Jan . 09, 2025 10:37

Back to list

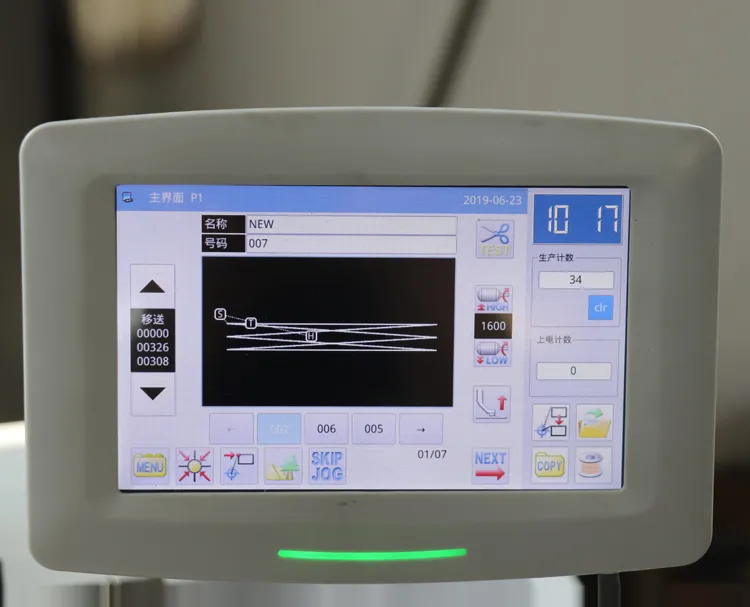

PP Woven Bag / Big Bag Single Needle 2 Threads Chainstitch Sewing Machine Head DN-2HS / DN-2LHS

Navigating the intricate world of jumbo bag sewing machines is a journey of both art and science where experience and expertise converge to transform raw materials into functional masterpieces. In the industrial packaging sector, jumbo bags, also known as FIBC (Flexible Intermediate Bulk Containers), are integral to transporting bulk goods safely and efficiently. The linchpin to their impeccable production is the sewing machine designed meticulously for these jumbo bags.

Trustworthiness in selecting the right jumbo bag sewing machine is reinforced through customer testimonials and industry accreditations. Companies with a proven track record of supporting clients with comprehensive after-sales service, including maintenance training and prompt technical support, earn trust in a competitive market. Machines that are certified by international quality standards bodies (such as ISO or CE) further assure buyers of their reliability and compliance with global safety and efficiency benchmarks. Choosing a jumbo bag sewing machine is more than a purchase; it is an investment in manufacturing reliability and productivity. Forward-thinking businesses understand the importance of aligning their needs with the technological capabilities of the machines. Engaging with industry forums, attending trade shows, and consulting with seasoned professionals can provide invaluable insights into the latest advancements and best practices in machine operation and maintenance. Ultimately, the decision to invest in a particular jumbo bag sewing machine should be informed by a balance of experience, expertise, authoritativeness, and trustworthiness. By prioritizing these aspects, companies are well-positioned to not only meet the current demands of their production lines but also embrace future opportunities in the ever-evolving arena of industrial packaging solutions.

Trustworthiness in selecting the right jumbo bag sewing machine is reinforced through customer testimonials and industry accreditations. Companies with a proven track record of supporting clients with comprehensive after-sales service, including maintenance training and prompt technical support, earn trust in a competitive market. Machines that are certified by international quality standards bodies (such as ISO or CE) further assure buyers of their reliability and compliance with global safety and efficiency benchmarks. Choosing a jumbo bag sewing machine is more than a purchase; it is an investment in manufacturing reliability and productivity. Forward-thinking businesses understand the importance of aligning their needs with the technological capabilities of the machines. Engaging with industry forums, attending trade shows, and consulting with seasoned professionals can provide invaluable insights into the latest advancements and best practices in machine operation and maintenance. Ultimately, the decision to invest in a particular jumbo bag sewing machine should be informed by a balance of experience, expertise, authoritativeness, and trustworthiness. By prioritizing these aspects, companies are well-positioned to not only meet the current demands of their production lines but also embrace future opportunities in the ever-evolving arena of industrial packaging solutions.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025