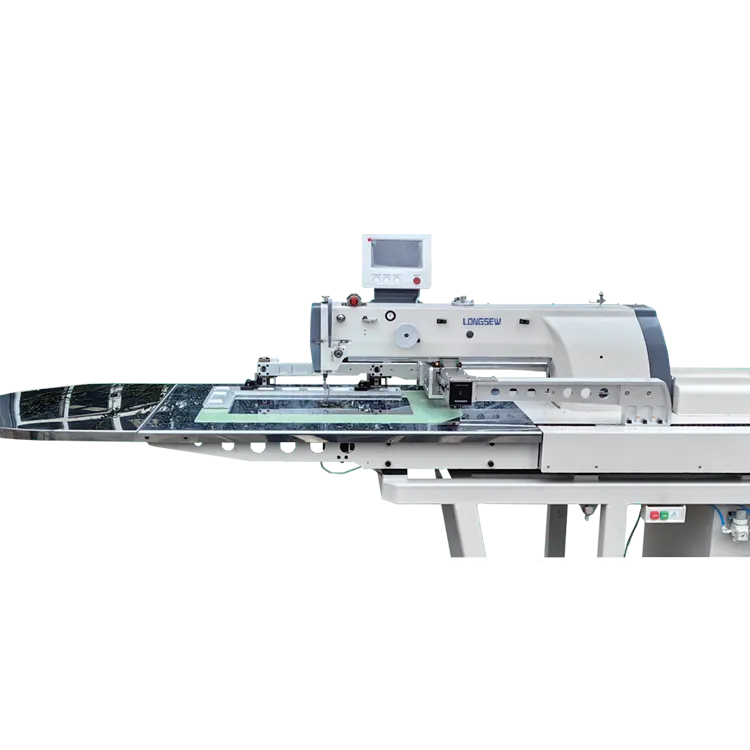

automatic sewing machine for factory

The Evolution of Automatic Sewing Machines for Factories

In the fast-paced world of textile manufacturing, the demand for efficiency and quality has led to significant advancements in technology. One of the most transformative innovations in this sector is the automatic sewing machine. These machines have revolutionized the production process in factories, enhancing both speed and precision while reducing human error.

Automatic sewing machines are designed to perform a variety of tasks that were once labor-intensive and time-consuming. Traditional sewing methods required skilled laborers to operate sewing machines manually, which often resulted in inconsistencies and slower production rates. With the introduction of automatic sewing machines, many tasks are now streamlined. These machines can be programmed to execute complex stitching patterns and handle various fabrics with ease.

One of the significant advantages of automatic sewing machines is their ability to increase productivity. Factories can now produce garments at a much faster rate, allowing them to meet high demand while minimizing production costs. For instance, in clothing factories, automatic sewing machines can work tirelessly, completing numerous garments in a fraction of the time it would take a human worker. This efficiency helps businesses respond quickly to market trends, reducing the time-to-market for new styles.

automatic sewing machine for factory

Moreover, automatic sewing machines contribute to enhanced quality control. With technology-driven precision, these machines can ensure that each stitch is consistent and meets the required specifications. This capability significantly reduces the risk of defects and improves overall product quality, which is critical for maintaining brand reputation in the competitive fashion industry.

The incorporation of automation in sewing also holds environmental benefits. As production becomes more efficient, factories can reduce waste by optimizing material usage. Many modern automatic sewing machines are built with sustainability in mind, utilizing less energy and minimizing the environmental footprint of manufacturing processes.

However, the rise of automatic sewing machines does pose challenges, particularly concerning employment. While these machines increase efficiency and productivity, they also reduce the need for manual labor in factories. This shift can lead to job displacement for many skilled workers. Therefore, it is essential for the industry to balance automation with the retraining of employees to take on new roles that involve managing and maintaining these advanced technologies.

In conclusion, automatic sewing machines are a testament to the significant technological advancements in the textile manufacturing sector. They not only enhance efficiency and quality but also present both challenges and opportunities for the workforce. As factories continue to embrace automation, the industry must find ways to integrate technology while empowering workers to thrive in this evolving landscape. The future of sewing is undoubtedly automated, and with it comes a new era of innovation in manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025