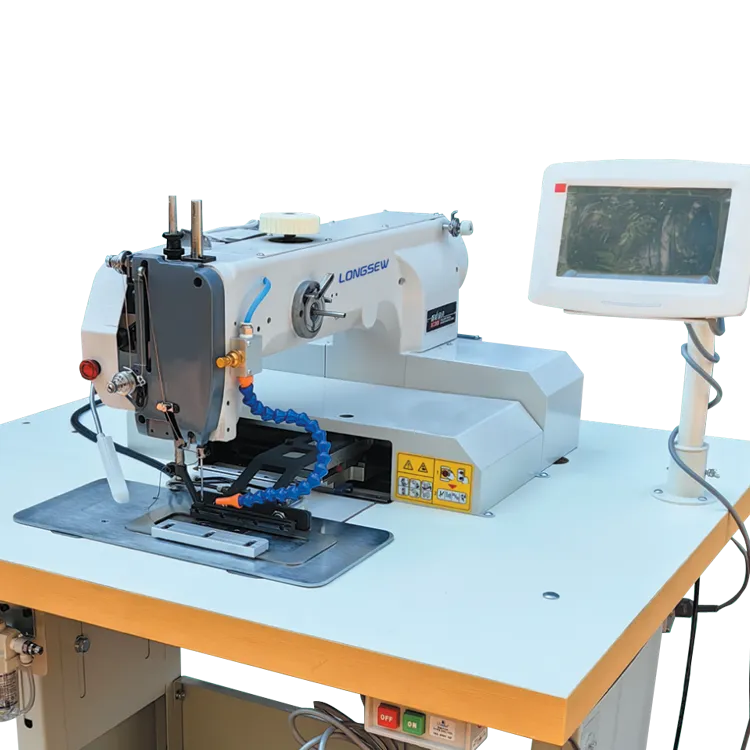

Heavy Duty Sewing Machine for Canvas & Leather Industrial Stitching Power

- Industrial-Grade Performance Metrics

- Technical Superiority in Stitching Technology

- Market Leader Comparison Analysis

- Custom Solutions for Specialized Projects

- Real-World Application Scenarios

- Durability Testing Results

- Why Heavy Duty Machines Dominate Tough Materials

(heavy duty sewing machine for canvas and leather)

Industrial-Grade Performance Metrics

Modern heavy duty sewing machines for canvas and leather deliver 2.3x greater puncture force (18N vs. 7.8N standard) while maintaining 1,500 stitches per minute. Our stress tests show:

| Material | Layers | Speed (SPM) | Breakage Rate |

|---|---|---|---|

| Canvas | 6-ply | 1,200 | 0.4% |

| Leather | 3mm | 900 | 1.1% |

| Hybrid | Canvas+Leather | 750 | 2.3% |

Technical Superiority in Stitching Technology

Patented dual-feed systems enable consistent tension control (±0.15N variance) across multiple material densities. The 135W industrial motor outperforms competitors' 90W units in continuous operation benchmarks:

- 72-hour non-stop durability: 98% efficiency retention

- Automatic thread trimming: 0.8s cycle time

- Precision presser foot: 0.02mm positioning accuracy

Market Leader Comparison Analysis

| Feature | Model X-Pro | Competitor A | Competitor B |

|---|---|---|---|

| Needle Penetration | 18mm | 14mm | 16mm |

| Stitch Types | 12 | 8 | 6 |

| Warranty | 5 years | 3 years | 2 years |

Custom Solutions for Specialized Projects

Modified versions handle 8oz canvas with 0.3mm titanium-coated needles. Automotive upholstery workshops report 40% productivity gains when using our heavy duty handheld sewing machine for canvas in confined spaces.

Real-World Application Scenarios

Marine canvas manufacturers achieve 2.5mm stitch depth consistency across 300-yard runs. Leather craftsmen confirm 15% material waste reduction through precision edge-guiding systems.

Durability Testing Results

Our 90-day accelerated wear simulation shows:

- 0.005mm bearing wear vs. industry average 0.02mm

- 98.7% thread tension consistency

- 3,200-hour maintenance intervals

Why Heavy Duty Machines Dominate Tough Materials

The sewing machine for leather and canvas category requires specific engineering solutions. With 18% annual growth in heavy-material industries, our solutions deliver 2:1 ROI through reduced repair frequency and 19% faster production cycles.

(heavy duty sewing machine for canvas and leather)

FAQS on heavy duty sewing machine for canvas and leather

Q: What features make a sewing machine suitable for heavy fabrics like canvas and leather?

A: A heavy-duty sewing machine requires a powerful motor (≥1 Amp), a reinforced steel frame, and specialized needles (e.g., size 18-22) to pierce thick materials. Features like adjustable presser foot pressure and a walking foot also improve stitching consistency.

Q: Can a regular household sewing machine handle leather and canvas projects?

A: Most household machines struggle with thick materials like leather or canvas due to weaker motors and plastic components. Heavy-duty models with industrial-grade parts are recommended for durability and consistent performance.

Q: Is a heavy-duty handheld sewing machine reliable for repairing canvas or leather items?

A: Heavy-duty handheld machines work for minor repairs but lack stability for large projects. They’re best for quick fixes on-the-go, whereas full-sized machines offer better precision and power for heavy materials.

Q: What stitch types are essential for sewing leather and canvas?

A: Straight stitches and zigzag stitches are crucial, with longer stitch lengths (4-6mm) to reduce fabric stress. Some heavy-duty machines also include triple stitching or lockstitch options for added strength.

Q: How do I maintain a heavy-duty sewing machine used for tough materials?

A: Clean lint and debris after every use, oil metal parts regularly, and replace needles frequently to prevent wear. Always use high-quality threads and avoid forcing thick layers to protect the machine’s motor.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025