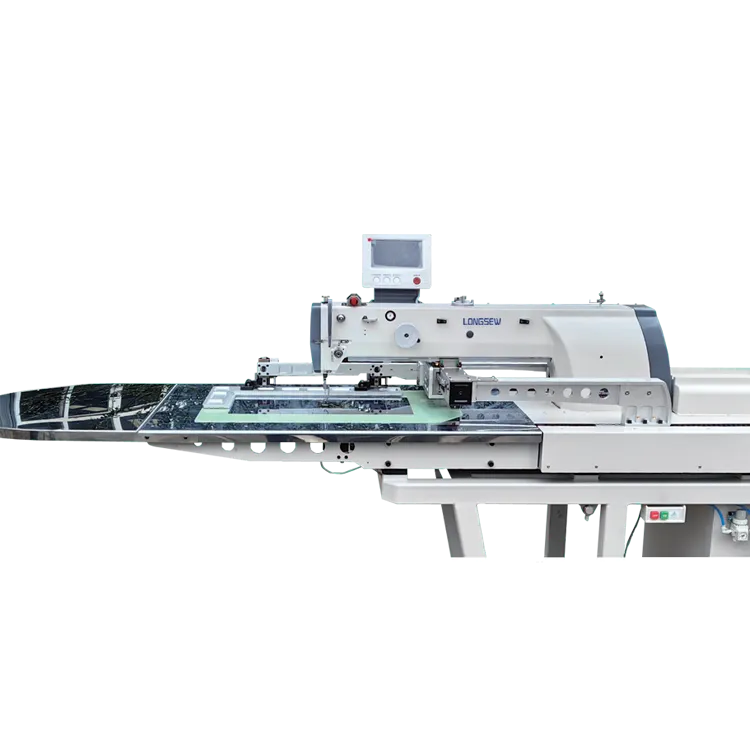

jumbo bag stitching machine

In the ever-evolving landscape of industrial packaging, the advent of the jumbo bag stitching machine marks a significant leap towards greater efficiency and reliability. For industries reliant on bulk material transfers, such as agriculture, construction, and manufacturing, these machines offer an invaluable solution, expertly designed to handle demanding packaging needs with precision.

The jumbo bag stitching machine exemplifies cutting-edge engineering, designed specifically for stitching heavy-duty FIBC (Flexible Intermediate Bulk Containers) bags, commonly referred to as jumbo bags. These machines are a testament to advanced manufacturing technology, incorporating features that cater to both speed and accuracy. Their robust construction ensures longevity and minimal downtime, essential for businesses reliant on continuous operation.

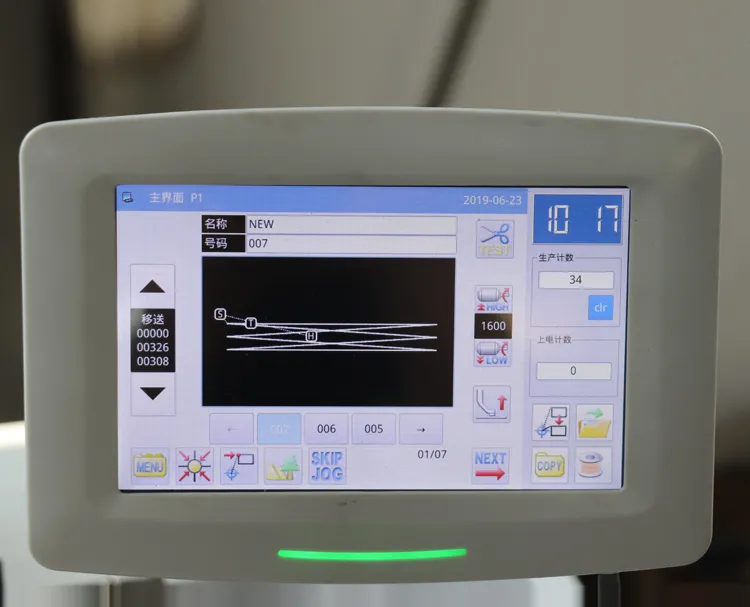

From a user's perspective, the experience of operating a jumbo bag stitching machine is markedly transformative. Operators benefit from the intuitive interfaces that allow for minimal training and quick adaptation. The seamless integration of automated features such as thread break detectors and tension control systems underscores the machine's sophistication. This reduces manual oversight and improves throughput, directly impacting operational efficiency.

The expertise required in manufacturing these machines is substantial. Only seasoned manufacturers with a deep understanding of textile engineering and industrial automation can produce equipment that meets the rigorous demands of high-volume bag production. The precision stitching ensures that every seam is flawlessly executed, maintaining the structural integrity of the jumbo bags during their lifecycle. This technical sophistication reflects the industry's commitment to maintaining high safety and quality standards.

jumbo bag stitching machine

Regarding authoritativeness, leading manufacturers of jumbo bag stitching machines typically comply with international certification standards such as ISO and CE. These endorsements vouch for the machines' reliability and safety, providing customers with the assurance that they are investing in a product manufactured to the highest global standards. Additionally, manufacturers often engage in continuous R&D, integrating feedback from various industry sectors to refine machine performance.

Building trustworthiness within this domain goes beyond machine performance; it involves ongoing support and service. Renowned brands prioritize establishing a solid relationship with their clients by offering comprehensive after-sale services, including installation assistance, training, routine maintenance, and repair services. Such commitments not only fortify customer confidence but also ensure that the machines operate at peak performance over their lifespan.

In conclusion, the jumbo bag stitching machine stands as a paragon of industrial efficiency, crafted with meticulous expertise and upheld by authoritative certifications. Its design focuses on enhancing user experience, underscored by sophisticated automation and ease of use. By choosing a reputable provider, businesses not only equip themselves with a tool of excellence but also enter a partnership grounded in trust and unwavering support. With the increasing demand for personalized and efficient packaging solutions, the jumbo bag stitching machine undoubtedly paves the way for future advancements in industrial packaging technology.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025