Jan . 10, 2025 08:16

Back to list

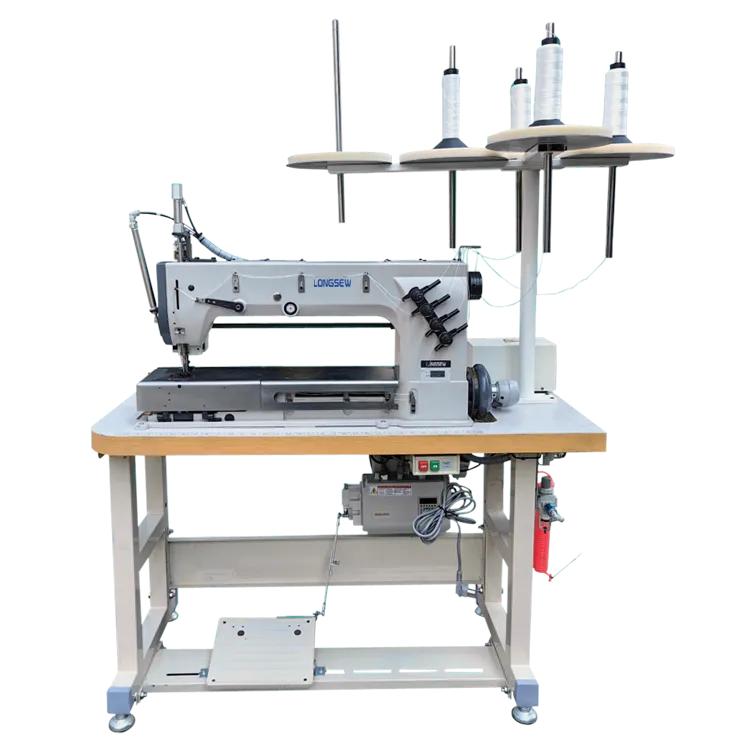

2 needle chain stitch

Understanding the intricacies of the 2-needle chain stitch is crucial for textile industry professionals and enthusiasts striving for precision in their creations. This specialized stitch is a staple among garment manufacturers, offering both aesthetic appeal and functionality.

Specialized sewing machinery has advanced to meet the demands of 2-needle chain stitching. Leading manufacturers offer machines equipped with programmable features that can monitor and adjust tension, thread supply, and needle positioning. Investing in such technology promises superior stitching outcomes, lower maintenance costs, and an increase in production efficiency. Professional training on these machines further underscores the commitment to crafting quality garments, ensuring operators are well-versed in the nuances of the 2-needle configuration. Quality assurance cannot be overstated when using a 2-needle chain stitch. Routine inspections and stringent testing protocols must be established to continually assess seam strength and elasticity across different fabric types. These measures corroborate a brand’s credibility and assertiveness in delivering the highest standards of fashion craftsmanship. Employing folks with extensive expertise in fabric handling and stitch engineering fosters an environment of excellence and innovation. Moreover, with environmental concerns at the forefront, the 2-needle chain stitch supports sustainable practices within the industry. The use of this stitch reduces waste by minimizing fabric distortion during production, thus optimizing material utilization. Brands focusing on sustainability can leverage this benefit to align with eco-friendly initiatives, appealing to an increasingly conscious consumer base. For those passionate about crafting impeccable fashion items, a profound understanding of the 2-needle chain stitch is indispensable. By adopting this technique, businesses not only enhance the overall quality of their output but also strengthen their position as leaders in the ever-evolving textile industry.

Specialized sewing machinery has advanced to meet the demands of 2-needle chain stitching. Leading manufacturers offer machines equipped with programmable features that can monitor and adjust tension, thread supply, and needle positioning. Investing in such technology promises superior stitching outcomes, lower maintenance costs, and an increase in production efficiency. Professional training on these machines further underscores the commitment to crafting quality garments, ensuring operators are well-versed in the nuances of the 2-needle configuration. Quality assurance cannot be overstated when using a 2-needle chain stitch. Routine inspections and stringent testing protocols must be established to continually assess seam strength and elasticity across different fabric types. These measures corroborate a brand’s credibility and assertiveness in delivering the highest standards of fashion craftsmanship. Employing folks with extensive expertise in fabric handling and stitch engineering fosters an environment of excellence and innovation. Moreover, with environmental concerns at the forefront, the 2-needle chain stitch supports sustainable practices within the industry. The use of this stitch reduces waste by minimizing fabric distortion during production, thus optimizing material utilization. Brands focusing on sustainability can leverage this benefit to align with eco-friendly initiatives, appealing to an increasingly conscious consumer base. For those passionate about crafting impeccable fashion items, a profound understanding of the 2-needle chain stitch is indispensable. By adopting this technique, businesses not only enhance the overall quality of their output but also strengthen their position as leaders in the ever-evolving textile industry.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025