PP Bag Stitching Machine for Efficient Packaging Solutions and Production Optimization

The Evolution and Importance of PP Bag Stitching Machines

In the realm of manufacturing and packaging, efficiency and precision are key drivers of success. One critical component of the packaging industry is the PP (polypropylene) bag stitching machine. These machines have revolutionized the way businesses package and secure their products, ensuring durability and reliability in one of the most ubiquitous forms of packaging.

Understanding PP Bags

Polypropylene bags are widely used in various sectors, including agriculture, construction, and food processing. Their lightweight yet sturdy nature makes them an ideal choice for transporting and storing goods. These bags are resistant to moisture, chemicals, and UV light, which enhances their longevity, making them a preferred choice for both manufacturers and consumers.

Given the exponential growth in the production and demand for PP bags, the technology associated with stitching and sealing these bags has also advanced significantly. A PP bag stitching machine is specifically designed to automate the process of sealing the open ends of these bags, ensuring they remain intact during transport and storage.

The Functionality of PP Bag Stitching Machines

Modern PP bag stitching machines are equipped with state-of-the-art features that streamline operations. They can be operated manually or automatically, depending on the production scale and requirements of the business. The basic function of these machines is to stitch or seal the open ends of polypropylene bags securely.

The stitching machines come with various technologies, such as

1. Sewing Mechanism Most machines use specialized needles and threads designed to penetrate tough polypropylene material without compromising quality. This work allows for strong seams that can withstand significant weight and stress.

2. Speed and Efficiency Advanced stitching machines can achieve high-speed operations, significantly increasing production output. Some models can stitch up to 1,200 bags per hour, which is essential for meeting high-demand scenarios in fast-paced industries.

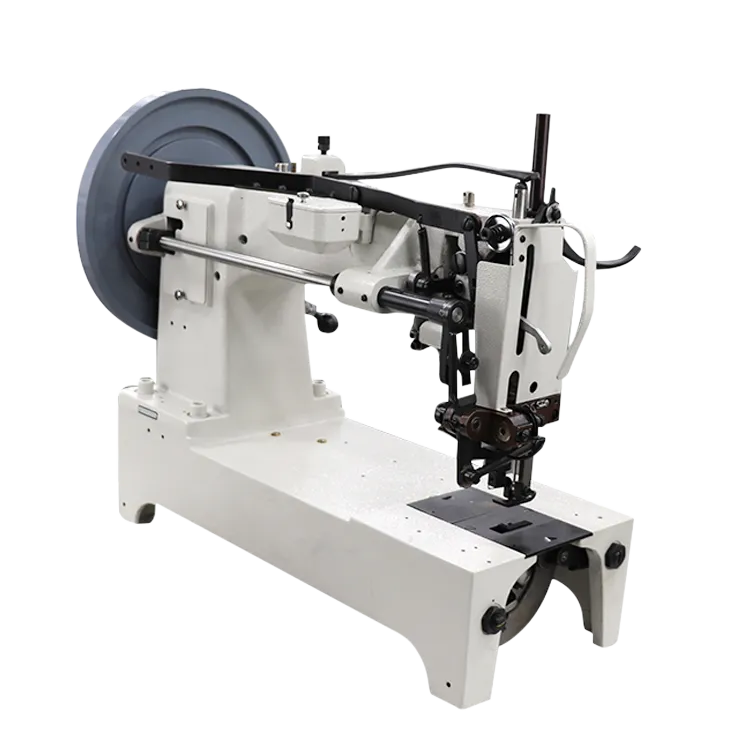

pp bag stitching machine

4. Integration with Other Systems Modern PP bag stitching machines can be integrated with filling and sealing lines, allowing for a seamless packaging process. This integration enhances the overall efficiency of operations, reducing labor costs and the risk of errors.

The Benefits of Using PP Bag Stitching Machines

Investing in PP bag stitching technology offers numerous advantages. Firstly, it improves productivity significantly. With automated stitching processes, businesses can produce large volumes of bags in a fraction of the time it would take manually.

Secondly, these machines ensure a consistent level of quality. Automated stitching minimizes human error, leading to uniformly sealed bags that enhance product safety during transport. Consumers can have confidence in the integrity of the packaging, which directly affects brand reputation.

Additionally, the durability of stitched PP bags contributes to sustainability. Businesses can reduce waste by minimizing the number of damaged packages that result from poor sealing. The long-lasting nature of polypropylene also means that these bags can be reused or recycled, aligning with modern sustainability practices.

Challenges and Considerations

Despite the myriad benefits, manufacturers must consider several factors before investing in a PP bag stitching machine. The initial costs can be substantial, particularly for high-speed, advanced models. It's crucial for businesses to analyze their production needs and pick a machine that offers the best return on investment.

Moreover, maintenance is key to the longevity of these machines. Regular upkeep and servicing are essential to prevent breakdowns that can lead to costly downtime. Training staff on proper operation and maintenance is equally important to maximize efficiency.

Conclusion

As the packaging industry continues to evolve, the importance of reliable and efficient PP bag stitching machines cannot be overstated. They play an instrumental role in ensuring that products are securely packaged and ready for delivery to consumers around the globe. With advancements in technology and a growing focus on sustainability, these machines represent a vital investment for any business looking to enhance their packaging operations and ensure the integrity of their products. In this fast-paced world of production, the PP bag stitching machine stands out as a beacon of efficiency and reliability, paving the way for future innovations in the packaging sector.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025