Understanding the Importance of Stitching Machine Needles in Textile Production

The Essential Role of Stitching Machine Needles in the Textile Industry

In the realm of textile manufacturing, stitching machine needles play a pivotal role in determining the quality, efficiency, and overall success of the production process. As the backbone of sewing technology, these seemingly simple components are crucial for a wide range of fabric applications, from garments to upholstery. Understanding the various types and purposes of stitching machine needles is essential for anyone involved in the textile industry.

Stitching machine needles come in a variety of shapes, sizes, and designs, each tailored to suit specific fabric types and sewing techniques. The most common types include universal needles, ballpoint needles, and jeans needles. Universal needles are versatile and can be used for woven and knit fabrics alike, while ballpoint needles feature a rounded tip designed to glide between fibers without damaging them, making them ideal for knit fabrics. Jeans needles, on the other hand, are specially designed with a thicker shaft and a strong point to penetrate through heavy fabrics such as denim.

The correct selection of a stitching machine needle is paramount for achieving high-quality seams. Using the wrong needle can lead to a myriad of issues, including skipped stitches, thread breakage, and fabric damage. For instance, if a standard needle is used on heavy fabrics, it may bend or break, causing delays in production and potentially ruining the material. Therefore, textile manufacturers must have a thorough understanding of their fabric types and production requirements to ensure they choose the appropriate needle.

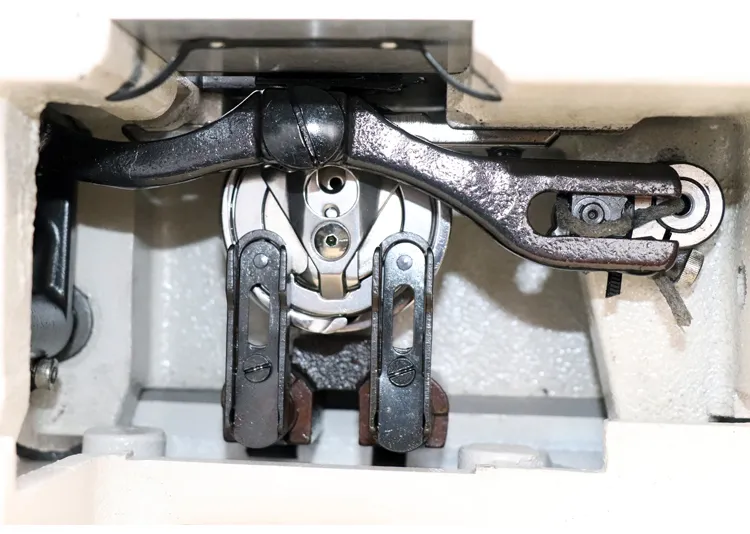

stitching machine needle

In addition to fabric compatibility, the size of the needle is another critical factor. Needle sizes are categorized by a numerical system, with larger numbers indicating a thicker needle. For example, a size 16 needle is suitable for heavier fabrics, while a size 10 needle is better for lightweight materials. Selecting the right size is crucial not only for causing minimal damage to the fabric but also for ensuring correct tension and stitch formation.

Beyond the basic functionality of stitching machine needles lies the importance of regular maintenance and replacement. Over time, needles become dull or damaged, which can lead to compromised stitching quality. Regularly changing needles is vital to maintain production standards and avoid costly errors. Industry experts recommend changing the needle after every project or after every eight hours of use, depending on the thickness and type of the fabric being sewn.

Moreover, advancements in technology have led to the development of specialized needles designed for specific applications. For example, there are needles designed for embroidery, leatherwork, and even quilting. These innovations reflect the evolving demands of the textile industry and emphasize the importance of specialized tools in achieving optimal results.

In conclusion, stitching machine needles are not just functional components; they are integral to the efficiency and quality of textile production. Understanding the different types, sizes, and maintenance needs of needles allows manufacturers to optimize their sewing processes, thereby improving the final product's quality. As the textile industry continues to evolve, so too will the technology surrounding stitching machine needles, making them an ever-important topic in manufacturing discussions. By selecting the proper needle for each job, textile producers can ensure that they meet the high standards expected in today’s competitive market.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025