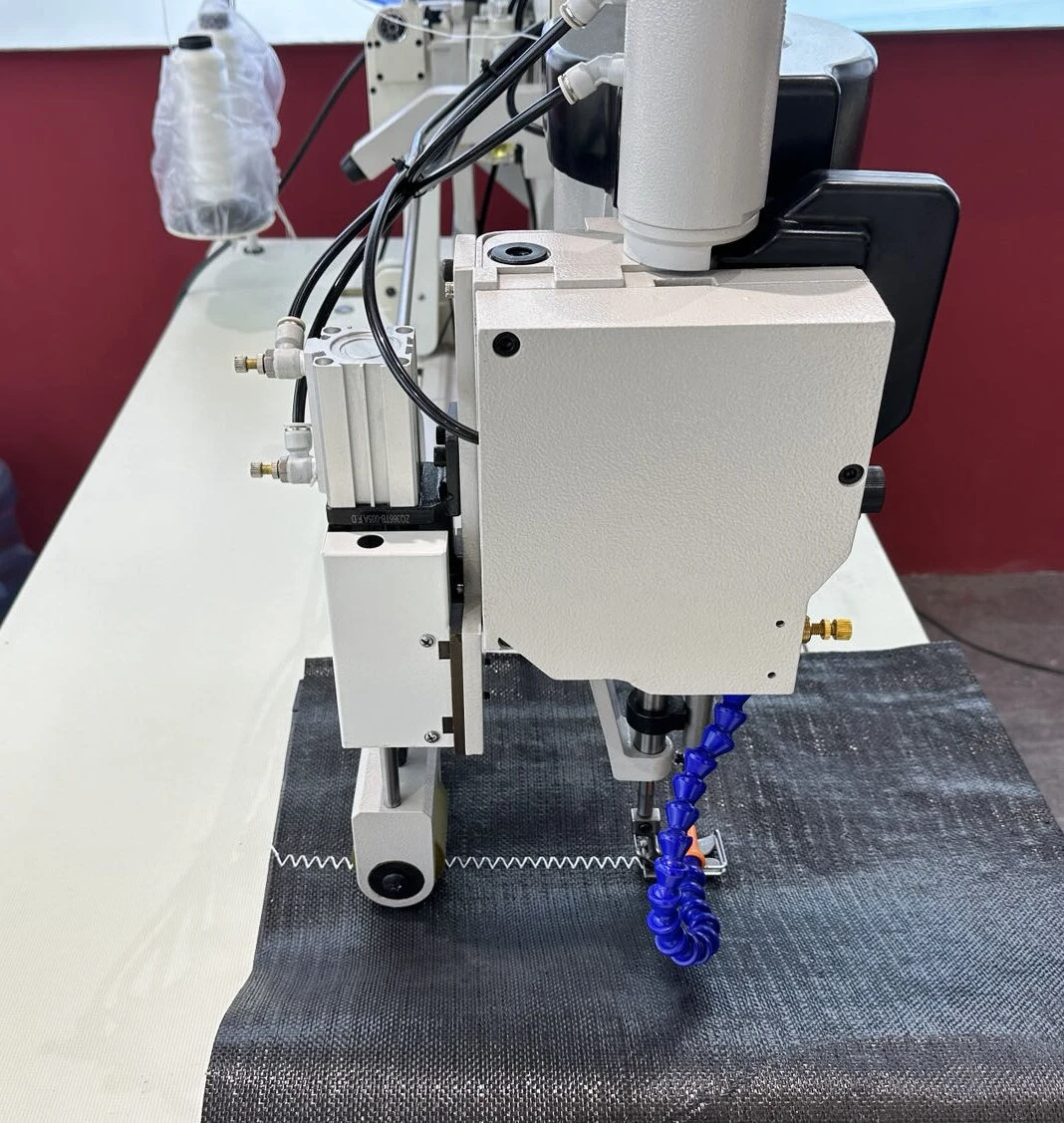

industrial zigzag sewing machine

The Industrial Zigzag Sewing Machine A Revolution in Textile Manufacturing

In the world of textile manufacturing, efficiency and versatility are key to meeting the diverse demands of the fashion and upholstery industries. Among the technological advancements that have become indispensable tools in the industry is the industrial zigzag sewing machine. This machine has transformed the way fabrics are joined, trimmed, and finished, offering enhanced capabilities that cater to a broad range of sewing applications.

Understanding the Zigzag Stitch

The zigzag stitch, a departure from the traditional straight stitch, allows for greater flexibility in stitching. It consists of a back-and-forth motion rather than a single linear movement, creating a zigzag pattern along the edge of the fabric. This unique feature offers several advantages, including stretchability and decorative appeal, making it ideal for various fabric types, including knits, wovens, and non-woven materials.

Versatility in Functional Applications

One of the main reasons the industrial zigzag sewing machine has gained immense popularity is its versatility. It can be used for a variety of tasks, including sewing hems, finishing edges, and applying decorative stitches. In garment manufacturing, the ability to create stretchable seams is particularly valuable; it allows garments to retain their shape and comfort, essential in contemporary fashion.

Additionally, zigzag stitches are commonly employed in quilting and crafting, where decorative elements enhance the visual appeal of the item. The machine can easily switch between different stitch widths and lengths, providing operators with the capability to customize their work according to specific project requirements.

Enhanced Efficiency and Productivity

Modern industrial zigzag sewing machines are designed for high-speed operation, significantly improving productivity in manufacturing environments. Equipped with powerful motors and advanced electronics, these machines can handle multiple layers of fabric with ease, reducing the time required for stitching while maintaining precision and quality. The integration of features such as automatic thread tension control and programmable stitch patterns further streamlines the sewing process.

industrial zigzag sewing machine

Moreover, the ergonomic design of contemporary zigzag sewing machines ensures that operators can work comfortably for extended periods. Some models come with an automated cutting system, allowing for quick fabric trimming after the stitch is completed, which minimizes the need for manual labor and decreases the risk of errors.

Innovations in Technology

Recent innovations have pushed the boundaries of what industrial zigzag sewing machines can do. Computerized models equipped with touch-screen interfaces allow users to select from a plethora of stitch designs, including complex patterns that were once only achievable through manual techniques. These innovations equip manufacturers with the capability to produce unique designs, catering to the personalized demands of modern consumers.

Additionally, the integration of artificial intelligence into sewing technology is on the horizon. AI-augmented sewing machines can learn from previous sewing patterns, optimizing the stitching process based on fabric type and design complexity. This not only enhances productivity but also ensures higher quality control in the manufacturing process.

Sustainability and Eco-conscious Production

As the textile industry faces increasing scrutiny regarding sustainability and environmental impact, the role of industrial zigzag sewing machines in promoting eco-conscious production becomes relevant. These machines can help reduce fabric waste by allowing more precise cuts and stitches. Furthermore, advanced features such as programmable functions enable seam optimization, cutting down on the amount of thread and material wasted during manufacturing.

Conclusion

The industrial zigzag sewing machine represents a significant advancement in textile manufacturing, offering unparalleled versatility, efficiency, and innovation. Its ability to produce stretchable seams, decorative patterns, and high-speed sewing capabilities makes it an essential tool in the garment and upholstery industries. As technology continues to evolve, these machines will likely become even more sophisticated, enabling manufacturers to meet the dynamic demands of the market while promoting sustainability within their operations. The future of textile manufacturing hinges on such innovative solutions, ensuring that creativity and functionality go hand in hand.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025