifting capacity can accommodate various thicknesses efficiently. This feature allows users to switch between different leather types without hindrance.

4. Adjustable Speed Control Leatherwork often requires precision and meticulous stitching. A sewing machine with adjustable speed will allow users to slow down their sewing when handling intricate designs or corners.

5. Specialized Needles and Threads Ensure the machine is compatible with specially designed leather needles and heavier threads. The right needle and thread combination can drastically affect the final look and durability of the finished piece.

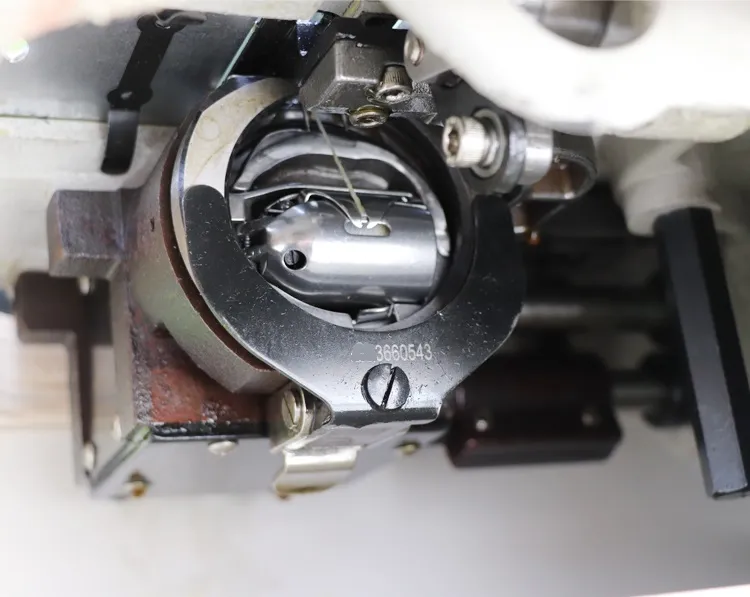

sewing machine that can sew leather

Popular Models

Some sewing machines have gained popularity within the leatherworking community due to their specific features and reliability. For example, the Sailrite Fabricator is highly regarded for its heavy-duty performance and versatility, making it ideal for leather goods. Similarly, the Juki TL-2010Q is another excellent option, known for its ease of use and ability to deliver high-quality stitches on various materials, including leather.

Tips for Sewing Leather

Beyond selecting the right machine, there are several tips to consider when sewing leather

1. Test Stitches on Scraps Always practice on scrap pieces of leather before starting on your actual project. This allows you to adjust tension, stitch length, and other settings.

2. Use the Right Thread Polyester or nylon threads are usually recommended for leather projects because they provide strength and durability.

3. Avoid Pinning Instead of using pins, consider using clips to hold layers together. Pins can leave holes in the leather and alter its appearance.

4. Maintain Your Machine Regular maintenance of your sewing machine is crucial, especially when working with tough materials like leather. Keep it clean and ensure that the needle is changed regularly to maintain quality stitching.

Conclusion

Investing in a sewing machine that can handle leather is pivotal for anyone interested in leather crafting. With the right tools and techniques, artisans can bring their creative visions to life while ensuring that their projects are both beautiful and durable. Whether you’re a hobbyist or a professional, understanding the unique demands of leather sewing will help you achieve exceptional results.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025