Feb . 15, 2025 15:42

Back to list

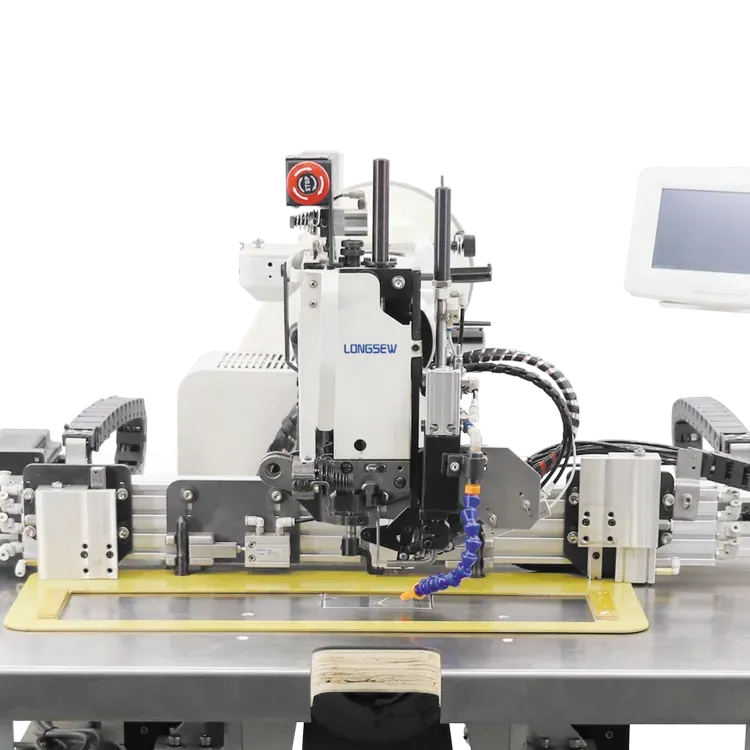

Heavy Duty Computerized Auto Pattern Sewing Machine For Safety Rope or Safety Belt LS273-2010H / LS273-2010S

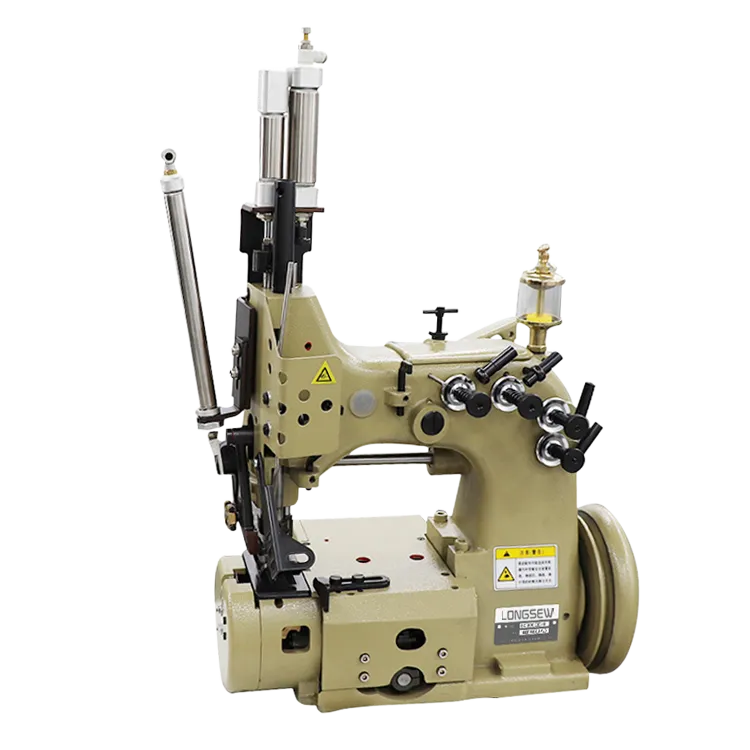

Industrial upholstery machines are the backbone of high-quality furniture and automotive interiors production. These robust machines are specifically designed to handle heavy fabrics, providing the precision and durability necessary for high-demand industrial applications. Their role in manufacturing cannot be understated; they ensure efficiency, precision, and quality in the finished products.

Additionally, the integration of advanced technology in new models has revolutionized the industry. Features like computerized controls allow for patterns and designs to be programmed directly into the machine. This capability helps manufacturers maintain consistency across products, a key element in maintaining brand reputation and customer satisfaction. Automated functions like thread trimming and tension control further simplify the sewing process, allowing operators to focus on more complex tasks. Attention to environmental impact is becoming increasingly important in industrial settings. Many of the leading upholstery machine manufacturers are now prioritizing sustainability in their designs. Machines that are energy-efficient and produce minimal waste are more appealing to environmentally-conscious manufacturers. As regulatory requirements around emissions and environmental protection grow stricter, adopting these machines can also help companies maintain compliance. Furthermore, sourcing parts and servicing machines is a critical aspect of ownership that cannot be overlooked. Choosing a brand that offers comprehensive support and easy availability of spare parts can prevent costly downtimes and ensure the longevity of the machine. Establishing a relationship with well-established suppliers can also afford insights into industry trends and future upgrades that might benefit your production line. Investing in an industrial upholstery machine is a significant decision that requires careful consideration of various factors, including cost, features, and post-purchase support. However, the right machine not only transforms your production capabilities but also positions your business for growth by enabling the delivery of superior quality products efficiently and reliably. In summary, when searching for a suitable industrial upholstery machine, understanding the features that align with specific production needs is paramount. With a focus on speed, versatility, durability, ease of operation, technological integration, and sustainability, businesses can enhance their production capabilities significantly. By leveraging these advanced machines, manufacturers ensure that they remain competitive in a demanding market, producing high-quality outcomes that meet the increasing expectations of quality and speed from consumers and business partners alike.

Additionally, the integration of advanced technology in new models has revolutionized the industry. Features like computerized controls allow for patterns and designs to be programmed directly into the machine. This capability helps manufacturers maintain consistency across products, a key element in maintaining brand reputation and customer satisfaction. Automated functions like thread trimming and tension control further simplify the sewing process, allowing operators to focus on more complex tasks. Attention to environmental impact is becoming increasingly important in industrial settings. Many of the leading upholstery machine manufacturers are now prioritizing sustainability in their designs. Machines that are energy-efficient and produce minimal waste are more appealing to environmentally-conscious manufacturers. As regulatory requirements around emissions and environmental protection grow stricter, adopting these machines can also help companies maintain compliance. Furthermore, sourcing parts and servicing machines is a critical aspect of ownership that cannot be overlooked. Choosing a brand that offers comprehensive support and easy availability of spare parts can prevent costly downtimes and ensure the longevity of the machine. Establishing a relationship with well-established suppliers can also afford insights into industry trends and future upgrades that might benefit your production line. Investing in an industrial upholstery machine is a significant decision that requires careful consideration of various factors, including cost, features, and post-purchase support. However, the right machine not only transforms your production capabilities but also positions your business for growth by enabling the delivery of superior quality products efficiently and reliably. In summary, when searching for a suitable industrial upholstery machine, understanding the features that align with specific production needs is paramount. With a focus on speed, versatility, durability, ease of operation, technological integration, and sustainability, businesses can enhance their production capabilities significantly. By leveraging these advanced machines, manufacturers ensure that they remain competitive in a demanding market, producing high-quality outcomes that meet the increasing expectations of quality and speed from consumers and business partners alike.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025