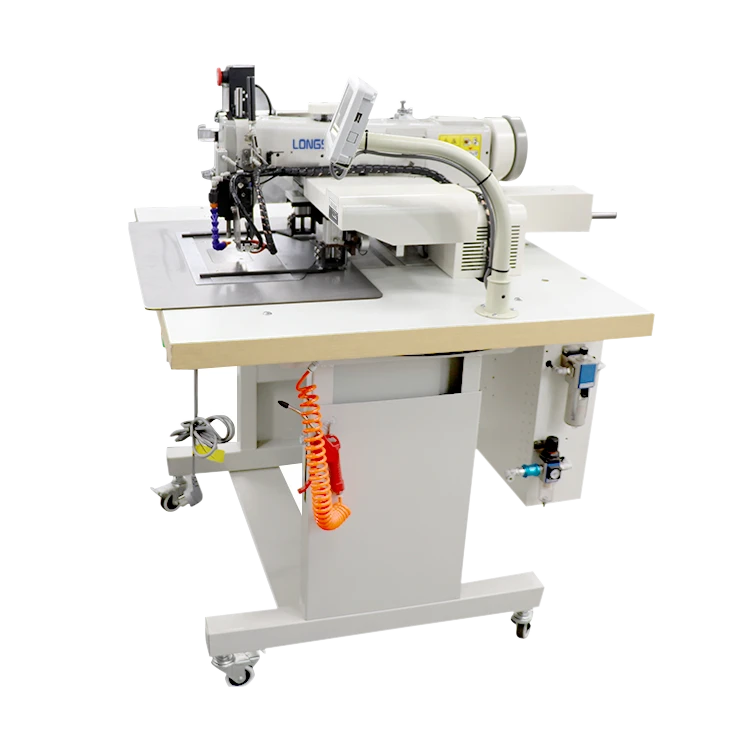

leather bag making machine

The Art of Leather Bag Making Machines

In the ever-evolving world of fashion and accessories, leather bags have always held a place of prominence. The timeless appeal of leather, combined with the craftsmanship behind making leather bags, makes them a must-have item for consumers worldwide. With advancements in technology, the process of creating leather bags has been transformed significantly by the introduction of leather bag making machines.

Leather bag making machines represent a blend of art and technology, enabling artisans and factories to produce high-quality leather goods efficiently. These machines cater to various stages of the bag-making process, including cutting, stitching, and finishing. One of the primary benefits of these machines is their efficiency. They can handle leather and other materials much faster than manual processes, allowing manufacturers to meet high demands without compromising quality.

For instance, cutting machines utilize precision technology to ensure that patterns are accurately cut from leather, sometimes with the use of lasers for intricate designs. This eliminates human error and optimizes the use of materials, reducing waste. The precision cuts ensure that each piece fits perfectly, which is essential for the structural integrity and aesthetic appeal of the final product.

Stitching is another critical stage in the production of leather bags. Automated stitching machines have revolutionized this part of the process. They produce consistent, strong stitches that enhance the durability of bags. These machines ensure that even the most complex designs can be reproduced with ease, maintaining uniformity across batches. This consistency is crucial for brands looking to establish a reputation for quality and reliability in the competitive fashion market.

leather bag making machine

Moreover, leather bag making machines often incorporate advanced technology such as computer numerical control (CNC) systems. These systems allow for intricate designs and customizations that were once labor-intensive and time-consuming. With the ability to program specific designs, manufacturers can reduce the lead time for new collections and adapt quickly to changing market trends.

Another significant advantage of using leather bag making machines is the potential for cost savings. While the initial investment in machinery may be considerable, the long-term savings through increased production efficiency, reduced labor costs, and minimized material waste often outweigh these costs. This efficiency not only benefits large-scale manufacturers but also empowers small businesses and independent artisans to produce high-quality products while keeping prices competitive.

Despite the efficiency that machines bring to the leather bag making process, the role of skilled artisans remains indispensable. The human touch is irreplaceable when it comes to design innovation, quality control, and the fine details that elevate a leather bag from good to exceptional.

In conclusion, leather bag making machines bridge the gap between tradition and technology. They have transformed the production process, enabling mass production of high-quality leather goods while preserving the artisanal essence that leather is known for. As the fashion industry continues to innovate, these machines will play a pivotal role in shaping the future of leather accessories, allowing creators to focus on design while enhancing efficiency and quality in production. Whether for small workshops or large factories, the impact of leather bag making machines is undeniable, paving the way for a new era in leather craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025