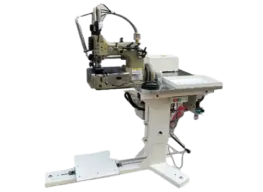

bag sewing machine

Exploring the World of Bag Sewing Machines

In recent years, the demand for bags in various forms has skyrocketed, leading to a burgeoning industry centered around the design and production of bags. From stylish handbags to durable backpacks, the versatility of bags makes them essential items for everyday life. However, behind every well-crafted bag is a powerful tool the bag sewing machine. This article delves into the significance of bag sewing machines, the technology behind them, and the future of bag manufacturing.

The Importance of Bag Sewing Machines

Bag sewing machines are specialized tools designed to stitch together various fabrics, materials, and components to create bags of all shapes and sizes. These machines play a crucial role in the manufacturing process, offering speed, efficiency, and precision that manual sewing simply cannot match. The ability to sew heavy materials like canvas, leather, and synthetic fabrics makes bag sewing machines indispensable for industrial production lines.

The importance of these machines extends beyond mere functionality. They allow for innovation in bag design, enabling manufacturers to experiment with various styles, sizes, and materials. As trends in fashion and utility evolve, bag sewing machines facilitate the rapid prototyping and production necessary to keep pace with consumer demand.

Types of Bag Sewing Machines

There are numerous types of bag sewing machines available on the market, each engineered for specific tasks and materials. Here are a few common types

1. Walking Foot Sewing Machines Ideal for sewing heavy materials, walking foot machines feature an additional feed mechanism that moves the top layer of fabric in unison with the bottom layer, preventing shifting. This is particularly useful when working with thick canvas or multiple layers of fabric.

2. Industrial Sewing Machines Designed for high-volume production, industrial sewing machines can handle large quantities of bags in a short time span. These machines often come equipped with specialized attachments and are built to withstand prolonged use.

3. Computerized Sewing Machines These machines offer advanced features such as programmable stitch patterns and automated thread tension control, making them perfect for intricate designs and customizable bags.

bag sewing machine

4. Post Bed Machines Designed for hard-to-reach areas, post bed machines are utilized in the production of bags with complex shapes or special features. The elevated sewing arm allows for more precise stitching in confined spaces.

5. Saddle Stitch Machines Commonly used in leather bag production, saddle stitch machines create strong and durable stitches that are both functional and aesthetically pleasing.

Technological Advancements

As technology continues to advance, bag sewing machines are becoming increasingly sophisticated. Modern machines often utilize computerized systems for increased accuracy and reduced errors. Features like automatic thread cutting, enhanced speed control, and built-in pattern libraries streamline the manufacturing process.

Additionally, innovations in materials have inspired the development of specialized sewing machines designed to handle new fabrics. For example, machines that can sew laminated or coated materials are in high demand as eco-friendly, water-resistant bags become more popular.

The Future of Bag Manufacturing

The future of bag manufacturing is bright, with countless opportunities for innovation and growth. As sustainability becomes a key focus in the fashion industry, there is a growing interest in biodegradable materials and ethical production practices. Bag sewing machines will play a critical role in this transition, helping manufacturers produce eco-friendly bags efficiently.

Furthermore, as e-commerce continues to rise, custom and personalized bags are in high demand. Bag sewing machines equipped with advanced features will enable manufacturers to cater to individual preferences and trends rapidly.

Conclusion

In conclusion, bag sewing machines are the backbone of the bag manufacturing industry, combining speed, precision, and innovative technology to meet growing consumer needs. As the market for bags continues to expand, these machines will evolve, helping manufacturers adapt to new materials and design trends while maintaining a focus on efficiency and sustainability. Whether you are a fashion designer, an entrepreneur, or simply a bag enthusiast, understanding the role and capabilities of bag sewing machines can provide invaluable insights into the world of bag production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025