Innovative Solutions for Compound Sewing Machines in Modern Textile Manufacturing

The Versatility of Compound Sewing Machines

In the world of textiles and garment production, efficiency and precision are paramount. Among the many tools available to tailors and manufacturers, the compound sewing machine stands out due to its unique design and functionality. This article delves into the significance of compound sewing machines, the mechanics behind their operation, and their impact on modern garment manufacturing.

Understanding Compound Sewing Machines

At its core, a compound sewing machine is a type of sewing machine that combines two different sewing processes into one streamlined operation. Generally, it features a walking foot mechanism, which allows the machine's upper layer of fabric to move in sync with the lower layer. This is particularly beneficial when working with multiple layers of fabric, varying textures, or materials that are difficult to handle.

The compound feed mechanism consists of a combination of differential feed, walking foot, and needle feed technology. This means that the machine excels at handling thick fabrics, such as leather, corduroy, and canvas, where standard sewing machines may falter due to slippage or uneven feeding. The ability of the compound machine to accommodate such materials has made it an essential tool in the production of bags, upholstery, and high-quality garments.

Mechanics Behind the Compound Feed

The compound feed system eliminates many common issues associated with fabric feeding during the sewing process. Conventional machines often rely on a single feed dog that engages with the fabric from underneath, which can lead to issues like puckering, warping, and uneven stitching. In contrast, the compound feed mechanism utilizes multiple points of contact that work in concert to walk the fabric through the machine.

The upper walking foot pulls the fabric along while the lower feed dog pushes it from beneath, ensuring that all layers of fabric move at the same rate. This synchronized motion significantly reduces the risks of fabric distortion and creates smoother seams. Additionally, the needle feed mechanism further assists in the accurate placement of the needle into the fabric, which is crucial for maintaining stitch quality on challenging materials.

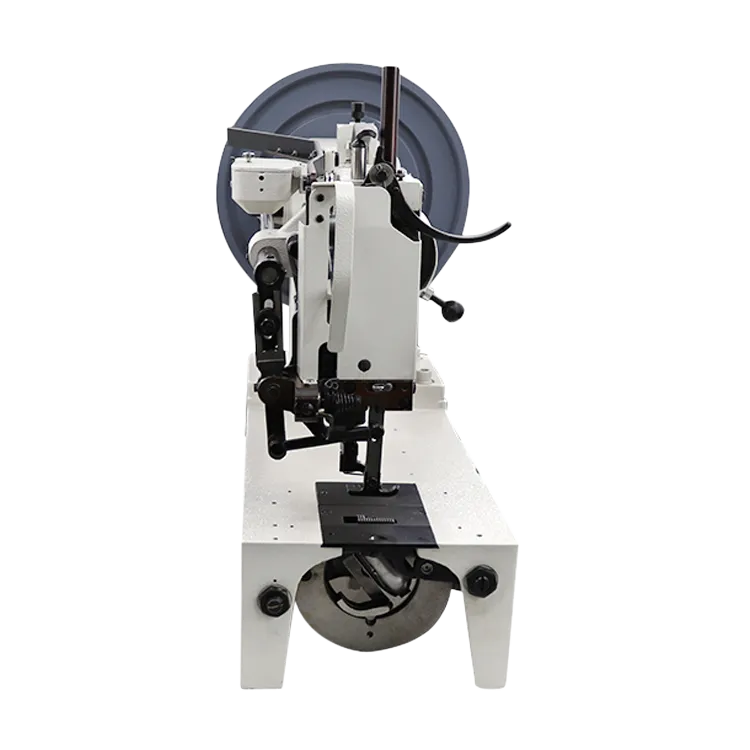

compound sewing machine

Applications in the Fashion and Textile Industry

The versatility of compound sewing machines has led to their widespread adoption in various sectors of the textile industry. Fashion designers and manufacturers utilize them for creating a wide array of products, from clothing to accessories. For example, in garment production, the compound machine can handle intricate tasks such as pleating, topstitching, and hemming with ease.

Moreover, the machine proves invaluable in the production of leather goods. The ability to sew through multiple layers of leather without compromising the integrity of the materials is essential in creating high-quality items such as handbags, belts, and footwear. Additionally, industries that work with heavy-duty fabrics—like outdoor gear companies—benefit immensely from the compound sewing machine's capacity to handle tough, resilient materials.

Conclusion The Future of Compound Sewing Machines

The evolution of compound sewing machines is ongoing, aided by advancements in technology. Today’s models come equipped with various features, such as electronic controls and programmable settings, which allow for greater flexibility and precision. This has opened new avenues for creative expression in garment design and production.

As sustainability becomes a more significant concern in the textile industry, the durability and efficiency of compound sewing machines will likely position them as a vital investment for manufacturers looking to improve production processes while minimizing waste. Their capacity to produce high-quality products efficiently will ensure that these machines remain relevant in the ever-changing landscape of fashion and textiles.

In conclusion, the compound sewing machine is an indispensable tool for anyone in the garment manufacturing business. Its unique feeding system not only enhances the quality of the finished product but also allows for greater creativity and innovation in design, making it a key player in the future of fashion production. As we continue to embrace technological advances, compound sewing machines will undoubtedly remain at the forefront, pushing the boundaries of what is possible in textile creation.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025