Affordable Pricing Options for Automatic Industrial Sewing Machines

Understanding the Price of Automatic Industrial Sewing Machines

In the realm of modern manufacturing and textile production, automatic industrial sewing machines have become indispensable tools. Their efficiency, speed, and precision are revolutionizing the way garments and other fabric goods are created. However, one of the common queries from potential buyers and manufacturers alike is about the pricing of these sophisticated machines. Understanding the factors that influence the price of automatic industrial sewing machines is crucial for making informed purchasing decisions.

Types of Automatic Industrial Sewing Machines

Before diving into pricing, it's essential to understand that there are various types of automatic industrial sewing machines, each serving different purposes. Some of the most common types include

1. Flatbed Sewing Machines Suitable for a wide array of sewing tasks, they are versatile and commonly used in garment manufacturing. 2. Cylinder Bed Sewing Machines Ideal for sewing cylindrical items like sleeves and cuffs, these machines allow easy access to hard-to-reach areas. 3. Overlock Machines Used for finishing seams, they cut and stitch layers of fabric simultaneously, making them vital in preventing fraying. 4. Embroidery Machines These machines are tailored for adding intricate designs and are essential in the fashion and promotional products industries.

The type of machine influences its price, as specialized machines often come at a premium.

Key Factors Influencing Price

1. Functionality and Features The complexity of the machine affects its price significantly. Basic models may cost less, while high-end machines equipped with advanced features like automatic thread trimming, programmable sewing patterns, and touch-screen controls can be much pricier.

2. Brand Reputation Established brands with a history of reliability, service, and support often command higher prices. Investing in a well-known brand can sometimes save costs in the long run due to lower maintenance and better customer service.

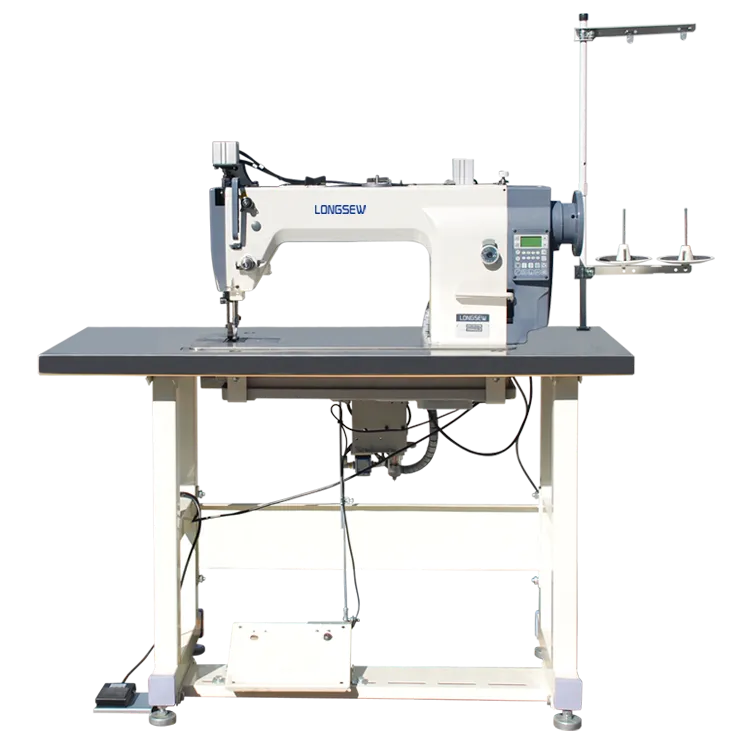

automatic industrial sewing machine price

3. Production Capacity The intended use of the machine, whether for small-scale operations or large production lines, impacts the price. Machines that can handle higher volumes tend to be more expensive due to their robust build and enhanced features.

4. Technology Integration Machinery that incorporates smart technology such as IoT (Internet of Things) capabilities, which enables remote monitoring and troubleshooting, will generally be priced higher. These features contribute to improved efficiency and reduced downtime.

5. Warranty and After-Sales Service Comprehensive warranties and reliable after-sales support add value to the purchase. Machines that come with longer warranties and better service options are likely to have a higher upfront cost but may offer greater peace of mind and reduced long-term expenses.

6. Supplier and Region Pricing can vary depending on the supplier and geographical region. Import duties, shipping costs, and local demand fluctuations can affect the final price tag. Buying from local distributors may help reduce shipping costs, but it might also limit choices compared to international suppliers.

Price Ranges

The price range for automatic industrial sewing machines can be quite broad. Entry-level machines suitable for small businesses or workshops may start at around $2,000 to $5,000. Mid-range machines, which offer a blend of features and performance, typically fall between $5,000 and $15,000. High-end models designed for large-scale manufacturing operations can exceed $20,000, reaching as high as $50,000 or more, especially if they are part of a complete production line setup.

Conclusion

Investing in an automatic industrial sewing machine is a significant decision for any manufacturing entity. While the price is a critical factor, it is essential to weigh it against the machine's functionality, brand reliability, and suitability for the intended production capacity. By understanding the elements that influence pricing, manufacturers can make sound choices that lead to enhanced productivity and ultimately, greater profitability. When considering such an investment, it is advisable to conduct thorough market research and evaluate different options to find the machine that best fits both budget and operational needs.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025