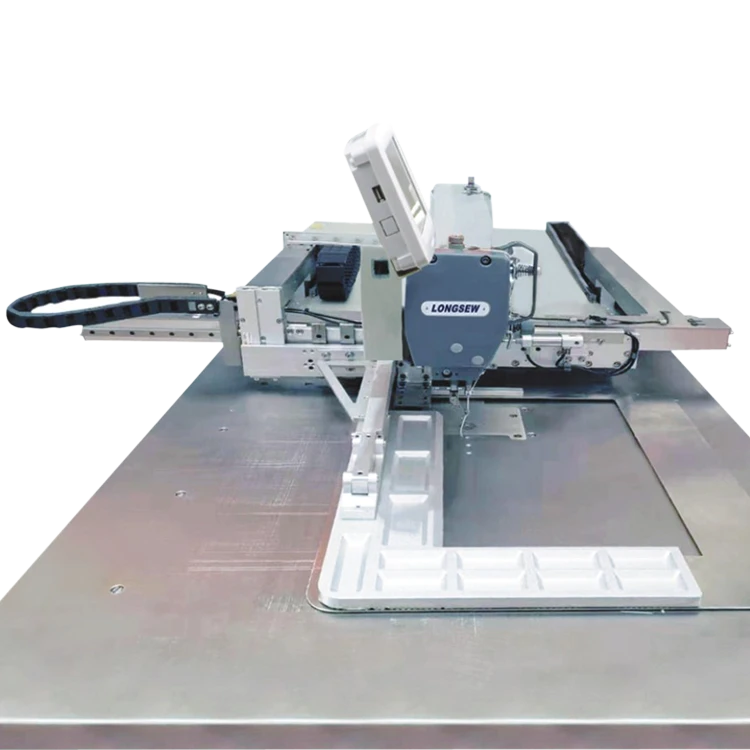

industrial walking foot machine

Exploring the Industrial Walking Foot Machine A Revolution in Sewing Technology

In the ever-evolving landscape of textile and garment manufacturing, the introduction of advanced machinery has significantly transformed production processes. One of the most remarkable innovations in this domain is the industrial walking foot machine. This specialized sewing machine has revolutionized the way heavy fabrics and multiple layers are sewn together, offering unparalleled precision, control, and efficiency.

What is a Walking Foot Machine?

At its core, a walking foot machine is a type of sewing machine that utilizes a unique feeding mechanism to move fabric through the machine. Unlike traditional machines that use a standard presser foot, the walking foot adds an additional feed mechanism that helps to walk the fabric through, ensuring that multiple layers are fed evenly. This is particularly crucial when working with thick materials such as leather, canvas, or upholstery fabrics, where uneven feeding can lead to puckering or misalignment.

The Mechanics Behind the Walking Foot

The walking foot machine typically features a dual transport system comprised of the needle feed and the walking foot feed. The needle moves up and down while the walking foot alternates with the machine's feed dogs to grip the fabric. This coordinated motion allows the fabric to be fed uniformly without shifting, making it an ideal choice for intricate sewing tasks. This mechanism not only enhances stitch quality but also reduces the likelihood of fabric damage, which can be a common challenge with heavier materials.

Advantages of Using an Industrial Walking Foot Machine

1. Sewing Precision The primary advantage of a walking foot machine is its ability to handle multiple layers of fabric with precision. This makes it particularly popular in industries that require detailed craftsmanship, such as leatherworking, upholstery, and heavy-duty garment manufacturing.

industrial walking foot machine

2. Versatility While designed for heavier fabrics, modern walking foot machines can also handle lighter materials, making them versatile tools for various applications. This adaptability allows manufacturers to switch between projects without needing to change machines.

3. Reduced Fabric Shifting One of the most significant issues encountered in sewing is fabric shifting, which can lead to uneven hems and misaligned patterns. The design of the walking foot alleviates this problem, ensuring that layers remain in position throughout the sewing process.

4. Durability Industrial walking foot machines are built to withstand the rigors of daily use in high-volume production environments. Their robust construction and powerful motors enable them to deliver consistent performance under demanding conditions.

5. User-Friendly Features Many modern walking foot machines come equipped with advanced features such as adjustable stitch length, walking foot pressure adjustment, and automatic thread cutting. These enhancements add to the overall efficiency and ease of use, making them suitable for both professionals and hobbyists.

Applications in Various Industries

The industrial walking foot machine finds its application in a multitude of industries. Leather goods manufacturers use these machines for creating wallets, belts, and bags, where precision is paramount. Upholsterers rely on walking foot machines to sew together large pieces of fabric for furniture, ensuring that seams are strong and durable. Additionally, the garment industry employs these machines for heavy-duty sewing tasks, such as making denim clothing and outdoor gear.

Conclusion

The industrial walking foot machine is a testament to the advancements in sewing technology that have shaped the fabric and textile industry. Its unique feeding mechanism and precision capabilities have made it an indispensable tool for manufacturers working with heavy and multiple layers of fabric. As industries continue to evolve, the walking foot machine will undoubtedly remain a cornerstone of high-quality craftsmanship, helping to meet the demands of consumers and producers alike. With the ongoing integration of technology, we can expect further innovations that will enhance the functionality and efficiency of these remarkable machines, paving the way for a new era in sewing and textile manufacturing.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025