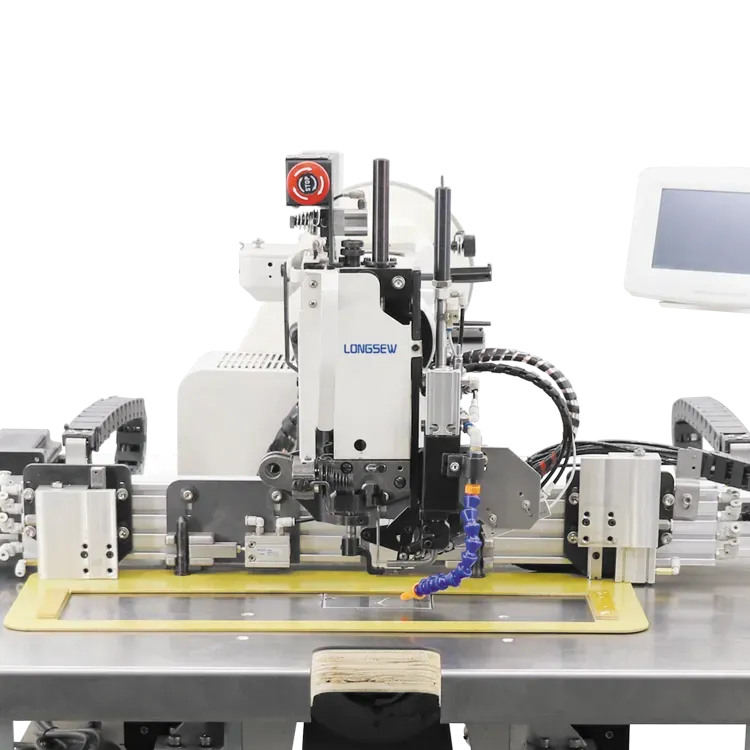

jumbo bag stitching machine

The Importance of Jumbo Bag Stitching Machines in Modern Manufacturing

In the world of manufacturing and packaging, the efficiency and reliability of processes are crucial for businesses aiming to meet growing demands. One key player in this arena is the jumbo bag stitching machine. These specialized machines have become indispensable for companies producing large bags for various industries, including agriculture, feed, chemicals, and construction.

Jumbo bags, also known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers), are designed to hold and transport bulk materials efficiently. Given their capacity to hold from 500 to 2000 kilograms, these bags play a vital role in streamlining logistics and reducing packaging costs. However, the quality of these bags relies heavily on the precision of stitching. This is where jumbo bag stitching machines come into play.

These machines are designed to handle the heavy-duty fabric used in jumbo bags. They are equipped with robust stitching mechanisms that ensure durable seams capable of withstanding the weight and stress during transportation and storage. The stitching process must be flawless to prevent any spillage of contents, which can lead to significant economic losses and safety hazards.

jumbo bag stitching machine

One of the notable features of jumbo bag stitching machines is their high-speed operation. Modern machines can produce hundreds of bags per hour, significantly increasing production efficiency. Such high throughput is essential in meeting the soaring demands of various industries without compromising quality. Moreover, these machines are automated, allowing for consistent output and reducing the margin for human error.

Another advantage is the versatility of these machines. Many models can accommodate different bag sizes and types, making them suitable for various applications. This adaptability allows manufacturers to respond quickly to market changes and customer needs, providing a competitive edge.

Maintenance is crucial for the longevity and efficiency of jumbo bag stitching machines. Regular servicing ensures that the machines operate smoothly, reducing downtime and maintaining productivity levels. Additionally, manufacturers should invest in high-quality machines known for durability and performance to ensure a good return on investment.

In conclusion, jumbo bag stitching machines play a pivotal role in modern manufacturing. Their ability to produce strong, reliable bags at high speeds helps businesses streamline their operations and meet customer demands efficiently. As industries continue to evolve, the importance of these machines will only grow, solidifying their place in the manufacturing landscape. By investing in advanced stitching technology, companies can enhance their productivity and ensure the safe transport of bulk materials across various sectors.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025