High-Performance 2% Needle Chain Stitch Machines for Superior Sewing Quality and Efficiency

Understanding the 2% Needle Chain Stitch Machine A Comprehensive Overview

In the world of textile manufacturing and garment production, various sewing machines play crucial roles in determining the quality, efficiency, and versatility of the final products. Among these, the 2% needle chain stitch machine has carved out a niche for itself, offering unique advantages and capabilities that make it indispensable for certain applications.

What is a 2% Needle Chain Stitch Machine?

The 2% needle chain stitch machine is primarily characterized by its specific stitch formation, which utilizes two needles to create a chain stitch. This distinctive stitching technique is known for its strength and elasticity, making it ideal for a variety of fabrics, especially stretchable materials. The term 2% refers to the machine’s design, which often emphasizes this dual needle configuration, allowing for higher productivity rates and enhanced stitch quality.

Features and Components

The machine is equipped with a variety of features that contribute to its effectiveness. Key components include

1. Dual Needles The two needles work in tandem to produce a more robust seam. This structure not only increases the durability of the stitches but also provides a unique aesthetic finish to the garments.

2. Feed Mechanism A reliable feed mechanism ensures consistent fabric movement through the machine, allowing for smooth and precise stitching. This is particularly important when working with slippery or lightweight materials.

3. Adjustable Stitch Length The ability to modify stitch length provides versatility. This feature allows manufacturers to produce stitches that are tailored to specific garment requirements, whether for casual wear or more formal attire.

4. Thread Tension Control Precise thread tension is vital in chain stitching. The machine's built-in tension controls help to ensure that the stitches remain uniform and do not pucker or become loose during the sewing process.

5. Speed Settings Many 2% needle chain stitch machines offer adjustable speed settings, facilitating high-speed sewing while maintaining stitch quality. This is essential for high-volume production environments where efficiency is key.

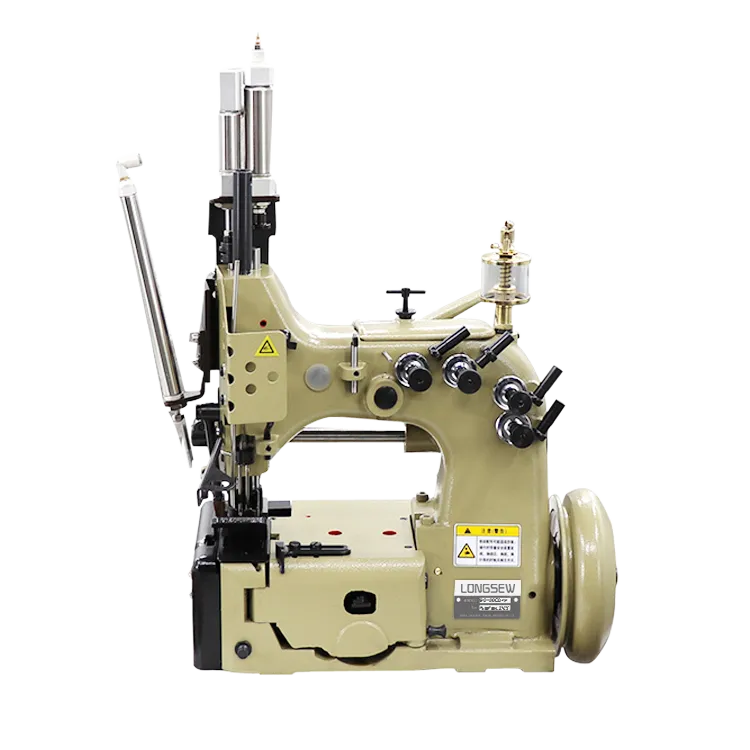

2 needle chain stitch machine

Applications

The 2% needle chain stitch machine is commonly used in various sectors of garment manufacturing. Its prominent applications include

- Activewear Production The ability to create strong yet flexible seams makes it ideal for activewear, where comfort and stretchability are crucial. - Denim and Heavy Fabrics This machine excels at sewing heavier materials like denim, creating robust seams that can withstand wear and tear. - Specialized Fabrics It is also utilized for specialized textiles, including those that require additional stretch or movement, such as swimwear and sports apparel.

Advantages

The adoption of the 2% needle chain stitch machine presents numerous advantages

1. Durability The chain stitch created by dual needles is known for its strength, resulting in seams that can withstand significant stress without ripping.

2. Elasticity With its design, this machine produces seams that maintain elasticity and flexibility, crucial for modern garment production.

3. Reduced Production Time The machine's efficiency and speed settings contribute to faster production cycles, benefitting manufacturers aiming to meet high demand.

4. Versatility Its ability to handle a wide range of fabrics makes it a versatile choice for many manufacturers, able to adjust for various types of garments.

Conclusion

The 2% needle chain stitch machine represents a significant advancement in sewing technology, merging precision with efficiency. Its unique features make it particularly suited for modern textile applications, catering to the ever-evolving needs of the fashion and garment industry. By understanding its capabilities and advantages, manufacturers can optimize their production processes, ensuring the delivery of high-quality products to the market. As the industry continues to advance, the role of specialized machines like the 2% needle chain stitch machine will undoubtedly grow, enhancing the art of garment creation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025