FIBC Bag Sewing Machines for Efficient Manufacturing and High-Quality Production

The Role of FIBC Sewing Machines in Modern Manufacturing

In the realm of industrial manufacturing, the production of Flexible Intermediate Bulk Containers (FIBCs), commonly known as big bags, has become increasingly significant. These versatile containers are used extensively across various industries for transporting bulk materials such as grains, chemicals, fertilizers, and construction materials. Central to the production of FIBCs is the sewing machine utilized to stitch the fabrics, ensuring durability and reliability. This article delves into the importance of FIBC sewing machines, their features, and their impact on the manufacturing process.

Understanding FIBC and Its Applications

Flexible Intermediate Bulk Containers are large, flexible bags typically made from woven polypropylene or other durable materials. FIBCs have revolutionized the way bulk materials are stored and transported due to their capacity, lightweight design, and the ability to hold large quantities of materials safely. Industries ranging from agriculture to construction benefit from using FIBCs, as they provide a cost-effective and efficient solution for bulk handling.

The Necessity of Specialized Sewing Machines

The manufacturing of FIBCs requires precision and strength, making the choice of sewing machinery critical. FIBC sewing machines are specially designed to handle thick, heavy fabrics that conventional sewing machines cannot manage. These machines are engineered to create strong seams that can withstand the weight and stress of filled containers, ensuring that the bags do not tear or leak during transportation.

Features of FIBC Sewing Machines

1. Heavy-Duty Construction FIBC sewing machines are built with robust components to handle the demands of heavy fabrics. They often feature powerful motors capable of sewing through multiple layers of material without jamming.

2. Large Sewing Area The design of these machines typically includes a larger sewing area to accommodate the size of the FIBCs, which can be several feet in height and width.

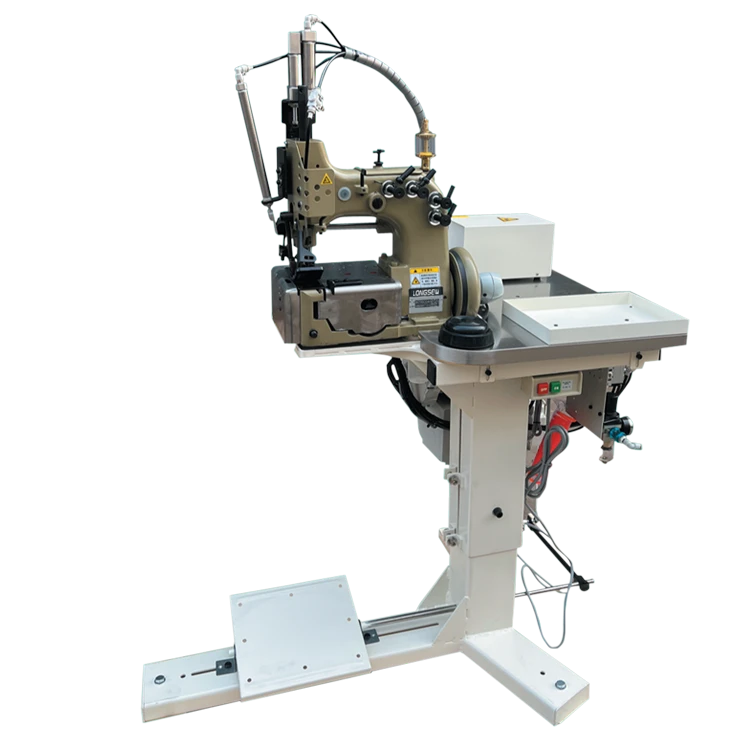

fibc sewing machine

3. Versatile Stitching Options Manufacturers can choose from various stitching types, including lockstitch and overlock stitches, depending on the specific requirements of the FIBC being produced. This versatility allows for customization according to the application.

4. Automatic Functions Many modern FIBC sewing machines come equipped with automated features that enhance efficiency and reduce labor costs. These functions may include automated thread delivery, cutting systems, and user-friendly controls for ease of operation.

5. Durability and Maintenance Given the heavy-duty nature of the work, FIBC sewing machines are designed for longevity and ease of maintenance, minimizing downtime in production.

The Impact on Efficiency and Quality

The integration of FIBC sewing machines in the manufacturing process significantly boosts production efficiency. High-speed sewing capabilities enable manufacturers to produce large quantities of bags quickly, meeting high-demand periods with ease. Furthermore, the precision offered by these machines ensures the quality of the seams, reducing the likelihood of defects that could lead to product loss or customer dissatisfaction.

In addition to efficiency, the use of specialized sewing machinery enhances safety. Strongly sewn FIBCs reduce the risks associated with transporting bulk materials, as they are less likely to rupture under stress. This reliability is crucial in industries where the safety of personnel and the integrity of materials are paramount.

Conclusion

FIBC sewing machines represent a critical component in the manufacturing of modern bulk containers. Their specialized design, robust features, and ability to enhance production efficiency make them indispensable in a wide variety of applications. As industries continue to evolve and demand more from packaging solutions, the role of FIBC sewing machines will likely expand, driving innovation and productivity in the manufacturing sector. By investing in advanced sewing technology, companies can ensure they remain competitive while delivering high-quality products to their customers.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025