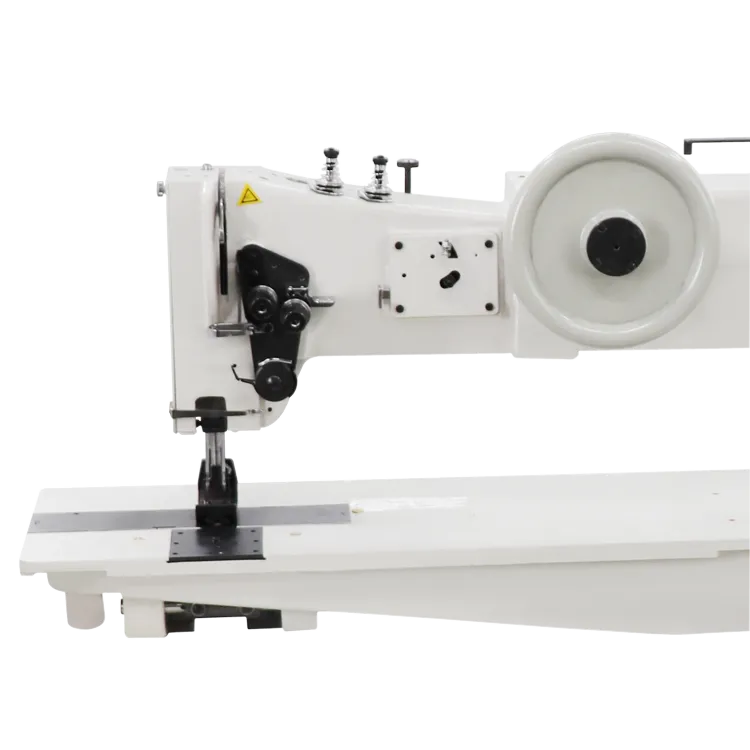

industrial walking foot machine

The Industrial Walking Foot Machine A Revolution in Sewing Technology

In the realm of textile and garment manufacturing, efficiency and precision are paramount. One of the remarkable innovations that have significantly enhanced these parameters is the industrial walking foot machine. This sewing machine stands out for its ability to handle heavy and thick materials, making it the go-to choice for various industries, including leather crafting, upholstery, and heavy fabric sewing.

The walking foot mechanism is the heart of this machine’s unique functionality. Unlike standard sewing machines that rely solely on the feed dogs to move the fabric, the walking foot machine has an additional feed mechanism – the walking foot itself. This foot moves in conjunction with the needle, ensuring that both the top and bottom layers of fabric feed together. This synchronized movement prevents fabric slippage and misalignment, which are common challenges when sewing multiple layers or slippery materials. As a result, users can achieve a professional finish, particularly on challenging projects.

One of the key advantages of the industrial walking foot machine is its capability to handle various materials, from lightweight fabrics like silk to heavy-duty materials such as canvas and leather. This versatility opens up a world of possibilities for manufacturers and designers alike. Whether creating rugged outdoor gear, high-quality leather goods, or intricate quilts, this machine can deliver excellent results. It’s not uncommon to see walking foot machines in factories producing products ranging from bags and belts to tents and automotive upholstery.

industrial walking foot machine

Moreover, durability is a hallmark of the industrial walking foot machine. Constructed with robust components, these machines are designed to withstand the rigors of industrial use. They can run for long hours, maintaining consistent performance without compromising on quality. Many industrial models also offer features like adjustable stitch length, which further enhances their adaptability for different projects.

In recent years, technology has further augmented the capabilities of walking foot machines. Modern advancements enable features such as automatic thread cutting, digital stitch regulation, and programmable sewing patterns. These innovations streamline the sewing process, reduce labor costs, and increase production speed. As industries evolve, so too do the machines that support them, ensuring that professionals can keep up with consumer demands for efficiency and quality.

In conclusion, the industrial walking foot machine represents a significant leap forward in sewing technology. Its unique feeding mechanism, versatility across various materials, and durability make it an essential tool in many manufacturing processes. As the textile and garment industries continue to grow and adapt to new challenges, the walking foot machine stands ready to meet the demands of the market, empowering creators to bring their visions to life with precision and ease. For anyone involved in heavy-duty sewing tasks, investing in a walking foot machine is not just a choice; it is a necessity for achieving excellence in craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025