Sewing Machines for Leather Gloves Essential Tools for Quality Craftsmanship

The Intricacies of Leather Glove Sewing Machines

In the world of apparel manufacturing, the crafting of leather gloves is an art form that combines tradition with precision engineering. At the heart of this craft lies the leather glove sewing machine, a specialized tool designed to create durable, aesthetically pleasing gloves tailored to various needs. This article explores the technology behind leather glove sewing machines, their importance in production, and the nuances of sewing leather.

The Importance of Leather Gloves

Leather gloves are not just a fashion accessory; they serve numerous practical purposes. From providing warmth in winter to offering protection in various industrial settings, the demand for high-quality leather gloves remains strong. The craftsmanship involved in creating these gloves directly affects their quality, comfort, and durability. Thus, efficient and effective sewing machines are critical in meeting market expectations.

Types of Leather Glove Sewing Machines

Leather glove sewing machines come in various forms, each suited for specific tasks within the glove-making process. The most common types include

1. Flat Bed Sewing Machines Ideal for straight seams and simple designs, these machines allow for easy handling of flat pieces of leather.

2. Cylinder Bed Sewing Machines These are designed with a cylindrical arm, making them perfect for sewing gloves as they facilitate the movement of the glove around the machine’s arm, ensuring a smooth stitching process.

3. Post Bed Sewing Machines Similar to cylinder bed machines, post bed machines allow for more intricate designs and details. They are particularly useful when working on gloves with complex seams or decorative elements.

4. Overlock Machines Often used in finishing edges, overlock machines create a professional look while preventing fraying. While not exclusive to glove manufacturing, they play a crucial role in the overall production process.

Features of Leather Glove Sewing Machines

Modern leather glove sewing machines are equipped with a variety of features that enhance their functionality

- Multiple Needle Options Different stitches require different needles. Machines can be fitted with various needle types to accommodate standard or specialized stitching.

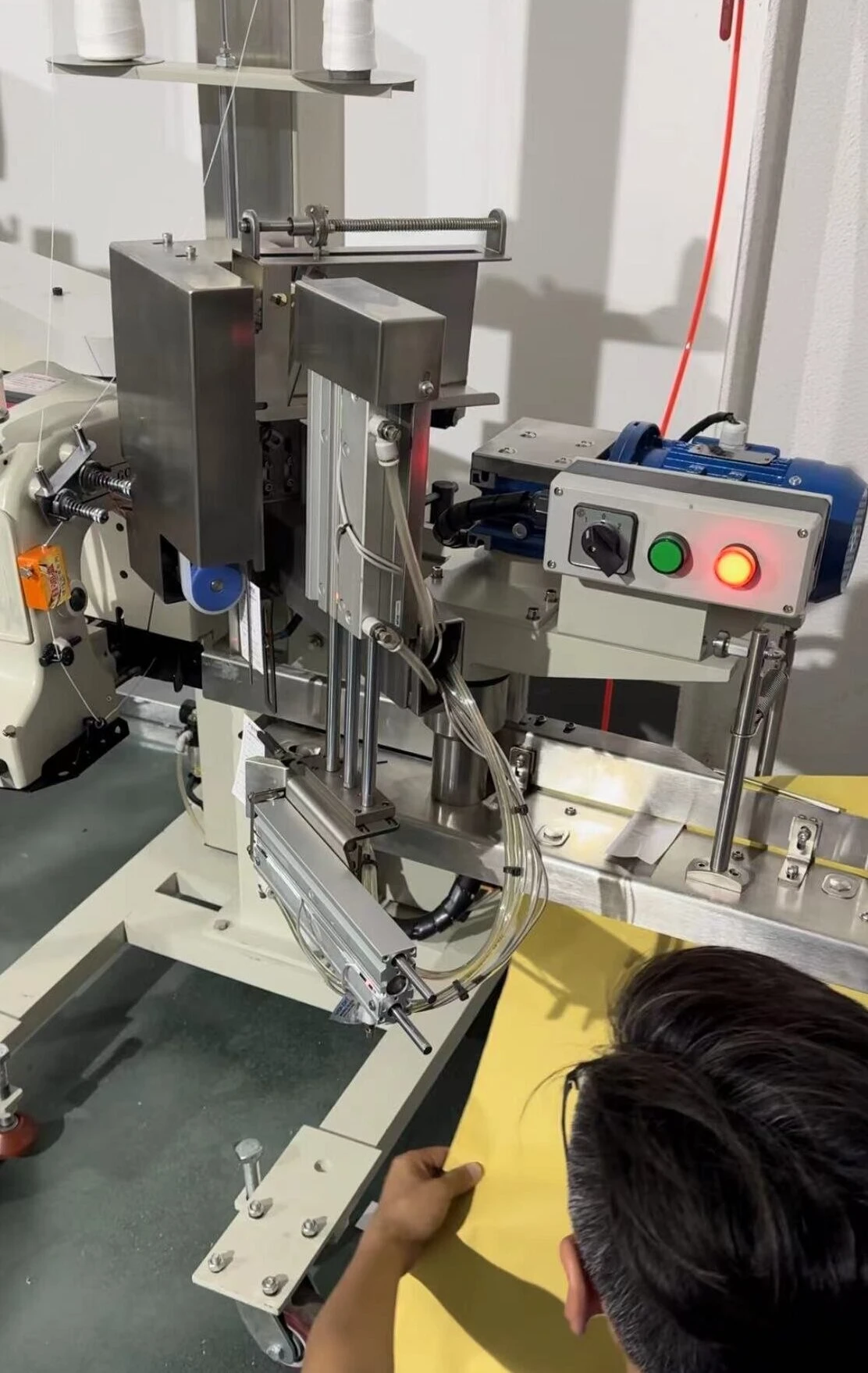

leather glove sewing machine

- Adjustable Stitch Length Manufacturers can adjust the stitch length according to the thickness of the leather and the intended design. Precision in stitch length is imperative for both aesthetics and comfort.

- Automatic Thread Tension Control This feature allows for consistent stitching quality, especially important when sewing thicker leather.

- Walking Foot Mechanism This mechanism ensures that the leather moves smoothly under the presser foot, preventing slippage and ensuring even feeding.

The Challenges of Sewing Leather

Sewing leather presents unique challenges compared to other fabrics. Leather is thick, typically heavier, and less forgiving than textiles, making it essential for sewing machines to offer high power and stability. Additionally, different types of leather require specific handling and stitching techniques, as they can stretch or warp during sewing. A good leather glove sewing machine must be capable of handling these variations without compromising the integrity of the gloves.

Techniques for Working with Leather

To maximize the performance of leather sewing machines, certain techniques should be employed

- Use of Specialty Threads For leather gloves, polyester or nylon threads are recommended for their strength.

- Proper Knife and Blade Maintenance Keeping blades sharp ensures clean cuts, which are crucial for high-quality seams.

- Prepping Leather Properly conditioning leather before sewing can enhance its pliability and reduce the risk of damage during the stitching process.

Conclusion

The leather glove sewing machine is an essential component in the art of glove making. With advancements in technology and an array of features, these machines enable manufacturers to produce gloves that are both functional and stylish. As the demand for leather gloves continues to rise, understanding the intricacies of sewing machines and the challenges of working with leather becomes increasingly important. By combining skill with the right tools, manufacturers can uphold the tradition of leather craftsmanship while meeting contemporary needs. Whether for fashion or utility, leather gloves remain a staple product, underscoring the significance of efficient production techniques in their creation.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025