High-Performance Lock Stitch Machine for Jumbo Bag Production Efficiency

The Jumbo Bag Lock Stitch Machine Revolutionizing Industrial Packaging

In the fast-paced world of industrial packaging, efficiency and precision are paramount. One of the key innovations that have emerged to meet these needs is the jumbo bag lock stitch machine. This advanced piece of equipment offers a host of advantages for industries involved in the packaging of bulk materials, such as agriculture, chemicals, and construction.

Understanding Jumbo Bags

Before diving into the specifics of the lock stitch machine, it’s essential to understand what jumbo bags are. Also known as FIBCs (flexible intermediate bulk containers), jumbo bags are large bags made from woven polypropylene that are designed to hold and transport bulk materials. Their ability to carry substantial weights—often up to 2000 kg—makes them a popular choice across various sectors. However, the integrity of these bags is crucial, as a failure during transport can lead to significant financial losses and safety hazards.

The Importance of Lock Stitch Technology

The lock stitch technology is a fundamental feature of the jumbo bag lock stitch machine. This type of stitch is created by interlocking two threads—one from the needle and the other from the bobbin—creating a strong, durable seam. This robust stitching method is particularly suited to the demands of jumbo bags, as it provides increased tensile strength and resistance against fraying.

In addition, the lock stitch is less likely to unravel compared to other stitching methods, ensuring that the contents remain securely packaged throughout transit and storage. For industries that require the transportation of heavy or granular materials, the integrity of the packaging is non-negotiable.

Enhanced Operational Efficiency

One of the standout features of the jumbo bag lock stitch machine is its operational efficiency. These machines are designed to handle high-volume production without sacrificing quality. Many models are equipped with automated feeding systems, which streamline the stitching process and reduce the need for manual labor. This not only speeds up production but also minimizes the risk of human error, leading to consistent, high-quality results.

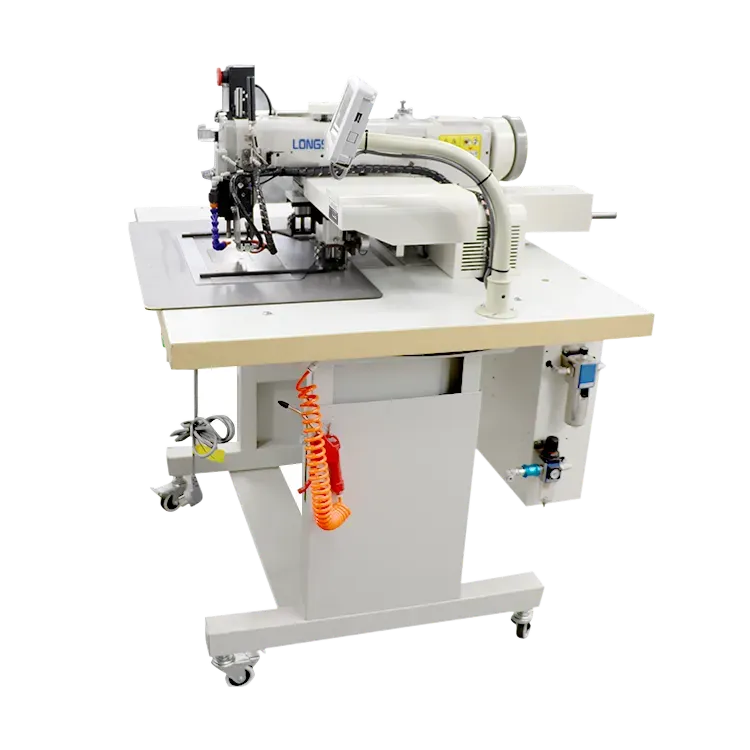

jumbo bag lock stitch machine

Moreover, advancements in technology have enabled the development of machines that can stitch multiple bags simultaneously. This capability dramatically enhances productivity, making it possible for manufacturers to meet tight deadlines and large order volumes.

Versatility and Customization

Jumbo bag lock stitch machines are incredibly versatile and can accommodate a range of bag sizes and materials. Many models come with adjustable settings, allowing operators to tailor the stitching process to meet specific requirements. Whether it’s varying the stitch length or adjusting tension settings, operators can optimize performance based on the particular type of bag being produced.

Additionally, some machines offer the option to integrate various features, such as automatic cutting and sewing for added convenience. This level of customization ensures that manufacturers can cater to diverse client needs without compromising on packaging quality.

Sustainability Considerations

As industries increasingly focus on sustainability, the jumbo bag lock stitch machine plays a role in promoting eco-friendly practices. Many jumbo bags are constructed from recyclable materials, and the longevity provided by lock stitch technology means that bags can be reused multiple times before disposal. This approach not only reduces waste but also contributes to a more sustainable production cycle.

Conclusion

The jumbo bag lock stitch machine represents a significant advancement in the field of industrial packaging. By combining efficiency, durability, and versatility, it addresses the pressing needs of modern manufacturers. As global markets continue to evolve, the reliance on reliable packaging solutions like jumbo bags and the machines that produce them is set to grow. Embracing this technology will undoubtedly enhance operational efficiencies and elevate product integrity across various industries, paving the way for a more productive and sustainable future in manufacturing and logistics.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025