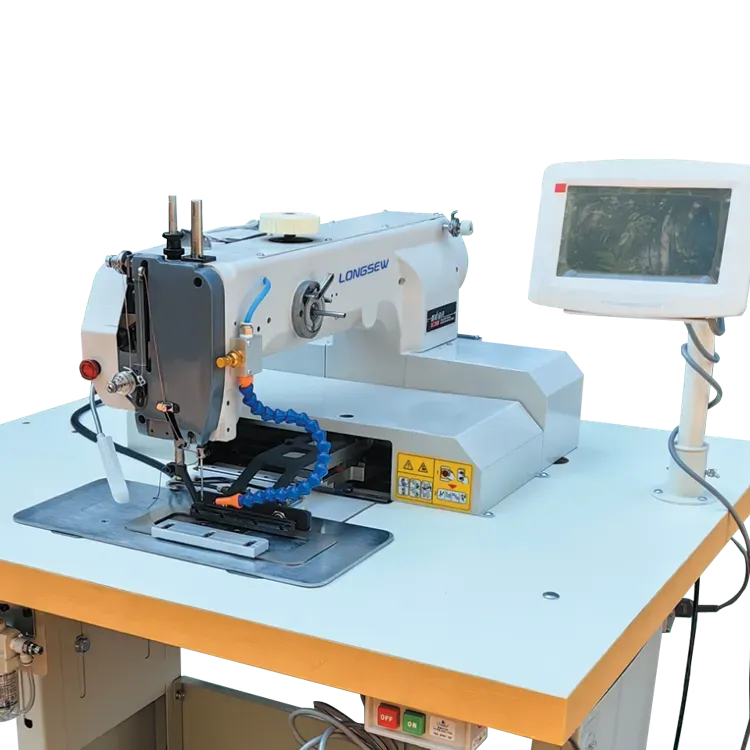

rigging sewing machine

The Evolution and Importance of Rigging in Sewing Machines

In the world of textile manufacturing, the interplay between design and functionality is paramount. One of the most critical components of this relationship lies in the rigging of sewing machines. Rigging in this context refers to the configuration and adjustment of a sewing machine’s components to ensure optimal performance, allowing it to meet the intricate demands of fabric manipulation and seam construction.

Understanding Rigging in Sewing Machines

Rigging a sewing machine involves aligning various parts to enhance its capability. This includes adjusting the tension of threads, the height of the presser foot, and the needle’s position. Each of these adjustments plays a significant role in determining the machine's overall efficiency and the quality of the stitches produced. When rigged properly, a sewing machine can sew through different types of fabrics, from delicate silks to sturdy denims, without causing snags or uneven stitches.

The art of rigging is often overlooked by novice sewers. However, for professionals in the textile industry, understanding and mastering the rigging of sewing machines is indispensable. A well-rigged machine can drastically improve the speed and precision of the sewing process, leading to better productivity and fewer wasted materials.

The Components of Rigging

1. Thread Tension Maintaining the correct thread tension is crucial. Too tight a tension can cause threads to break, while too loose a tension can result in loose, uneven stitches. Proper rigging means setting the tension settings according to the type of thread and fabric being used.

2. Needle Position The position of the needle can also affect stitch quality. A needle that is not correctly aligned can lead to skipped stitches or unsightly seams. Rigging involves ensuring that the needle is securely fastened and correctly aligned horizontally and vertically relative to the feed dogs.

rigging sewing machine

3. Presser Foot Height The presser foot’s job is to hold the fabric in place while the needle sews. Depending on the thickness of the fabric, the presser foot may need adjusting. A well-rigged presser foot will exert the right amount of pressure, ensuring smooth feeding of the fabric without damaging it.

4. Feed Dogs These are the components that move the fabric through the machine. Proper rigging involves adjusting the feed dogs to match the fabric weight and type. They must be set to rise above the plate sufficiently to grip the fabric but not so high that they interfere with the sewing process.

Benefits of Effective Rigging

Investing time in rigging a sewing machine offers numerous benefits. Firstly, it enhances the quality of the finished product. A machine that is properly rigged will create even, sturdy seams that can withstand use over time. This is particularly important in the fashion industry, where the visual and structural integrity of clothing items is crucial.

Secondly, effective rigging can lead to increased efficiency. Misalignment and improper tension setups can cause delays and repeated adjustments, which can slow down production. By ensuring that all components are rigged correctly from the outset, sewers can maximize their productivity and reduce the chances of encountering issues mid-project.

Lastly, learning the rigging process instills a sense of confidence in a sewer’s skills. Understanding how to adjust a sewing machine empowers sewers to tackle a broader range of projects and fabrics, enhancing creativity and innovation.

Conclusion

In summary, the rigging of sewing machines is an essential skill that significantly impacts the quality and efficiency of sewing tasks. Through an understanding of the components involved and their proper adjustments, both novice and experienced sewers can master the art of rigging, ensuring their machines operate at peak performance. As the textile industry continues to evolve, so does the importance of technology and skill in producing high-quality fabric goods. Investing time in mastering these rigging techniques is not only beneficial for individual projects but also for the collective advancement of sewing practices in the industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025