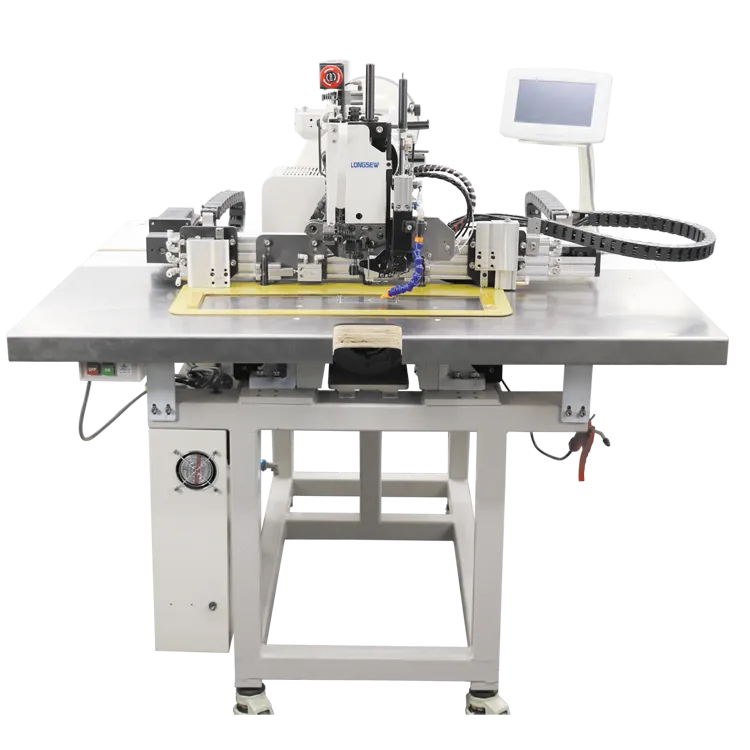

industrial flatbed sewing machine

The Rise of Industrial Flatbed Sewing Machines A Cornerstone of Modern Manufacturing

In the world of textile manufacturing, the industrial flatbed sewing machine stands as a pivotal tool that has transformed the way garments are produced. These machines are distinguished by their flatbed design, which provides a stable surface for large pieces of fabric, allowing for efficient and precise stitching. Over the years, the significance of flatbed sewing machines has only increased, fueled by advancements in technology and the ever-growing demands of the fashion industry.

At the heart of the industrial flatbed sewing machine's appeal is its versatility. These machines can handle a wide range of fabrics, from lightweight materials like silk to heavier textiles such as denim and canvas. This adaptability makes them ideal for manufacturers who produce various types of clothing, allowing them to switch between different projects without investing in multiple machines. This flexibility enhances productivity and reduces downtime, ultimately leading to cost savings for manufacturers.

One of the remarkable features of industrial flatbed sewing machines is their speed. Unlike standard home sewing machines, industrial variants are designed for high-speed operations, capable of sewing hundreds to thousands of stitches per minute. This speed is essential in a fast-paced manufacturing environment where meeting tight deadlines is crucial. With the ability to produce garments rapidly, companies can keep up with market demands while maintaining a competitive edge.

industrial flatbed sewing machine

Moreover, the durability of these machines contributes to their prominence in the industry. Built with robust materials and designed to withstand constant use, industrial flatbed sewing machines are engineered for longevity. This durability means that manufacturers can rely on these machines for extended periods, minimizing the need for frequent repairs or replacements. As a result, businesses can focus on scaling their operations without the distraction of equipment failures.

The integration of technology into industrial flatbed sewing machines has further revolutionized their functionality. Modern machines are equipped with computerized controls, automated functions, and advanced stitching options. These innovations not only enhance precision but also streamline the sewing process. Features like programmable stitch patterns and automatic thread cutting allow operators to produce high-quality garments with minimal human intervention. This technological shift also helps in training new operators, as many machines are user-friendly and come with digital interfaces.

As sustainability becomes increasingly important in the textile industry, industrial flatbed sewing machines are also evolving to meet these demands. Manufacturers are now adopting eco-friendly practices, such as using energy-efficient models and integrating recyclable materials into their production processes. This shift reflects a broader trend toward responsible manufacturing and better environmental stewardship.

In conclusion, the industrial flatbed sewing machine is an indispensable asset in modern textile manufacturing. Its versatility, speed, durability, and technological advancements make it a preferred choice for garment production. As the industry continues to evolve, these machines will undoubtedly play a crucial role in shaping the future of fashion, ensuring that manufacturers can adapt to changing trends while maintaining high standards of quality and efficiency. The reiteration of commitment to innovation and sustainability will further solidify the industrial flatbed sewing machine's status as a cornerstone of the manufacturing process.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025