Understanding the Benefits of Using Heavy Stitching Machines in Textile Production

The Heavy Stitching Machine A Game Changer in Textile Manufacturing

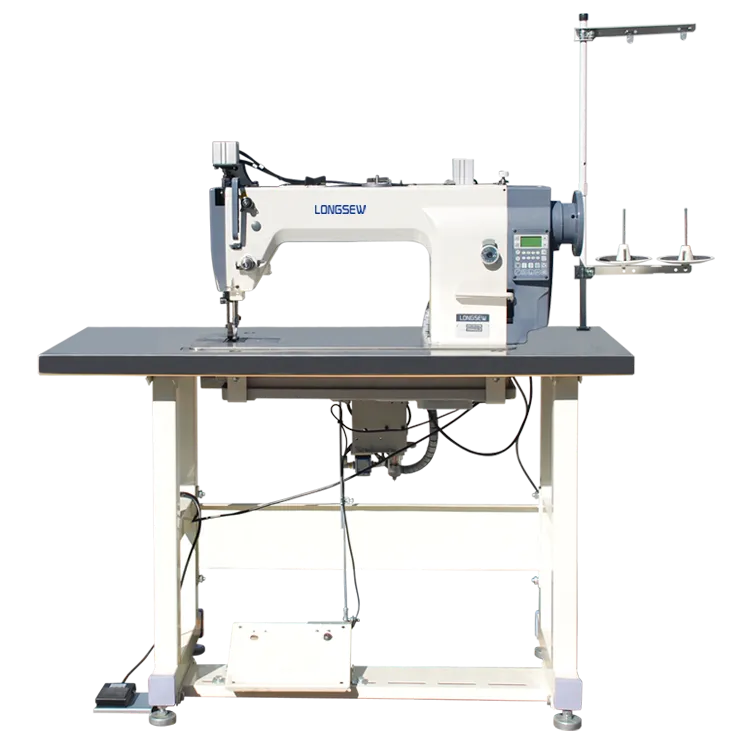

In the dynamic world of textile manufacturing, efficiency and precision are paramount. One of the most significant innovations that have revolutionized this industry is the heavy stitching machine. Designed to handle the robust demands of commercial and industrial sewing, these machines are essential tools for various applications, from clothing production to upholstery and heavy-duty textiles.

Understanding Heavy Stitching Machines

Heavy stitching machines are specifically engineered to work with thick fabrics and multiple layers of material. Unlike standard sewing machines, which may struggle with heavy-duty applications, these machines are equipped with powerful motors and reinforced components that can withstand the rigors of industrial sewing. They feature specialized needles, heavier threads, and robust feed systems that ensure smooth operation even when working with challenging materials such as denim, canvas, leather, and other thick textiles.

Applications Across Industries

The versatility of heavy stitching machines makes them invaluable across multiple industries. In the fashion industry, they are commonly used for creating durable outerwear, sportswear, and accessories. Upholstery businesses rely on these machines for crafting furniture covers, curtains, and cushions that require strong seams and reliable performance.

In the automotive industry, heavy stitching machines are employed to produce seat covers, airbags, and other components that must endure significant wear and tear

. Furthermore, in the field of outdoor gear manufacturing, these machines excel in producing tents, backpacks, and other gear that must withstand harsh weather conditions.heavy stitching machine

Benefits of Heavy Stitching Machines

The benefits of utilizing heavy stitching machines are manifold. First, they enhance productivity by allowing manufacturers to complete projects more quickly, which is essential in a fast-paced market. The reliability of these machines means less downtime for repairs, translating to cost savings and increased output.

Moreover, the quality of stitching that heavy machines provide significantly impacts the end product. The strong seams created by these machines not only enhance the aesthetic appeal of the finished item but also improve its durability. This is crucial in industries where the longevity of products can dictate customer satisfaction and brand loyalty.

Technological Advancements

Recent advancements in technology have further enhanced the capabilities of heavy stitching machines. Features such as computerized sewing systems, automatic thread cutting, and programmable stitch patterns allow for greater precision and flexibility in production. These innovations enable manufacturers to meet the increasing demands of customization in textile production, catering to individual consumer preferences without sacrificing efficiency.

Conclusion

The heavy stitching machine stands as a testament to the progress made in textile manufacturing. Its ability to marry strength and precision has made it an indispensable tool in many industries. As technology continues to evolve, these machines will likely adapt, further enhancing their capabilities and reinforcing their role as a cornerstone in modern manufacturing practices. For manufacturers looking to stay competitive, investing in heavy stitching machines is not just an option but a necessity for success in today's market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025