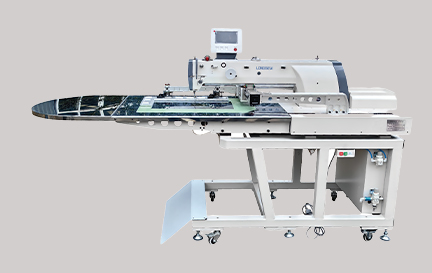

industrial single needle lock stitch machine

Industrial Single Needle Lock Stitch Machines A Comprehensive Overview

In the world of textile manufacturing, the efficiency and quality of sewing operations are paramount. One of the most vital tools in this domain is the industrial single needle lock stitch machine. This sewing machine has become a staple in factories and workshops, known for its durability, versatility, and the quality of the stitches it produces. In this article, we will explore the key features, advantages, and applications of the industrial single needle lock stitch machine.

Understanding the Single Needle Lock Stitch Machine

The single needle lock stitch machine operates on a straightforward mechanism. It consists of a needle that passes through the fabric, creating a loop of thread that intertwines with the bobbin thread to form a secure lock stitch. This method results in a tight and effective seam, which is both strong and aesthetically pleasing. The machine's design typically allows for adjustment of stitch length and tension, enabling users to customize settings according to the specific fabric being used.

Key Features

1. Simplicity and Efficiency The single needle lock stitch machine is renowned for its uncomplicated design, making it easy to operate even for novice users. Its straightforward mechanics also contribute to maintenance simplicity, often requiring minimal adjustments.

2. Stitch Quality One of the primary benefits of using a lock stitch machine is the quality of the stitches produced. The lock stitch is recognized for its strength and is less likely to unravel compared to chain stitches. This makes it an excellent choice for a range of sewing applications.

3. Versatility This type of sewing machine is capable of handling various types of fabrics, from lightweight materials like silk to heavier textiles such as denim or canvas. The adaptability to different fabric weights and textures makes it a favorite in diverse industries, including garment manufacturing, upholstery, and bag making.

4. Stitch Length and Tension Control Users can adjust the stitch length according to their needs, ranging from fine stitches for delicate fabrics to longer aggressive stitches for heavy materials. Tension control allows for perfectly balanced stitches regardless of fabric type, ensuring high-quality outputs.

industrial single needle lock stitch machine

Advantages of Using an Industrial Single Needle Lock Stitch Machine

1. Increased Production Speed Industrial models are designed for high-speed sewing, significantly enhancing production rates in manufacturing settings. This efficiency is crucial for businesses that need to meet large volume orders.

2. Cost-Effectiveness While the initial investment in an industrial sewing machine might be higher than domestic models, the durability and efficiency of these machines can lead to lower operating costs over time due to fewer repairs and replacements.

3. Enhanced Durability Built for long-term use, industrial single needle lock stitch machines can withstand continuous operation without compromising performance, making them a wise investment for production facilities.

4. Reduced Operator Fatigue Many industrial models come equipped with features such as automatic thread trimming and adjustable speed controls, which help decrease physical strain on operators while improving overall productivity.

Applications

Industrial single needle lock stitch machines are widely used across multiple sectors. In the garment industry, they are essential for constructing garments, hemming, and detailed work like buttonholes. Upholsterers utilize these machines for their sturdy seams, while bag manufacturers benefit from their ability to handle heavy materials with ease. Additionally, they are commonly employed in the production of automotive interiors and various other textile products.

Conclusion

The industrial single needle lock stitch machine is an invaluable tool in the textile industry, merging functionality with high-quality outputs. Its simplicity, adaptability, and robust design make it a go-to option for manufacturers looking to enhance their sewing operations. As the textile industry continues to evolve, these machines will undoubtedly remain at the forefront, driving innovation and efficiency in fabric processing. Whether for mass production or specialized sewing tasks, the industrial single needle lock stitch machine exemplifies the reliability and quality needed in today’s fast-paced manufacturing environment.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025