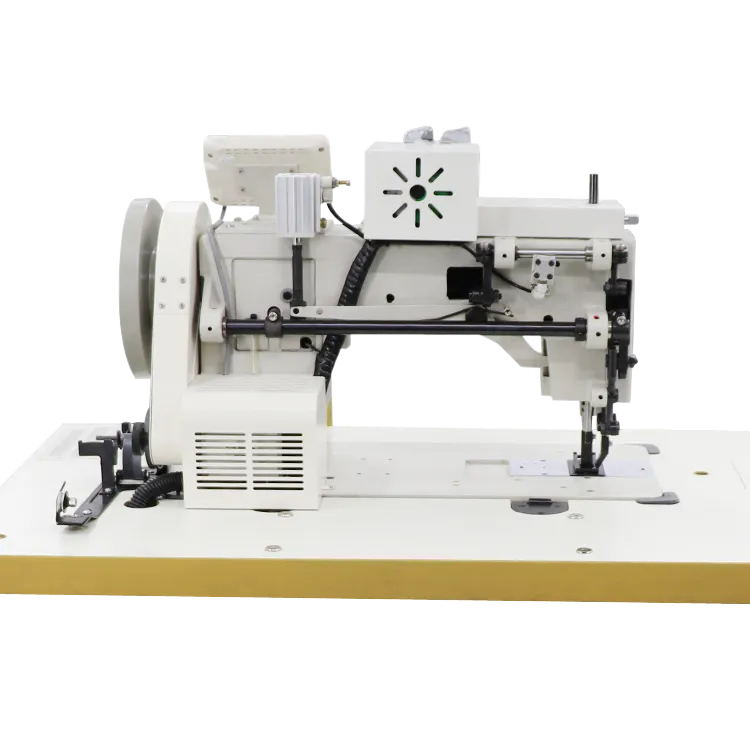

pp bag hand stitching machine

The Versatility and Importance of PP Bag Hand Stitching Machines

In the realm of manufacturing and packaging, polypropylene (PP) bags have emerged as a popular choice due to their durability, lightweight nature, and versatility. From agricultural products to industrial applications, these bags serve a plethora of functions. However, the production and quality of PP bags depend not just on the materials used, but also significantly on the machinery involved in their manufacturing. One such critical piece of equipment is the PP bag hand stitching machine, which plays an essential role in ensuring that these bags are securely sealed and durable for various uses.

Understanding PP Bags

Polypropylene bags are made from a thermoplastic polymer, known for its resistance to wear and tear, moisture, and chemicals. These bags are used for carrying a wide range of items including grains, fertilizers, building materials, and even retail products. The advantages of PP bags over traditional paper or plastic bags include their reusability, reduced environmental impact when properly recycled, and their ability to be produced at a lower cost. Thus, the demand for PP bags continues to rise in various sectors.

The Role of Hand Stitching Machines

In the process of manufacturing PP bags, it is crucial to ensure that they are not only made from high-quality materials but also sealed properly to prevent any spillage or damage to the contents. This is where PP bag hand stitching machines come into play. These machines allow for the manual stitching of the bags, ensuring that each bag is securely closed and capable of holding its intended load reliably.

Hand stitching machines are particularly valuable in small to medium-sized production settings where automation may not be feasible. With the ability to adjust stitching techniques manually, operators can produce customized bag sizes and stitch patterns according to specific requirements. This flexibility enables manufacturers to meet the diverse needs of their clients without the constraints of rigid automated machinery.

Advantages of Using Hand Stitching Machines for PP Bags

pp bag hand stitching machine

1. Cost-Effectiveness For smaller operations, hand stitching machines provide a cost-effective solution for sealing PP bags without the significant investment required for fully automated machines. These machines are typically less expensive to purchase and maintain.

2. Customizability Hand stitching allows manufacturers to easily switch between different bag sizes and stitching styles. This adaptability is excellent for businesses that require variety or operate in niche markets where specific bag designs may be needed.

3. Quality Control Manual operation of stitching machines enables greater attention to detail. Operators can inspect each bag during the stitching process, ensuring that there are no defects that could compromise the integrity of the bag.

4. Portability Hand stitching machines are often lightweight and portable, making them useful for operations that may need to stitch bags in different locations or require the ability to move the machines between workstations.

5. Workforce Training While more traditional, hand stitching does not require the same level of technical skill as programming automated machines. This means that training workers to use hand stitching machines can be quicker and less complex, allowing businesses to onboard new employees more efficiently.

Conclusion

In conclusion, PP bag hand stitching machines hold a significant place in the production of polypropylene bags. They provide a perfect balance of quality, flexibility, and cost-effectiveness, making them an essential tool for many manufacturers. As the demand for PP bags continues to grow, understanding the importance of hand stitching techniques and the machinery involved can greatly enhance operational efficiency and product reliability. Manufacturers looking to stay competitive in the market should consider integrating hand stitching machines into their production processes to ensure quality and adaptability in their bag offerings. With their wide range of applications and benefits, PP bags produced with the help of these machines will remain a staple in various industries for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025