Upholstery Stitching Machine - Precision Craftsmanship for Quality Upholstery

Upholstery stitching machines play a crucial role in the furniture and automotive industries, providing the necessary tools for creating durable and aesthetically appealing products. These specialized machines are designed to handle various types of materials, including leather, fabric, and vinyl, enabling manufacturers to produce upholstery that meets diverse consumer needs and preferences.

One of the primary advantages of upholstery stitching machines is their ability to deliver consistent and high-quality stitching. Unlike manual sewing, which can vary greatly depending on the operator's skill, these machines are engineered to maintain precision in every stitch. This consistency not only enhances the overall appearance of the upholstery but also improves the durability of the seams, ensuring that the finished product can withstand everyday wear and tear.

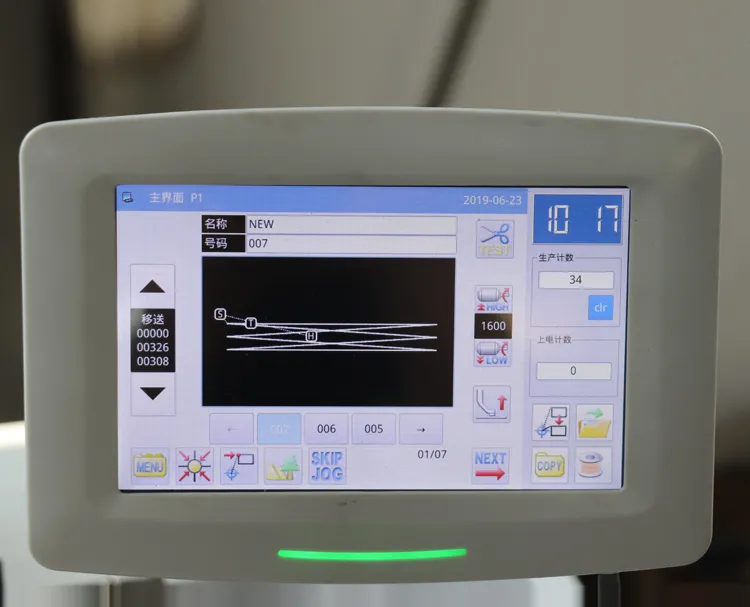

Modern upholstery stitching machines come equipped with advanced features that streamline the manufacturing process. Many models include programmable options that allow users to create custom stitching patterns, making it easier to produce unique designs. Additionally, some machines offer automatic thread cutting, which reduces downtime and increases efficiency during production runs.

Furthermore, these machines often incorporate user-friendly interfaces, making it easier for operators to adjust settings and monitor the stitching process. This ease of use is crucial in high-volume production environments, where efficiency and speed are paramount. Manufacturers who invest in reliable upholstery stitching machines can significantly increase their productivity and meet the growing demand for high-quality upholstered goods.

upholstery stitching machine

In terms of maintenance, it is essential to regularly service upholstery stitching machines to ensure their longevity and optimal performance. Routine checks and lubrication can prevent issues that could lead to costly repairs or production delays. A well-maintained machine not only boosts productivity but also enhances the overall quality of the upholstery produced.

As the upholstery market continues to evolve, the demand for innovative stitching solutions will grow. Manufacturers must stay abreast of technological advancements in stitching machinery to remain competitive. Embracing new technologies, such as computerized stitching and automation, can provide businesses with a significant edge in a crowded marketplace.

In conclusion, upholstery stitching machines are indispensable tools in the production of high-quality upholstered goods. Their precision, consistency, and efficiency not only improve product quality but also enable manufacturers to meet the ever-changing demands of consumers. With the right investments and maintenance practices, businesses can ensure that their upholstery stitching machines remain a vital asset in their production process.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025