Heavy-Duty Industrial Sewing Machines for Robust Fabrication and Construction Projects

The Importance of Heavy Industrial Sewing Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, the demand for durability and efficiency in production processes is more critical than ever. One of the key players in this realm is the heavy industrial sewing machine, a robust tool designed to handle the rigors of large-scale production, particularly in industries such as textiles, automotive, and upholstery. These machines have become indispensable for manufacturers looking to produce high-quality products quickly and efficiently.

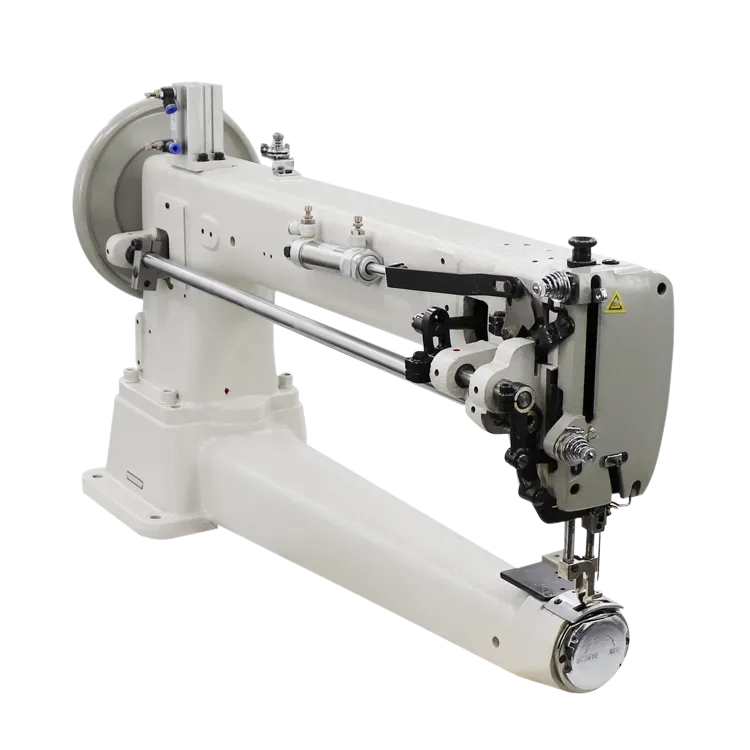

Heavy industrial sewing machines are specifically designed to sew thick materials that standard sewing machines cannot handle. They often feature powerful motors, robust construction, and specialized feeding systems that allow them to stitch through multiple layers of fabric, leather, or other tough materials. Unlike their lightweight counterparts, these machines can withstand continuous use, making them ideal for busy work environments.

One of the significant advantages of heavy industrial sewing machines is their ability to enhance productivity. With faster sewing speeds, some models can achieve up to 1,500 stitches per minute. This rapid performance dramatically reduces production time, enabling manufacturers to meet tight deadlines and respond quickly to market demands. Furthermore, many industrial sewing machines come equipped with automatic features, such as backstitching, thread trimming, and pattern sewing, which further streamline the workflow and minimize manual intervention.

Moreover, the durability of heavy industrial sewing machines contributes to cost-effectiveness in manufacturing operations. Although the initial investment for an industrial sewing machine may be higher than that of a standard sewing machine, the long-term benefits far outweigh the costs. Heavy-duty machines are built to last, requiring less maintenance and experiencing fewer breakdowns. This reliability leads to reduced downtime and lower operational costs, allowing manufacturers to maximize their profits.

heavy industrial sewing machine

In a world increasingly focused on sustainability, heavy industrial sewing machines play a pivotal role in resource efficiency. By producing quality products that can endure wear and tear, manufacturers reduce waste associated with frequent repairs or replacements. Furthermore, with advancements in technology, many industrial machines are designed with energy efficiency in mind, which helps to lower the environmental impact of manufacturing processes.

The versatility of heavy industrial sewing machines is another factor that makes them essential in various industries. They can be utilized in fabricating not only textiles but also in assembling products such as furniture upholstery, automotive interiors, and safety gear. This adaptability allows manufacturers to diversify their product offerings and enter new markets without a complete overhaul of their operations.

Despite the advantages, operators of heavy industrial sewing machines must be properly trained to maximize their potential. These machines often require a different skill set compared to traditional sewing machines. Understanding the intricacies of machine operation, tension adjustment, and troubleshooting is crucial for ensuring consistent quality in production. Therefore, investing in training is vital for manufacturers looking to harness the full capabilities of their equipment.

In conclusion, heavy industrial sewing machines are a cornerstone of modern manufacturing, offering enhanced productivity, durability, and versatility. They enable businesses to meet the demands of various industries while maintaining high-quality output. As manufacturers continue to strive for efficiency and sustainability, the significance of these machines will only grow, making them an essential investment for any forward-thinking operation. By prioritizing training and machinery maintenance, companies can ensure that they remain competitive in an ever-evolving market, all while producing exceptional products that stand the test of time.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025