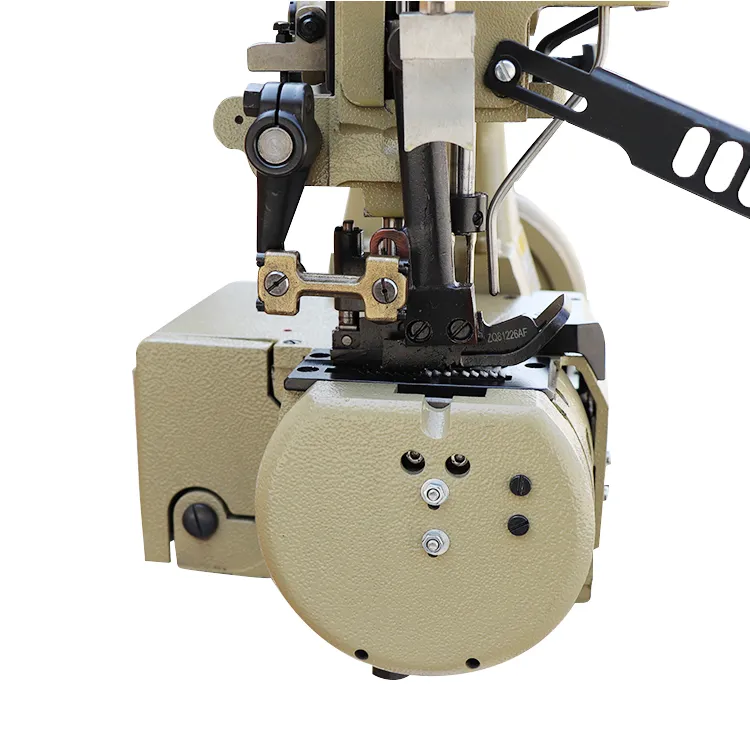

industrial cylinder arm sewing machine

The Industrial Cylinder Arm Sewing Machine A Precision Tool for Tailored Production

In the world of industrial sewing, the cylinder arm sewing machine holds a prominent place as an essential piece of equipment. Designed specifically for the sewing of cylindrical or tubular fabrics, this machine is a must-have for businesses focusing on garments like sleeves, cuffs, and other intricate parts. Understanding its functionality, advantages, and applications can provide valuable insights for manufacturers and seamstresses alike.

Design and Functionality

The industrial cylinder arm sewing machine features a unique cylindrical arm that allows for the easy manipulation of rounded shapes and narrow areas of fabric. This design element is crucial when working with items that cannot be easily sewn flat, such as the arms of shirts or the legs of pants. The machine's needle is positioned above the cylindrical arm, allowing the fabric to slide smoothly around the arm while maintaining consistent tension and alignment.

This specialized machine operates similarly to traditional flatbed sewing machines. However, the cylinder arm’s structure allows for greater ease in handling difficult shapes. Moreover, many industrial cylinder arm sewing machines come equipped with various attachments and presser feet to facilitate different sewing techniques, such as zigzag stitching or bar tacking. This versatility makes it an invaluable tool in high-rate production environments.

Advantages of Cylinder Arm Machines

One of the most significant advantages of the cylinder arm sewing machine is its ability to achieve high precision in sewing. With the precise needle positioning, seamstresses can craft intricate designs and ensure that stitches are uniformly spaced. This precision is essential in garment manufacturing, where even minor inconsistencies can affect the overall quality of the final product.

industrial cylinder arm sewing machine

The cylinder arm machine also promotes efficiency in production. By enabling easy access to hard-to-reach areas, it can decrease the overall manufacturing time for complex items. Additionally, since the fabric can be manipulated freely around the cylindrical arm, it allows for fast adjustments and reduces the likelihood of errors that could lead to fabric wastage.

Moreover, an industrial cylinder arm sewing machine often operates at higher speeds compared to its flatbed counterparts. This advantage makes it suitable for large-scale production, where meeting deadlines is crucial. Many of these machines are designed for heavy-duty use, utilizing robust materials that withstand continuous operation, thereby enhancing their longevity and reducing maintenance costs.

Applications in Industry

The applications of industrial cylinder arm sewing machines are diverse, spanning various sectors. In the apparel industry, these machines are commonly used for assembling components of garments, such as finishing sleeves, hems, and other fitted parts. Manufacturers of sportswear, workwear, and specialized outfits particularly benefit from this machine, as these products frequently require sewing in tight or awkward spaces.

In addition, the cylinder arm sewing machine is indispensable in the production of non-apparel items, including upholstery, footwear, and leather goods. For instance, the curved surfaces of shoes or the intricate stitching required for bags are effectively managed with cylinder arm technology. This adaptability makes it a go-to tool for businesses looking to produce high-quality, aesthetically pleasing products.

Conclusion

In summary, the industrial cylinder arm sewing machine is a critical asset in the realm of garment and fabric manufacturing. Its unique design caters specifically to the challenges associated with sewing cylindrical items, promoting efficiency, precision, and versatility. As industries continue to evolve, the demand for specialized machines like the cylinder arm sewing machine will undoubtedly grow. For manufacturers committed to high-quality production, investing in this technology is not merely an option but a necessity to stay competitive in the ever-increasingly demanding market. With the ability to optimize processes and enhance product quality, the cylinder arm sewing machine proves itself to be an indispensable tool for modern manufacturing.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025