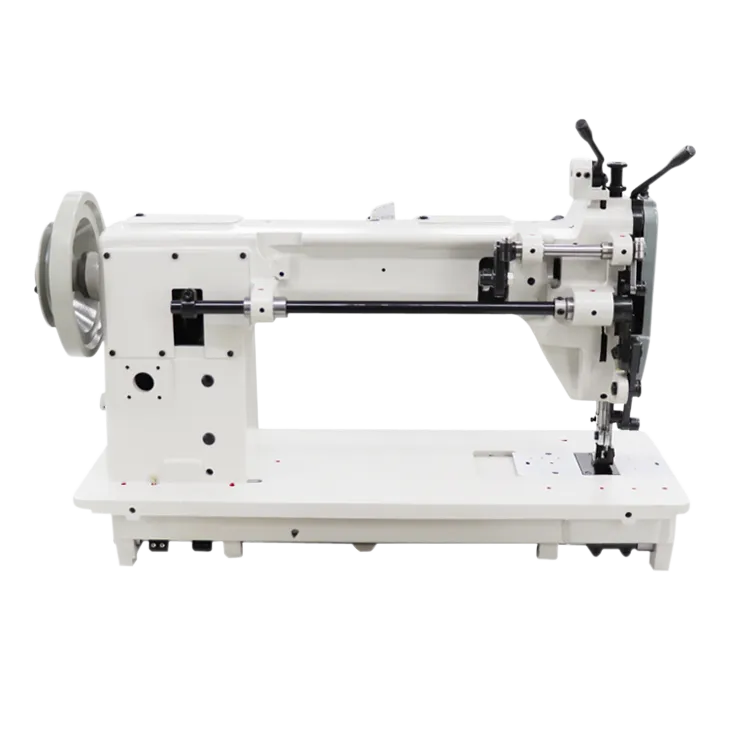

two needle industrial sewing machine

In the bustling world of industrial manufacturing, the two needle industrial sewing machine stands out as a staple of precision and efficiency. Favored by skilled professionals globally, this robust equipment caters to a variety of sewing tasks that demand high-speed and intricate detailing. The value of such machinery in a production line cannot be understated; it is instrumental in producing consistent quality outputs across numerous applications, ranging from automotive interiors to garment manufacturing.

A two needle industrial sewing machine is designed to streamline the sewing process by using two parallel needles. This mechanism is particularly beneficial when dealing with applications that require double stitching to enhance seam durability and aesthetic appeal. Unlike traditional single-needle machines, two needle machines can significantly reduce production time while ensuring superior strength in the seams. A critical advantage of using these machines is their ability to handle heavy-duty materials. Think of thick layers of denim, leather, or even synthetic composites—materials that are notoriously challenging for conventional sewing machines. The smooth operation of a two needle machine on such fabrics is backed by its powerful motor, sophisticated feeding system, and sturdy build. This ensures not only consistent stitch length but also prevents common issues like skipped stitches or needle breakage.

From a professional standpoint, the two needle sewing machine elevates both the quality and efficiency of production. For instance, in the automotive sector, the uniformity and strength of stitches for car seats or door panels are non-negotiable. The machine's capacity to produce identical parallel lines of stitching enhances both the aesthetic and practical aspects of the product, delivering excellence in seam integrity and appearance.two needle industrial sewing machine

Moreover, expert craftsmen and seamstresses find these machines indispensable for producing high-fashion garments. The ability of the two needle system to execute decorative stitching is invaluable in creating seams that are not only functional but also visually appealing. Tailors and designers can bring their visions to life, adding detailed embellishments and reinforcements that single needle machines cannot achieve as effectively.

Trust in these machines is reinforced through their reputation in the industry. Leading brands craft them with precision engineering, ensuring each unit is built to withstand heavy industrial use while maintaining accuracy. With minimal maintenance required, they offer a robust solution for high-volume manufacturing environments. Their reliability is evidenced by the seamless operation over prolonged use, a critical factor for any business seeking to minimize downtime and maximize productivity.

Operators appreciate the intuitive design that newer models offer, often featuring user-friendly interfaces to adjust settings. Innovations such as programmable stitch patterns and automatic threading enhance operational ease, making these machines more accessible to users at all skill levels.

Investing in a two needle industrial sewing machine is more than a purchase; it's an investment in quality and productivity. Companies leveraging these machines can expect not only an increase in output but also a significant improvement in product consistency and durability. This machinery is not merely a tool but a cornerstone of sewing efficiency and precision, embodying the epitome of engineering excellence and practical utility in industrial settings.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025