Efficient Production of Bulk Bags Using Advanced Bag Making Machinery

Understanding Bulk Bag Making Machines

In today’s fast-paced industrial landscape, the demand for efficient packaging solutions continues to grow. One of the most effective answers to this demand is the bulk bag making machine. These machines are specifically designed to produce large, durable bags that can efficiently store and transport various products, including powder, grain, chemicals, and construction materials.

What is a Bulk Bag?

Bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are large sacks typically made from woven polypropylene. They can carry a significant amount of weight, often up to 2,200 pounds (about 1,000 kg). Bulk bags are favored for their efficiency, cost-effectiveness, and ease of use in industrial settings. They are designed for stacking, making them ideal for shipping containers, warehouses, and other storage facilities.

The Role of Bulk Bag Making Machines

The bulk bag making machine plays a crucial role in the production process of these bags

. These machines can automate various stages of the manufacturing process, including weaving, cutting, sewing, filling, and squeezing the bags, leading to heightened efficiency and precision. The automation provided by these machines significantly reduces labor costs and production times, allowing manufacturers to meet high demand without compromising the quality of their products.Key Features of Bulk Bag Making Machines

1. Versatility Modern bulk bag making machines can produce a wide variety of bag sizes and configurations, accommodating different industry requirements. Adjustments can be made to cater to specific fabric types, bag dimensions, and special features such as spouts or discharge valves.

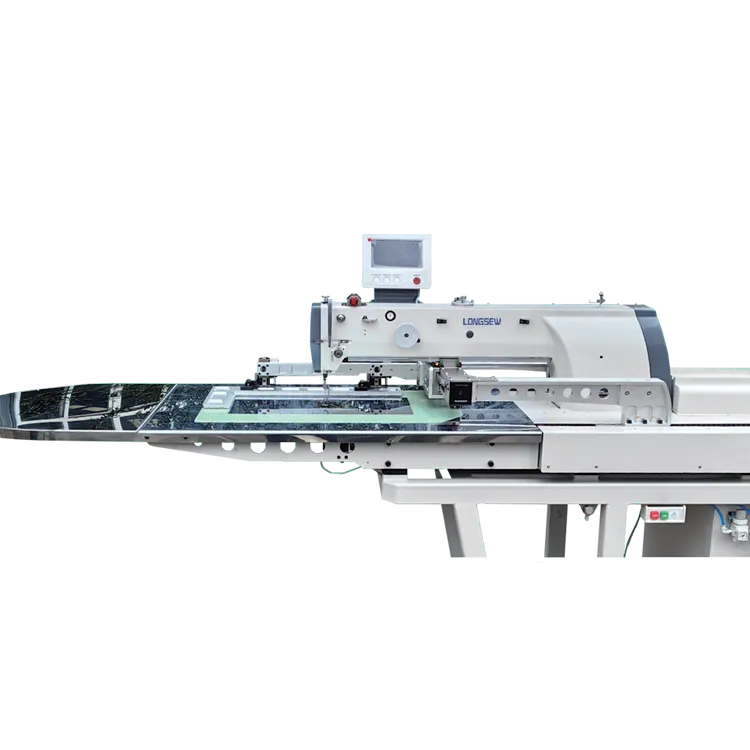

bulk bag making machine

2. Efficiency These machines are designed for high-speed operations, with some models capable of producing hundreds of bags per hour. This increased throughput allows companies to maximize their production capacity and minimize lead times.

3. Quality Control Many bulk bag making machines are equipped with advanced technology to ensure the highest quality standards. Automated systems can monitor the bag production process, checking for inconsistencies or defects in real-time.

4. Ease of Operation With user-friendly interfaces and automated controls, operators can easily manage the machine settings and monitor production processes, enhancing overall productivity and reducing the risk of errors.

Environmental Considerations

As environmental awareness increases, many manufacturers are looking for ways to reduce their ecological footprint. The bulk bag making industry is adapting by offering recyclable and biodegradable options for bags. Moreover, advancements in machine technology lead to reduced energy consumption during the production process.

Conclusion

The bulk bag making machine represents a significant advancement in industrial packaging. By enhancing production efficiency, maintaining high-quality standards, and accommodating the ever-changing needs of diverse industries, these machines play a vital role in the supply chain. As demand for bulk bags continues to rise, investing in a reliable bulk bag making machine can offer manufacturers a competitive edge in an increasingly crowded marketplace. With ongoing innovations, the future of bulk bag manufacturing looks promising, paving the way for more sustainable and efficient practices.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025