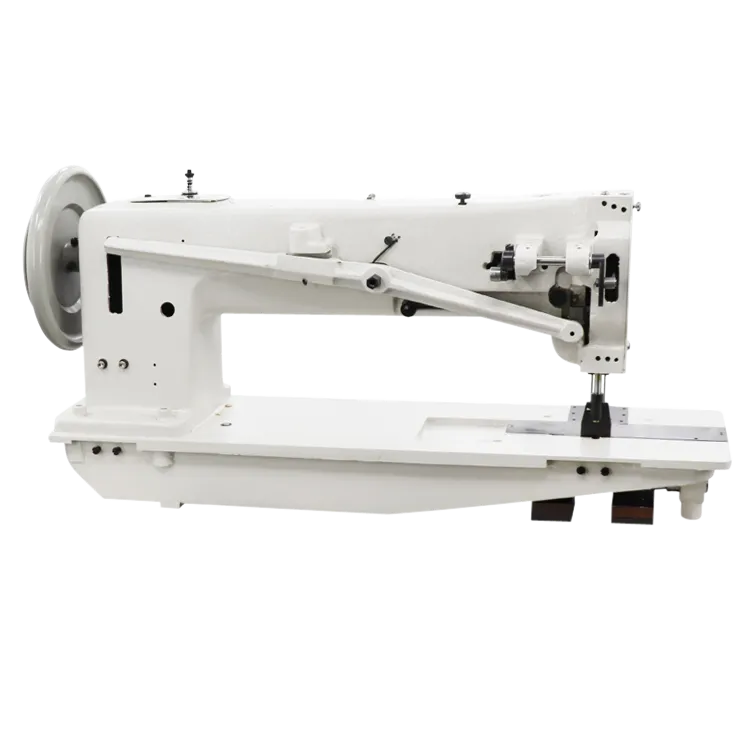

industrial upholstery machine

Industrial Upholstery Machines Revolutionizing Furniture Production

The upholstery industry has undergone significant transformations with advancements in technology, and at the forefront of this evolution are industrial upholstery machines. These specialized machines have revolutionized the way furniture is manufactured, enhancing efficiency, precision, and overall product quality.

Industrial upholstery machines are designed to meet the rigorous demands of large-scale production environments. Unlike their residential counterparts, these machines boast features that accommodate high-volume workloads, ensuring that manufacturers can keep pace with the ever-increasing demand for upholstered furniture. Equipped with robust motors and precision engineering, they offer powerful stitching capabilities and can handle a variety of materials, from leather to heavy-duty fabrics.

One of the most significant advantages of industrial upholstery machines is their ability to improve efficiency. Traditional upholstery methods often require considerable manual labor, leading to time-consuming processes. However, with modern machines, tasks such as sewing, cutting, and assembling can be executed in a fraction of the time. This increased speed not only boosts productivity but also allows manufacturers to reduce labor costs and allocate resources more effectively.

industrial upholstery machine

Moreover, industrial upholstery machines provide enhanced precision. With features such as programmable stitching patterns, automatic fabric alignment, and advanced cutting technologies, these machines ensure that every piece of furniture is crafted with uniformity and accuracy. This level of precision minimizes fabric waste and reduces the likelihood of defects, resulting in higher-quality finished products. As a result, manufacturers can uphold their reputation and customer satisfaction by delivering flawless upholstery.

Additionally, industrial upholstery machines facilitate versatility in design. Many of these machines can accommodate various styles and configurations, allowing manufacturers to experiment with different furniture designs without the need for extensive re-tooling. This flexibility not only sparks creativity but also enables companies to respond swiftly to changing market trends.

Furthermore, as sustainability becomes an increasing priority in manufacturing, industrial upholstery machines are also adapting to eco-friendly practices. Many modern machines are designed to optimize material usage and incorporate features that reduce energy consumption, contributing to greener manufacturing processes.

In conclusion, industrial upholstery machines are indispensable tools in the modern upholstery industry. With their ability to enhance efficiency, precision, and design versatility, they enable manufacturers to thrive in a competitive market. As technology continues to advance, we can expect these machines to evolve further, driving innovation and sustainability in furniture production for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025