Innovative Sewing Machine Designed for Automation and Efficiency in Fashion Industry

The Emergence and Evolution of Automated Sewing Machines

In the vast landscape of textile production, automated sewing machines have emerged as game-changers, revolutionizing the industry and transforming the way garments are manufactured. These machines, equipped with advanced technology and precision engineering, have not only enhanced productivity but have also improved the quality and consistency of sewn products.

The Historical Context

The history of sewing machines dates back to the early 19th century with the development of the first sewing machine by Elias Howe in 1846. However, it was not until the introduction of automation that the sewing industry witnessed a significant transformation. The late 20th century brought forth the advent of computerized and automated sewing machines that have drastically changed standard operating procedures in factories. These machines marked a departure from the traditional manual sewing methods that dominated the industry for centuries.

Features of Automated Sewing Machines

Automated sewing machines are equipped with sophisticated features that enhance productivity and efficiency. They utilize computer technology to execute complex sewing patterns with remarkable precision. Some of the key features include

1. Computerized Controls Modern automated sewing machines come with digital interfaces that allow operators to program various sewing patterns. This capability minimizes human error and enhances the speed of production.

2. Multi-needle and Multi-thread Systems These machines can operate with multiple needles and threads simultaneously, allowing for intricate designs to be sewn in one go. This feature is especially valuable in the production of decorative garments and upholstery.

3. Automatic Thread Cutting Many industrial sewing machines now come with automatic thread cutting mechanisms. This feature eliminates the need for operators to manually cut threads, reducing production time and improving workflow.

4. Smart Sensors Advanced models include sensors that detect fabric thickness and adjust the tension and stitch length accordingly. This adaptability is essential for maintaining quality across various fabric types.

5. Integration with Other Technologies Many automated sewing machines are designed to integrate seamlessly with other technologies, such as laser cutters and embroidery machines, creating a fully automated production line.

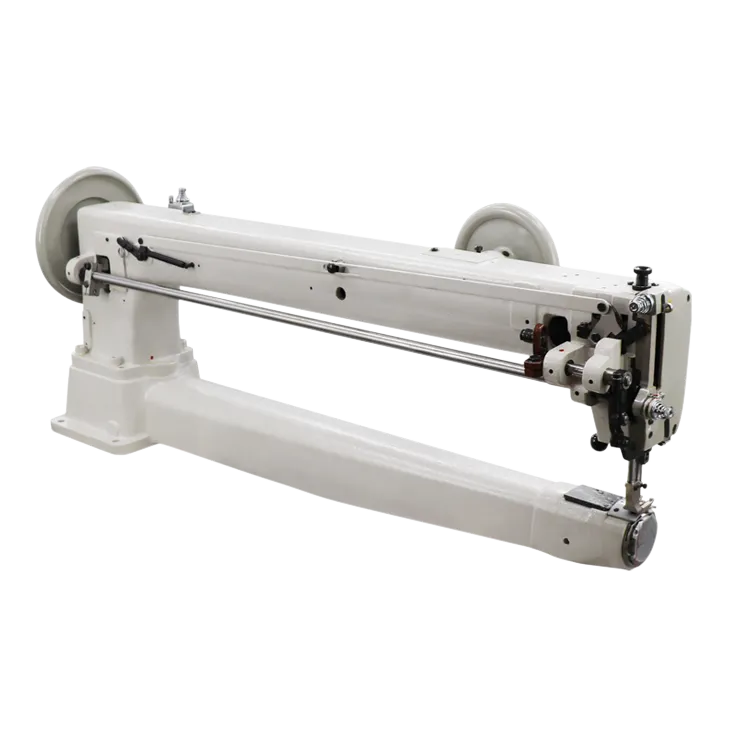

automated sewing machine

Impact on the Industry

The rise of automated sewing machines has had a profound impact on the garment manufacturing sector. The most significant benefits include

- Increased Production Speed Automated sewing machines can operate at speeds far surpassing that of manual sewing. This efficiency allows manufacturers to meet growing consumer demand rapidly.

- Consistent Quality Machines deliver uniform stitches and precise patterns, ensuring high quality and consistency across production batches. This reliability is crucial for brand reputation and customer satisfaction.

- Cost Reduction Although the initial investment in automated machines can be substantial, the reduction in labor costs and increased throughput lead to significant long-term savings. This financial efficiency enables manufacturers to compete more effectively in a global market.

- Skilled Workforce Reimagined While automation does reduce the number of manual labor positions, it also creates a demand for a new type of skilled workforce that can operate and maintain these sophisticated machines. Workers are now required to adapt to technology-enriched environments, ultimately fostering a culture of continuous learning.

Challenges and Future Prospects

Despite the advantages, the transition to automated sewing technologies is not without challenges. Initial costs can be a barrier for small businesses, and the integration process demands a shift in operational strategies. Furthermore, as automation continues to evolve, ethical concerns regarding job displacement arise.

Looking ahead, the future of automated sewing machines is promising. Innovations in artificial intelligence (AI) and machine learning are poised to further enhance the capabilities of these machines. For instance, AI could enable predictive maintenance, where machines proactively identify issues before they lead to downtime. Additionally, advances in robotics may allow for more intricate sewing tasks to be performed autonomously.

Conclusion

Automated sewing machines have undoubtedly transformed the textile industry, ushering in an era of unprecedented efficiency and creativity. As technology continues to advance, the future of garment manufacturing will likely hinge on striking a balance between automation and the human touch—ensuring quality, innovation, and sustainability in a constantly evolving market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025