Efficient Geotextile Stitching Machines for Enhanced Fabric Durability and Performance

The Importance of Geotextile Sewing Machines in Civil Engineering

In the realm of civil engineering and construction, the significance of geotextiles cannot be overstated. These synthetic fabrics, designed to enhance soil stability and drainage, play a crucial role in various applications, from road construction to slope stabilization and erosion control. To manufacture geotextiles effectively, specialized equipment, especially geotextile sewing machines, is essential.

Geotextile sewing machines are specifically designed to handle the unique properties of geotextile fabrics, which are often heavy, thick, and more durable than traditional textiles. These machines must be equipped with robust features to ensure they can effectively sew through multiple layers of fabric, as geotextiles are typically used in applications requiring durability and strength.

Key Features of Geotextile Sewing Machines

One of the primary features that differentiate geotextile sewing machines from standard sewing machinery is their needle and thread configuration. Geotextiles are usually made from polypropylene or polyester, materials that necessitate specialized thread types for optimal performance. Heavy-duty needles designed for penetrating thick fabrics ensure that the stitching is uniform and secure, preventing any potential tearing or failure during use.

Moreover, these machines often come with adjustable settings, enabling operators to modify stitch lengths and types depending on the requirements of the fabric and the specific application. Whether creating seams for geotextile bags used in erosion control or sewing together layers for stabilization mats, having the right stitch is crucial for success.

The Role of Automation

Modern geotextile sewing machines incorporate advanced technology to enhance productivity and precision. Automation features, such as programmable sewing patterns and computer-controlled settings, streamline the manufacturing process. This not only increases output but also ensures that each seam meets the exact specifications required for construction projects.

geotextile sewing machine

Quality control is another paramount aspect of using geotextile sewing machines. Many machines are equipped with sensors that detect variations in fabric tension, stitch accuracy, and overall material quality. By consistently monitoring these parameters, manufacturers can maintain high-quality standards, reducing the likelihood of defects and ensuring reliability in the final product.

Applications in Civil Engineering

The applications of stitched geotextiles are vast and varied within civil engineering. For instance, in road construction, geotextiles serve to reinforce soil and improve load distribution, thereby extending the lifespan of the roadways. The use of geotextiles helps in reducing the thickness of the subgrade, ultimately saving costs and resources.

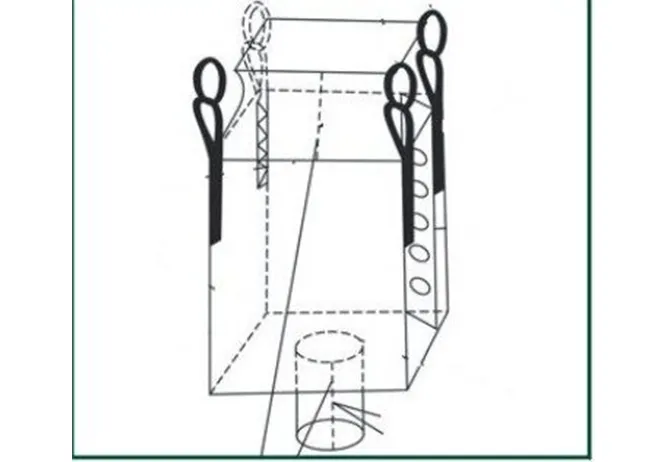

In erosion control, stitched geotextile bags filled with soil are employed to stabilize riverbanks and prevent soil erosion. These bags not only provide immediate protection but also encourage vegetation growth, further enhancing soil stability over time. The durability and strength of these bags rely heavily on the stitching quality achieved by reliable sewing machines.

Environmental Considerations

As the world continues to prioritize sustainability, the production of geotextiles and their applications in environmental preservation become increasingly relevant. Geotextiles can also be designed to degrade over time, supporting eco-friendly initiatives. The sewing machines used in manufacturing these materials must adapt to emerging technologies and sustainable fabric options, reflecting the industry's move toward greener practices.

Conclusion

Geotextile sewing machines play a pivotal role in the production of materials that are essential for modern engineering solutions. Their ability to create durable, high-quality seams not only enhances the effectiveness of geotextiles in various applications but also contributes to the safety and longevity of civil engineering projects. As construction demands evolve, the significance of these machines will only grow, ensuring that geotextiles remain a vital component in the pursuit of innovative and sustainable engineering practices. The marriage of technology and engineering in the context of geotextiles underscores the importance of investing in specialized equipment to meet the challenging demands of today’s construction industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025