Marine Upholstery Sewing Machine - Durable and Efficient Solutions for Marine Fabrication

Marine Upholstery Sewing Machines An Essential Tool for Nautical Crafts

When it comes to marine upholstery, the importance of a reliable sewing machine cannot be overstated. Boats and yachts often require high-quality upholstery to withstand harsh maritime conditions. This is where marine upholstery sewing machines come into play. These specialized machines are designed to tackle the unique challenges presented by sewing marine fabrics, ensuring durability, water resistance, and an aesthetically pleasing finish.

What Sets Marine Upholstery Sewing Machines Apart?

Marine upholstery fabrics are typically heavier and thicker than standard upholstery materials. They must resist water, UV rays, and the wear and tear from saltwater exposure. Consequently, not all sewing machines can handle these types of materials effectively. Marine upholstery sewing machines are built with robust motors and components that can sew through multiple layers of heavy fabric, often equipped with features that cater specifically to nautical applications.

One of the critical features of a good marine upholstery sewing machine is its ability to use heavy-duty threads. These threads are usually made from polyester or nylon, providing extra strength and resistance to fraying. Many marine sewing machines also utilize walking feet or dual feed mechanisms, which help to evenly feed thick materials through the machine without puckering or shifting. This is particularly important when working on large upholstery projects like boat cushions, biminis, or covers.

The Right Machine for the Job

When choosing a marine upholstery sewing machine, several factors should be considered. First and foremost is the type of projects you plan to undertake. For occasional home or DIY projects, a mid-range machine may suffice. However, for commercial applications or frequent, heavy usage, investing in a high-quality industrial machine may be necessary to handle the rigorous demands of marine upholstery work.

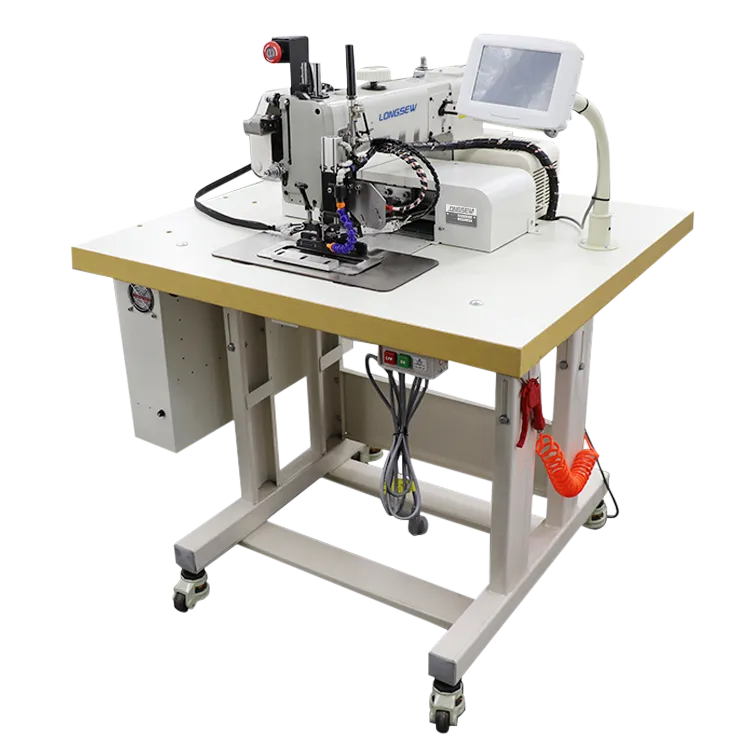

marine upholstery sewing machine

Another important consideration is the machine's needle and presser foot compatibility. Marine upholstery requires specialized needles, often significantly thicker and designed for heavier fabrics. The presser foot should also be able to accommodate thick layers, which is crucial for maintaining consistent tension and stitch quality throughout the sewing process.

Tips for Successful Marine Upholstery Projects

To ensure successful marine upholstery projects, proper preparation and technique are essential. Begin by prewashing your fabric to remove any chemicals or finishes that could affect adhesive or stitching. Always use high-quality marine-grade materials that are specifically designed for outdoor use, as they offer the best protection against mold, fading, and tearing.

When setting up your machine, it's critical to use the appropriate needle size and thread type for your project. Take the time to test your machine's tension settings with scrap fabric before starting your project. This will help you achieve the perfect stitch and avoid frustrating adjustments later on.

Conclusion

In summary, a marine upholstery sewing machine is an invaluable asset for anyone involved in nautical design or boat maintenance. With the right tools and techniques, you can elevate your marine projects, ensuring they are not only functional but also visually appealing. Whether you're creating custom boat covers, cushions, or other upholstery, investing in a quality sewing machine will undoubtedly enhance your craftsmanship and the longevity of your work on the water.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025