leather machinery

The Evolution and Significance of Leather Machinery

Leather has been an essential material for various applications, including fashion, automotive, and upholstery, for centuries. The process of transforming raw animal hides into finished leather involves several intricate steps, each facilitated by specialized machinery. Understanding leather machinery is crucial for anyone involved in the tanning and leather production industry.

The history of leather machinery can be traced back to the early days when artisans relied solely on manual tools. As demand for leather products grew, so did the need for more efficient production methods. The Industrial Revolution marked a turning point, introducing steam-powered machines that revolutionized the tanning process, increasing both speed and efficiency.

Modern leather machinery encompasses a wide range of equipment designed to address the various stages of leather processing. One of the primary machines used is the fleshing machine, which removes excess flesh and fat from hides, ensuring a clean starting material for tanning. Following this, the tanning process employs machines such as the drum tanning machine, where hides are immersed in a tanning solution to preserve them and prevent decay. This step is vital as it determines the quality and characteristics of the final leather product.

Another key piece of machinery is the splitting machine, which divides hides into layers, enabling manufacturers to produce leather of varying thicknesses and textures. This flexibility allows for greater innovation in design and application. Additionally, finishing machines play a crucial role in enhancing the appearance and durability of leather. Processes like surface coating and polishing are essential to achieve the desired look and feel, making the leather more appealing to consumers.

leather machinery

The significance of leather machinery extends beyond mere production efficiency. It also plays a vital role in quality control. Advanced machinery features precise controls and automation, allowing for consistent results and reducing waste. This is particularly important in an industry increasingly pressured to adopt sustainable practices, as efficient machinery can help minimize resource consumption and environmental impact.

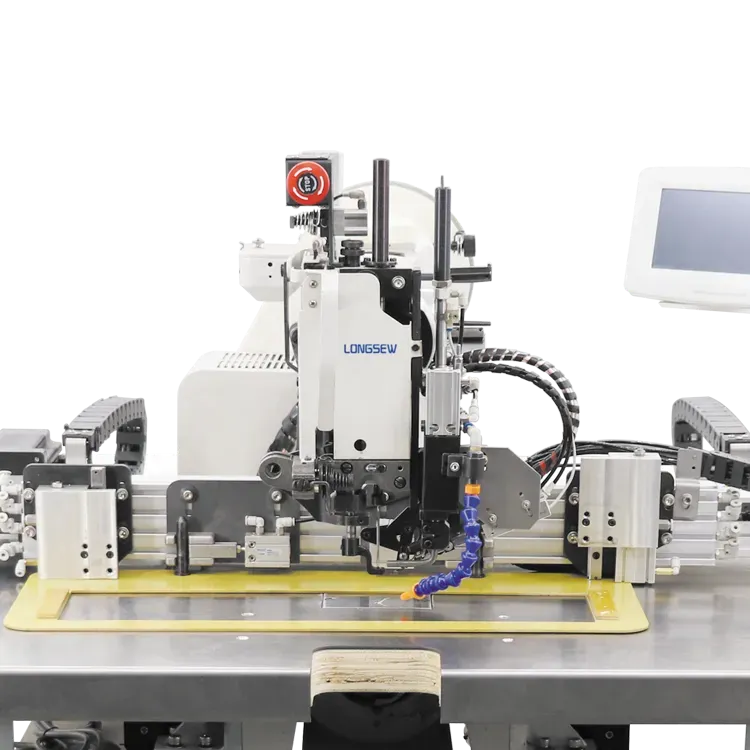

Moreover, with the advent of technology, modern leather machinery now often incorporates digital solutions for greater precision and customization. For instance, computer-controlled cutting machines enable complex designs to be replicated accurately, catering to a customer's specific needs. This technological advancement enables producers to respond quickly to changing market trends, further driving innovation.

The global leather industry is continuously evolving, with machinery becoming more sophisticated and integrated. Manufacturers are focusing on developing eco-friendly processes, utilizing machinery that reduces water usage and improves energy efficiency. This shift not only addresses consumer demand for sustainable products but also aligns with global regulatory standards on environmental impact.

In conclusion, leather machinery plays an indispensable role in the leather production process, enhancing efficiency, quality, and sustainability. As technology continues to advance, the potential for innovation within this sector remains vast, ensuring that leather will continue to be a favored material for generations to come. Understanding this machinery is vital for stakeholders who wish to thrive in a competitive and ever-evolving industry landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025