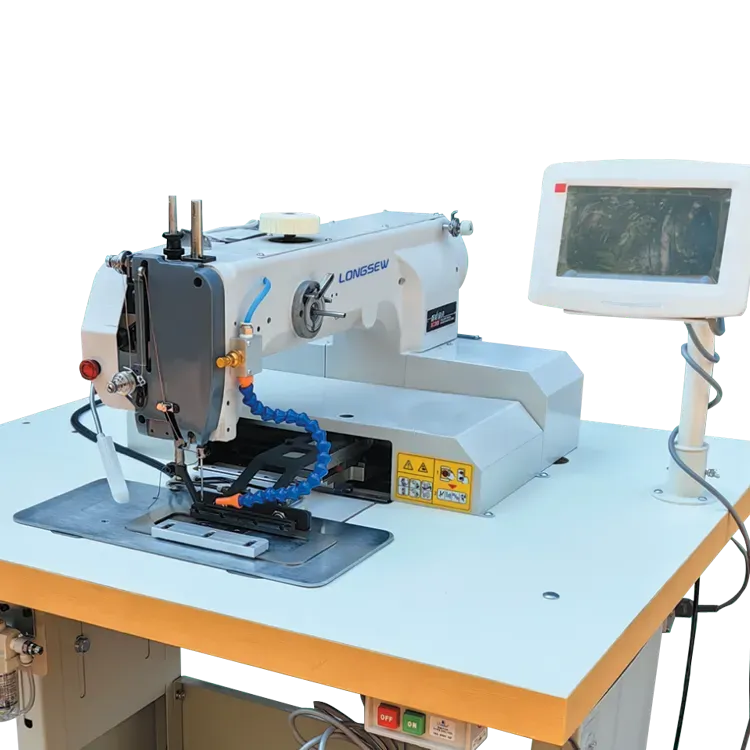

Machine for Crafting Long and High Arm Sails with Precision and Efficiency

The Long Arm and High Arm Sail Making Machine Revolutionizing Sail Production

In the world of marine craftsmanship, the production of sails has always been a unique blend of art and science. Sail makers have relied on both traditional techniques and modern technology to create sails that are not only functional but also aesthetically pleasing. One of the most significant advancements in sail manufacturing is the long arm and high arm sail making machine. This machine epitomizes the fusion of innovation and practicality, streamlining the sail-making process while enhancing the quality and durability of the final product.

The Need for Innovation in Sail Making

Historically, sail production involved manual labor that required significant skill and experience. Craftsmen carefully measured, cut, and stitched fabric by hand, a process that was both time-consuming and labor-intensive. By the early 20th century, the advent of industrial machinery began to change the landscape of many manufacturing sectors. However, the sail making industry lagged behind, as traditional methods were deeply rooted in the craft. The need for speed, precision, and increased production capacity led to the development of specialized machines, including the long arm and high arm sail making machine.

Features of the Long Arm and High Arm Sail Making Machine

The long arm and high arm sail making machine is designed to accommodate large sail panels that would be cumbersome to handle with standard sewing machines. The “long arm” feature allows for a wider reach, enabling the machine to sew larger pieces of fabric without difficulty. This is particularly beneficial when working with expansive sail designs or materials such as Dacron, which is commonly used for its durability and resistance to UV degradation.

The “high arm” aspect enhances the vertical space available for manipulating thick stacks of fabric, such as those used in multi-layered sails. This feature is crucial for ensuring that layers are stitched together accurately, providing the integrity and strength that sailors expect from their equipment. Additionally, these machines are equipped with powerful motors and advanced computer controls that facilitate precise stitching patterns and speeds, significantly reducing the time taken for production.

long arm and high arm sail making machine

Benefits of Using the Long Arm and High Arm Sail Making Machine

The benefits of adopting long arm and high arm sail making machines are manifold. First and foremost is the increase in efficiency. With the capacity to handle larger fabrics and multiple layers at once, these machines enable sail makers to produce sails in a fraction of the time it would take using traditional methods. This enhanced productivity translates to cost savings and the ability to meet market demands more effectively.

Moreover, these machines improve quality consistency. Advanced stitching technology ensures that each seam is uniform, reducing the likelihood of weak points that could compromise the sail’s performance. This is particularly important for competitive sailing, where even the smallest detail can affect a yacht’s performance.

Another significant advantage is the ergonomics of the operating experience. Sail making can be physically demanding, especially when manipulating large pieces of fabric. The long arm and high arm design reduces the strain on the operator, allowing them to work more comfortably and efficiently over extended periods.

The Future of Sail Making

As the maritime industry continues to evolve, so does the demand for innovative solutions that enhance performance and sustainability. The long arm and high arm sail making machine is set to play a pivotal role in this transformation. By integrating automation and smart manufacturing techniques, sail makers can optimize their workflows and reduce waste.

In conclusion, the long arm and high arm sail making machine represents a significant leap forward in the art of sail production. By combining efficiency, precision, and ergonomic design, it not only preserves the craftsmanship of traditional sail making but also propels it into a new era of technological advancement. As more sail makers adopt this innovative machinery, the nautical landscape will undoubtedly experience enhanced performance, safety, and sustainability, ensuring that the sails of tomorrow are crafted with the best tools available. The future of sail making is indeed bright, and the long arm and high arm machines are at the forefront of this exciting journey.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025